The Critical Importance of Track Geometry Measurement

Track geometry refers to the spatial and geometric characteristics of railway tracks, including parameters that define the position and orientation of the rails. Proper track geometry is fundamental to safe and efficient railway operations for several reasons:

- Safety Assurance: Deviations in track geometry can lead to derailments, especially at high speeds. According to industry data, poor track geometry accounts for over one-third of all train accidents.

- Ride Quality: Optimal track geometry ensures passenger comfort by minimizing vibrations and lateral movements during travel.

- Asset Longevity: Regular monitoring and maintenance of track geometry extend the service life of both track infrastructure and rolling stock by reducing wear and stress.

- Operational Efficiency: Well-maintained tracks allow for higher speeds and heavier loads, improving overall system capacity and performance.

- Maintenance Optimization: Accurate measurement enables condition-based maintenance strategies, reducing costs by targeting interventions where they’re most needed.

The economic impact of track geometry defects is substantial. A single major derailment can cost millions in direct damages, not including indirect costs from service disruptions and reputational damage. According to a report by the American Railway Engineering and Maintenance-of-Way Association (AREMA), preventive maintenance based on accurate geometry measurements can reduce overall maintenance costs by up to 15-20% compared to reactive approaches.

Key Track Geometry Parameters

Before delving into measurement techniques, it’s essential to understand the primary track geometry parameters that require monitoring:

Alignment

The lateral position of the track in the horizontal plane. Deviations in alignment can cause lateral forces that may lead to derailments, especially in curves. Alignment is typically measured as the mid-chord offset (MCO) from a reference line.

Profile

The vertical position of the track in the longitudinal plane. Irregularities in profile affect ride quality and can cause excessive vertical accelerations. Like alignment, profile is often measured as a mid-chord offset in the vertical plane.

Gauge

The distance between the inner faces of the rails. Gauge widening can lead to wheel drops between rails, while gauge narrowing can cause wheel climbing and derailment. Standard gauge is 1,435mm (4ft 8.5in) in most countries.

Cross-level

The difference in elevation between the two rails at a given point. Improper cross-level can cause uneven wheel loading and potential derailment, especially in combination with other geometry defects.

Twist

The rate of change in cross-level over a specified distance. Excessive twist can lead to wheel unloading and is particularly dangerous in combination with other geometry defects.

Curvature

The degree of track bending in the horizontal plane. Proper curvature measurement ensures trains can navigate turns safely at appropriate speeds without excessive lateral forces.

These parameters are interrelated, and defects rarely occur in isolation. For example, a twist defect combined with gauge widening presents a significantly higher derailment risk than either defect alone. This complexity necessitates comprehensive measurement techniques that can capture multiple parameters simultaneously.

Manual vs. Automated Track Geometry Measurement

Track geometry measurement has evolved significantly over the decades, from labor-intensive manual methods to sophisticated automated systems. Both approaches continue to play important roles in modern railway maintenance:

Manual Measurement Methods

- Track Gauge: Handheld gauges measure the distance between rails.

- String Line Method: A string stretched between two points on the rail with measurements taken at the midpoint to determine alignment and profile.

- Track Geometry Trolleys: Manually pushed carts equipped with basic measurement tools.

- Optical Survey Equipment: Total stations and levels used for precise measurement of track position.

- Versine Measurement: Using chord and offset measurements to determine track curvature.

Advantages

- Low initial investment

- No complex technology requirements

- Suitable for spot checks and small sections

- Can be deployed quickly without scheduling specialized equipment

- Useful in areas inaccessible to larger measurement vehicles

Automated Measurement Systems

- Track Geometry Cars: Dedicated vehicles equipped with multiple sensors.

- Inertial Measurement Systems: Using accelerometers and gyroscopes to create track profiles.

- Optical/Laser Systems: Non-contact measurement using cameras and lasers.

- In-Service Vehicles: Regular trains equipped with measurement systems.

