The world of textile engineering is revolutionizing the way we think about fabrics and their applications. With advancements in textile technology, the industry is witnessing a significant shift towards innovative and sustainable materials.

The textile industry has come a long way, from traditional weaving techniques to cutting-edge fabric engineering. Today, textile engineers are pushing the boundaries of what is possible, creating materials that are not only aesthetically pleasing but also functional and sustainable.

Key Takeaways

- The textile industry is undergoing a significant transformation with advancements in textile technology.

- Fabric engineering is playing a crucial role in the development of innovative materials.

- Textile engineering is driving sustainability in the industry.

- The future of textiles looks promising with the integration of technology and engineering.

- Textile innovation is expected to have a significant impact on various industries.

The Evolution of Textile Engineering

The history of textile engineering is a rich tapestry that weaves together ancient techniques and modern innovations. This field has undergone significant transformations over the centuries, driven by technological advancements and changing societal needs.

From Ancient Weaving to Modern Technology

Ancient civilizations laid the foundation for modern textile engineering. The earliest evidence of textile production dates back to around 5000 BC, with the use of simple looms and natural fibers. As civilizations evolved, so did their textile technologies. For instance, the ancient Egyptians developed advanced dyeing techniques, while the Chinese mastered sericulture, the cultivation of silk.

Key Historical Milestones in Textile Development

The Industrial Revolution marked a significant turning point in textile engineering history, with the introduction of mechanized spinning and weaving machines. This period saw the development of factories and mass production techniques, revolutionizing the textile industry.

| Period | Major Developments |

|---|---|

| Pre-Industrial | Handloom weaving, natural dyeing |

| Industrial Revolution | Mechanized spinning, power looms |

| 20th Century | Synthetic fibers, computer-aided design |

The evolution of textile engineering continues to this day, with advancements in modern textile technology, including the development of high-performance fibers and digital printing techniques. Understanding the history and milestones of textile development provides valuable insights into the complex and dynamic nature of this field.

Fundamentals of Textile Engineering

Textile engineering is built on a foundation of core principles that integrate materials science, mechanical engineering, and other disciplines. This interdisciplinary field combines theoretical knowledge with practical application to create innovative textile solutions.

Core Principles and Scientific Foundations

The core principles of textile engineering include understanding the properties and behavior of various textile materials. This involves studying the structure, processing, and performance of fibers, yarns, and fabrics. Materials science plays a crucial role in this aspect, as it helps engineers develop new materials with specific properties.

The Interdisciplinary Nature of Textile Science

Textile science is inherently interdisciplinary, drawing on knowledge from materials science, engineering mechanics, chemistry, and physics. This integration enables textile engineers to design and develop complex fabric structures with desired properties.

Materials Science in Textiles

Materials science is fundamental to textile engineering, as it involves the study of the properties and applications of various textile materials. This includes understanding the chemical composition, physical structure, and mechanical properties of fibers and fabrics.

Engineering Mechanics in Fabric Structures

Engineering mechanics is essential for understanding the behavior of fabric structures under different conditions. It involves analyzing the mechanical properties of textiles, such as tensile strength, elasticity, and durability, to predict their performance in various applications.

The integration of engineering mechanics and materials science in textile engineering enables the development of high-performance textiles for a wide range of applications, from clothing and upholstery to technical textiles used in industrial and medical contexts.

Fiber Science: The Building Blocks of Textiles

Understanding fiber science is crucial for advancing textile technology and developing innovative materials. Fiber science encompasses the study of both natural and synthetic fibers, their properties, and how they are engineered to create various textiles.

Natural Fibers and Their Unique Properties

Natural fibers, such as cotton, wool, and silk, have been used for centuries in textile production. Each of these fibers has unique properties that make them suitable for different applications. For instance, cotton is breathable and absorbent, making it ideal for casual wear. Wool, on the other hand, provides excellent insulation and is often used in cold-weather clothing.