- Autonomous Track Geometry Measurement Systems (ATGMS): Uncrewed systems that can be mounted on revenue service trains.

Advantages

- High measurement speed (up to 320 km/h)

- Continuous data collection over long distances

- Higher accuracy and repeatability

- Multiple parameter measurement simultaneously

- Real-time data processing and defect detection

| Aspect | Manual Methods | Automated Systems |

| Measurement Speed | Slow (1-2 km/hour) | Fast (up to 320 km/hour) |

| Data Density | Discrete points, typically every 5-10m | Continuous, every few centimeters |

| Labor Requirements | High (multiple personnel) | Low (1-2 operators) |

| Initial Cost | Low ($1,000-$10,000) | High ($500,000-$5 million) |

| Operational Cost | High per kilometer | Low per kilometer |

| Accuracy | Moderate (±2-5mm) | High (±0.5-1mm) |

| Data Processing | Manual, time-consuming | Automated, real-time |

| Track Access Requirements | Requires track possession | Can operate during normal service |

The choice between manual and automated methods depends on factors including network size, traffic density, speed requirements, and available resources. Many railways employ a hybrid approach, using automated systems for regular network-wide inspection and manual methods for verification and specific problem areas.

5 Modern Track Geometry Measurement Techniques

The evolution of technology has led to several sophisticated approaches for measuring track geometry. Here are five cutting-edge techniques currently employed in the industry:

1. Inertial Measurement Systems

Inertial Measurement Systems represent one of the most widely adopted technologies for track geometry assessment. These systems utilize accelerometers and gyroscopes to measure the motion of a vehicle as it travels along the track.

How It Works:

- Accelerometers measure vertical and lateral accelerations experienced by the vehicle.

- Gyroscopes measure angular velocities around three axes.

- The data is integrated twice to obtain position information, creating a space curve that represents the track geometry.

- Reference systems compensate for vehicle dynamics to isolate track geometry from vehicle motion.

- Advanced algorithms filter the data to remove noise and drift inherent in inertial measurements.

Key Advantages:

- High measurement speeds (up to 320 km/h)

- Ability to measure at normal service speeds without special track access

- Comprehensive data collection for multiple parameters simultaneously

- Relatively compact equipment that can be installed on various vehicle types

- Mature technology with proven reliability

A notable example is the ENSCO Track Geometry Measurement System, which uses inertial technology to provide comprehensive track geometry data at speeds up to 175 mph. The system has been deployed by major railroads including BNSF and Union Pacific, as well as the FRA’s Automated Track Inspection Program (ATIP).

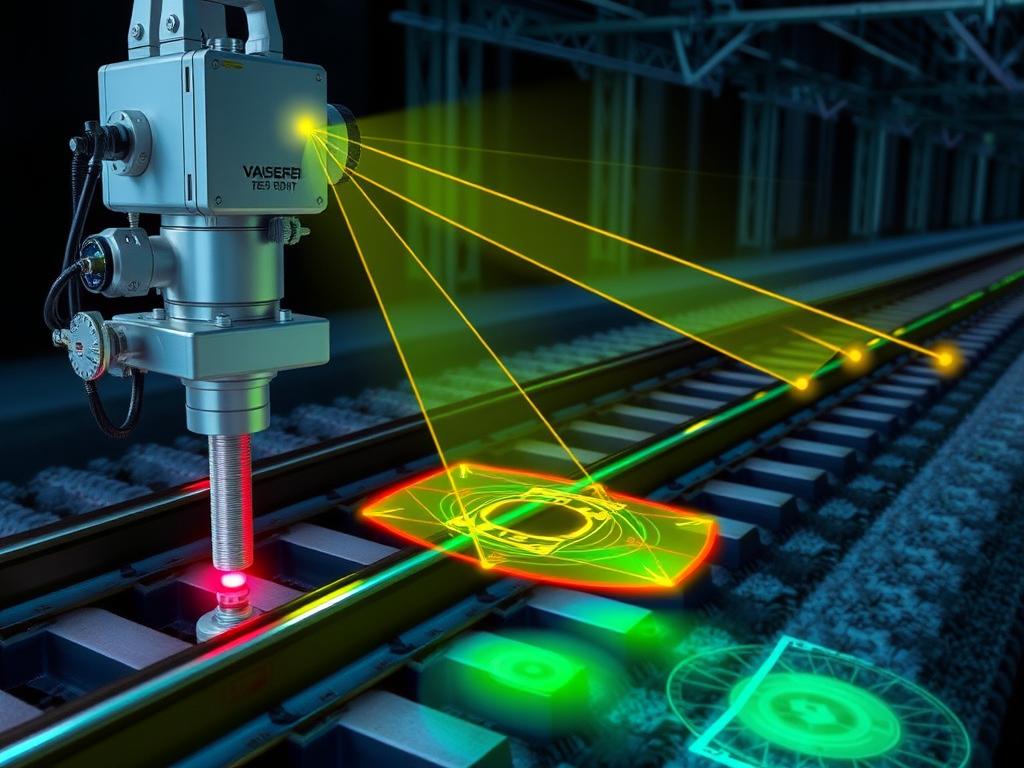

2. Optical/Laser-Based Systems

Optical and laser-based systems provide non-contact measurement of track geometry using various light-based technologies. These systems have gained popularity due to their high precision and immunity to certain environmental factors.

How It Works:

- Laser sources project beams onto the rail surface at precise angles.

- High-speed cameras capture the position of the laser light on the rail.

- Triangulation principles determine the exact position and profile of the rail.

- Multiple laser/camera pairs measure different aspects of track geometry simultaneously.

- Computer vision algorithms process the images to extract geometric parameters.

Key Advantages:

- Extremely high accuracy (sub-millimeter in ideal conditions)

- No physical contact with the rail, reducing wear on measurement equipment

- Ability to capture detailed rail profile information beyond basic geometry

- Less susceptible to mechanical vibrations than contact-based systems

- Can detect surface defects in addition to geometric parameters

The Plasser & Theurer EM120 track recording car employs optical systems that can measure up to 16 different track parameters simultaneously at speeds up to 120 km/h. This system has been successfully implemented by Network Rail in the UK and Deutsche Bahn in Germany.

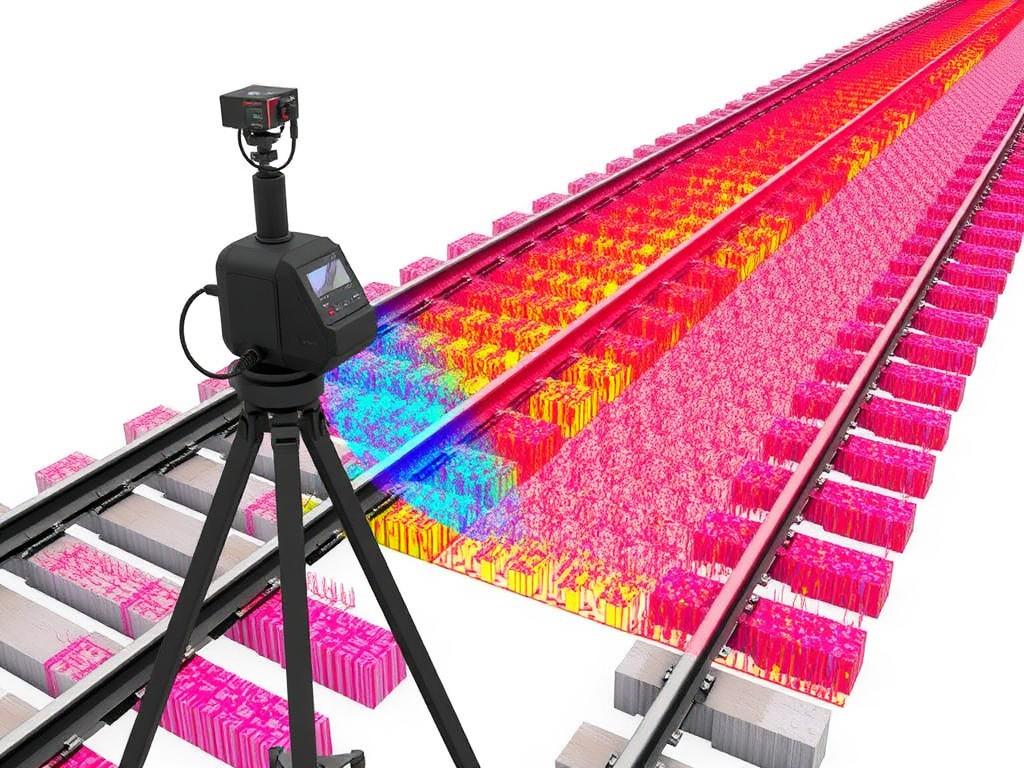

3. LiDAR and 3D Scanning Technology

Light Detection and Ranging (LiDAR) technology has revolutionized track geometry measurement by providing comprehensive 3D models of the entire track structure and surrounding environment.

How It Works:

- LiDAR sensors emit laser pulses that reflect off surfaces and return to the sensor.

- The time-of-flight principle determines the distance to each point.

- Rotating mirrors or multiple sensors create a 360° field of view.

- The result is a dense 3D point cloud representing the track and surroundings.

- Specialized algorithms extract track geometry parameters from the point cloud.

Key Advantages:

- Captures the entire track environment, not just the rails

- Provides context for geometry issues (e.g., drainage problems, vegetation encroachment)

- Creates a digital twin of the infrastructure for advanced analysis

- Enables clearance assessment and structure gauging simultaneously

- Supports comprehensive asset management beyond geometry measurement

Bentley Systems’ rail measurement solution combines mobile LiDAR with specialized software to create detailed digital twins of railway corridors. This approach has been adopted by SNCF in France to integrate track geometry data with broader infrastructure management.

4. GPS-Based Measurement Systems

Global Positioning System (GPS) technology, often enhanced with additional reference systems, provides absolute positioning capabilities for track geometry measurement. These systems are particularly valuable for long-term monitoring of track movement and settlement.

How It Works:

- High-precision GPS receivers (RTK-GPS) determine absolute position coordinates.

- Reference stations or networks provide correction data to achieve centimeter-level accuracy.

- Inertial systems often complement GPS to fill gaps in satellite coverage (tunnels, dense urban areas).

- Sophisticated algorithms combine multiple data sources through sensor fusion.

- The absolute track position is compared to design values to identify deviations.

Key Advantages:

- Provides absolute positioning in global coordinate systems

- Enables long-term monitoring of track movement and settlement

- Facilitates integration with GIS and asset management systems

- Supports tamping and maintenance operations with precise location data

- Particularly valuable for newly constructed lines and monitoring critical infrastructure

Amberg Technologies’ GRP System FX combines precision GPS with total station measurements to provide absolute track geometry with millimeter accuracy. This system has been used extensively in the construction and monitoring of high-speed lines in Europe and Asia.

5. Autonomous and In-Service Measurement Systems

The latest evolution in track geometry measurement involves autonomous systems that can be mounted on regular service vehicles, enabling frequent monitoring without dedicated inspection runs.

How It Works:

- Compact measurement systems are installed on regular passenger or freight trains.

- Data collection occurs during normal service operations.

- Wireless communication transmits data to central servers in near real-time.

- Cloud-based processing analyzes the data and generates alerts for detected defects.

- Machine learning algorithms improve detection accuracy over time and predict deterioration.

Key Advantages:

- Dramatically increased measurement frequency (daily instead of monthly/quarterly)

- No need for dedicated inspection vehicles or track possession

- Early detection of developing defects through trend analysis

- Cost-effective deployment across large networks

- Supports predictive maintenance strategies through continuous monitoring

MERMEC’s ERTMS Integrated Measuring System (EIMS) can be installed on regular passenger trains and has been deployed by Italian Railways (FS) to monitor high-speed lines daily without disrupting service. The system has demonstrated the ability to detect developing geometry defects weeks before they would reach intervention thresholds.

Want to explore these techniques in greater detail?

Download our comprehensive technical guide on track geometry measurement systems, including detailed specifications, implementation considerations, and case studies from leading railways worldwide.

Key Technologies Enabling Advanced Track Geometry Measurement

Several enabling technologies have contributed to the rapid advancement of track geometry measurement capabilities:

Advanced Sensors

- MEMS Accelerometers: Miniature electromechanical systems providing high-precision acceleration measurements at low cost.

- Fiber Optic Gyroscopes: Offering superior stability and accuracy compared to mechanical gyroscopes.

- High-Speed Cameras: Capable of capturing thousands of frames per second for detailed optical measurements.

- Solid-State LiDAR: Compact, reliable laser scanning without moving parts.

Data Processing Systems

- Edge Computing: Processing data onboard measurement vehicles to reduce transmission requirements.

- Signal Processing Algorithms: Advanced filtering and correction techniques to improve measurement accuracy.

- Real-Time Analysis: Immediate detection and alerting for critical defects.

- Cloud Computing: Scalable resources for processing massive datasets from network-wide deployments.

Data Analytics Tools

- Machine Learning: Automated defect detection and classification with improving accuracy over time.

- Predictive Analytics: Forecasting track degradation based on historical measurements.

- Digital Twins: Virtual representations of physical assets for simulation and analysis.

- Visualization Tools: Interactive interfaces for exploring complex geometry data.

The integration of these technologies has transformed track geometry measurement from a periodic inspection activity to a continuous monitoring process that supports data-driven maintenance decision-making. Railways can now detect and address geometry issues before they become safety concerns, optimizing both safety and maintenance efficiency.

Industry Standards and Regulatory Framework

Track geometry measurement is governed by various standards and regulations that define acceptable parameters, measurement methods, and intervention thresholds. These standards vary by region and track class but share common principles:

European Standards

- EN 13848 Series: The primary European standard for track geometry measurement, divided into multiple parts:

- EN 13848-1: Characterization of track geometry

- EN 13848-2: Measuring systems in track recording vehicles

- EN 13848-3: Measuring systems in track construction and maintenance machines

- EN 13848-4: Measuring systems in manual devices

- EN 13848-5: Geometric quality levels and limit values

- EN 13848-6: Characterization of track geometry quality

- TSI Infrastructure: Technical Specifications for Interoperability defining requirements for European railway networks.

North American Standards

- FRA Track Safety Standards (49 CFR Part 213): Defines track geometry requirements based on track class and speed.

- AREMA Manual for Railway Engineering: Provides recommended practices for track geometry measurement and maintenance.

- Transport Canada Track Safety Rules: Similar to FRA standards but with specific Canadian requirements.

| Parameter | FRA Class 4 (60 mph) | FRA Class 6 (110 mph) | EN 13848 (160 km/h) |

| Gauge Widening | ≤ 1.25″ | ≤ 0.75″ | ≤ 20mm |

| Gauge Narrowing | ≤ 0.5″ | ≤ 0.5″ | ≤ 3mm |

| Alignment (62′ chord) | ≤ 1.25″ | ≤ 0.5″ | ≤ 8mm (D1) |

| Profile (62′ chord) | ≤ 1.25″ | ≤ 0.5″ | ≤ 8mm (D1) |

| Cross-level | ≤ 1.25″ | ≤ 0.5″ | ≤ 7mm |

| Twist (62′ base) | ≤ 1.25″ | ≤ 0.75″ | ≤ 5mm |

Recent regulatory developments have increasingly recognized the value of automated track geometry measurement. For example, the FRA has proposed regulations requiring Class I and II railroads, as well as passenger railroads, to operate qualifying Track Geometry Measurement Systems (TGMS) at specified frequencies on mainline and controlled siding tracks. This shift reflects the growing consensus that regular automated measurement is essential for maintaining safety on modern railway networks.

Real-World Implementation Examples

Several railway operators worldwide have implemented advanced track geometry measurement systems with impressive results:

Deutsche Bahn’s DIANA System

Germany’s Deutsche Bahn operates the Diagnostic and Analysis system DIANA, which combines multiple measurement technologies on specialized vehicles. The system includes:

- Inertial measurement units for track geometry

- Optical systems for rail profile measurement

- Ground-penetrating radar for substructure assessment

- Overhead line measurement systems

Since implementing DIANA, Deutsche Bahn has reported:

- 30% reduction in geometry-related speed restrictions

- 15% decrease in maintenance costs through optimized intervention planning

- Improved track quality index across the high-speed network

The system inspects over 60,000 km of track annually, providing comprehensive data for maintenance planning and quality assurance.

BNSF Railway’s Autonomous Track Geometry Program

BNSF Railway in the United States has pioneered the use of autonomous track geometry measurement systems (ATGMS) installed on regular freight trains. Their implementation includes:

- Multiple ATGMS units distributed across the network

- Daily measurement of critical corridors

- Real-time data transmission to centralized analysis systems

- Integration with maintenance management platforms

The results have been significant:

- Over 50% increase in measurement frequency without additional track access requirements

- 25% reduction in geometry-related derailments over a five-year period

- Improved ability to detect and address seasonal track issues (e.g., sun kinks, frost heave)

- Enhanced trending analysis enabling predictive maintenance

BNSF’s implementation demonstrates how modern measurement technology can be integrated into regular operations without dedicated inspection vehicles.

Network Rail’s Plain Line Pattern Recognition (PLPR)

The UK’s Network Rail has developed an innovative system combining track geometry measurement with automated visual inspection. The PLPR system includes:

- High-speed cameras capturing images of track components

- Laser-based geometry measurement

- Machine learning algorithms for automated defect detection

- Integration with Network Rail’s asset management systems

Since implementation, Network Rail has achieved:

- 40% reduction in manual visual inspections

- Increased inspection speeds from 5 mph (walking inspection) to 125 mph

- Improved detection rates for early-stage defects

- Enhanced safety through reduced trackside working

The PLPR system now covers over 15,000 miles of track annually, providing comprehensive data on both geometry and visual condition.

These case studies demonstrate how modern track geometry measurement systems can deliver significant safety and efficiency benefits when properly implemented and integrated with maintenance processes.

Challenges in Track Geometry Measurement

Despite significant technological advances, several challenges remain in the field of track geometry measurement:

Environmental Factors

- Weather Conditions: Rain, snow, and extreme temperatures can affect sensor performance and measurement accuracy.

- Lighting Variations: Optical systems may struggle in low light, direct sunlight, or rapidly changing conditions (tunnels, bridges).

- Contamination: Dust, oil, and debris on rails can interfere with optical measurements and affect contact-based systems.

- Vegetation: Overgrowth can obstruct sensors and create false readings in some systems.

Technical Limitations

- Inertial Drift: Accumulated errors in inertial systems requiring periodic correction.

- GPS Signal Loss: In tunnels, deep cuttings, and urban canyons.

- Data Volume: Managing and processing terabytes of measurement data efficiently.

- Power Requirements: Ensuring sufficient power for autonomous systems on regular vehicles.

- Integration Challenges: Combining data from multiple measurement technologies.

Operational Challenges

- Track Access: Scheduling measurement runs on busy networks.

- Calibration: Maintaining system accuracy through regular calibration.

- Data Interpretation: Translating measurements into actionable maintenance decisions.

- Legacy Integration: Connecting modern systems with existing maintenance processes.

- Skills Gap: Training personnel to operate and maintain sophisticated measurement systems.

Addressing these challenges requires a combination of technological innovation, operational adaptation, and organizational change. Railways are increasingly adopting integrated approaches that combine multiple measurement technologies to overcome the limitations of individual systems.

Future Trends in Track Geometry Measurement

The field of track geometry measurement continues to evolve rapidly, with several emerging trends likely to shape its future:

AI and Machine Learning Integration

Artificial intelligence is transforming track geometry measurement through:

- Automated defect detection with improving accuracy over time

- Predictive analytics forecasting geometry degradation before critical thresholds are reached

- Anomaly detection identifying unusual patterns that may indicate developing issues

- Optimization algorithms determining ideal maintenance interventions and timing

- Computer vision enhancing optical measurement capabilities

IoT-Enabled Continuous Monitoring

The Internet of Things is enabling new approaches to track monitoring:

- Distributed sensor networks providing continuous data from fixed locations

- Interconnected measurement systems sharing data across platforms

- Edge computing processing data locally to reduce transmission requirements

- Cloud-based analytics platforms integrating data from multiple sources

- Real-time alerting systems notifying maintenance teams of developing issues

Integration with Digital Twins

Digital twin technology is creating virtual representations of physical assets:

- Comprehensive models incorporating geometry, component condition, and usage data

- Simulation capabilities predicting the impact of maintenance interventions

- Visualization tools making complex data accessible to decision-makers

- Integration with BIM (Building Information Modeling) for infrastructure management

- Life-cycle modeling optimizing long-term asset management strategies

Emerging Technologies to Watch

Drone-Based Inspection

Unmanned aerial vehicles (UAVs) equipped with cameras and LiDAR are being tested for track geometry inspection, particularly in hard-to-reach areas or following natural disasters. These systems offer rapid deployment without track access requirements, though currently with lower precision than vehicle-based systems.

Satellite-Based Monitoring

Advanced InSAR (Interferometric Synthetic Aperture Radar) techniques can detect millimeter-scale ground movement from satellites. While not replacing traditional geometry measurement, these methods can identify areas of track settlement or movement requiring closer inspection.

Augmented Reality for Maintenance

AR systems are being developed to overlay geometry measurement data onto the physical track during maintenance operations, helping workers visualize defects and verify corrections in real-time.

Blockchain for Data Integrity

Blockchain technology is being explored to ensure the integrity and traceability of track geometry data, particularly important for regulatory compliance and safety certification.

These emerging technologies and approaches promise to further enhance the safety, efficiency, and cost-effectiveness of track geometry measurement. Railways that embrace these innovations will be better positioned to meet the increasing demands for safety, reliability, and capacity on modern networks.

Conclusion: The Future of Track Safety

Track geometry measurement has evolved from simple manual methods to sophisticated automated systems capable of detecting millimeter-scale deviations at high speeds. This evolution has contributed significantly to railway safety, with geometry-related derailments decreasing despite increasing speeds and loads on modern networks.

The integration of advanced sensors, data analytics, and artificial intelligence is transforming track geometry measurement from a periodic inspection activity to a continuous monitoring process that supports predictive maintenance strategies. This shift enables railways to address geometry issues before they become safety concerns, optimizing both safety and maintenance efficiency.

As railway networks continue to face increasing demands for capacity, reliability, and safety, advanced track geometry measurement techniques will play an increasingly critical role in infrastructure management. Railways that embrace these technologies and integrate them effectively into their maintenance processes will be better positioned to meet these challenges while controlling costs and enhancing safety.

Need expert guidance on track geometry measurement?

Our team of railway engineering specialists can help you assess your current measurement systems, identify opportunities for improvement, and develop a customized implementation plan for your network.