Key properties of natural fibers include:

- Breathability

- Durability

- Biodegradability

Synthetic Fibers and Their Development

Synthetic fibers, such as nylon, polyester, and spandex, have revolutionized the textile industry with their versatility and performance. These fibers are engineered to have specific properties, such as elasticity, strength, and resistance to chemicals.

| Fiber Type | Key Properties | Common Uses |

|---|---|---|

| Cotton (Natural) | Breathable, absorbent | Casual wear, bedding |

| Polyester (Synthetic) | Durable, wrinkle-resistant | Outdoor gear, activewear |

| Nylon (Synthetic) | Strong, elastic | Hosiery, sportswear |

Advanced Fiber Engineering Techniques

Fiber engineering has advanced significantly, allowing for the development of fibers with tailored properties. One such advancement is nanofiber technology.

Nanofiber Technology

Nanofiber technology involves creating fibers with diameters in the nanometer range. These fibers have unique properties, such as high surface area and strength, making them suitable for applications in filtration, medical textiles, and energy storage.

The future of textiles lies in continuing to innovate and engineer fibers that meet specific needs, whether for performance, sustainability, or functionality.

Textile Manufacturing Processes

Textile manufacturing encompasses a broad range of processes, from spinning and yarn production to weaving and knitting. These processes are crucial in transforming raw fibers into finished fabrics that meet various end-use requirements.

Spinning and Yarn Production Technologies

Spinning is the process of creating yarn from fibers. Modern spinning technologies have significantly improved the quality and consistency of yarns. Ring spinning and rotor spinning are two dominant methods used in the industry. Ring spinning produces high-quality yarns with excellent strength and fineness, while rotor spinning is known for its high production rates and cost-effectiveness.

| Spinning Method | Yarn Characteristics | Production Rate |

|---|---|---|

| Ring Spinning | High strength, fine yarn | Moderate |

| Rotor Spinning | Good uniformity, suitable for medium to coarse counts | High |

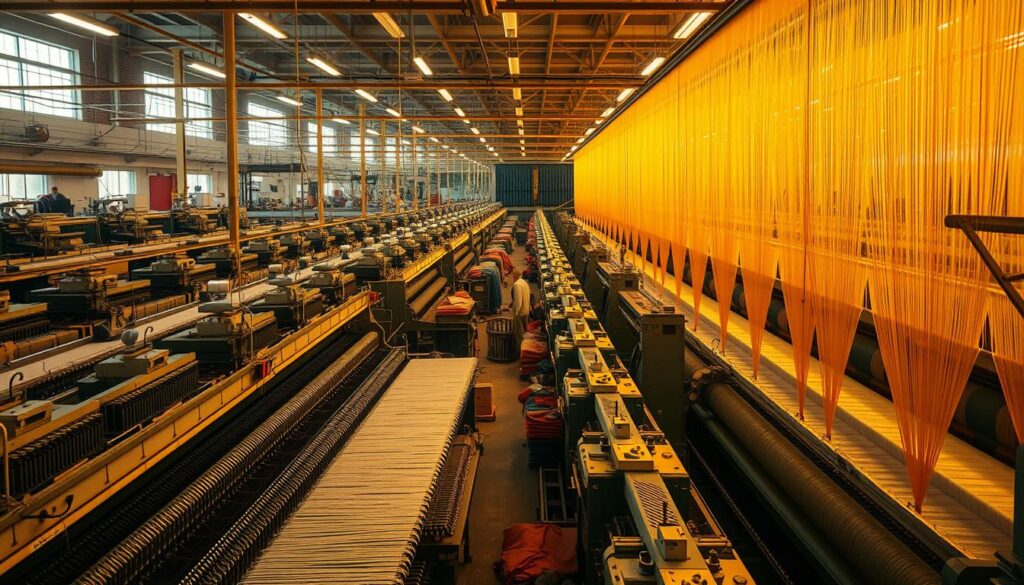

Modern Weaving Techniques

Weaving is a traditional method of fabric production that involves interlacing two sets of yarns at right angles. Modern weaving techniques have evolved to include advanced loom technologies such as rapier looms and air-jet looms. These looms offer higher productivity and the ability to weave complex patterns and designs.

Knitting and Non-woven Production Methods

Knitting involves creating fabric by interlooping yarns. Modern knitting machines can produce a wide range of fabrics, from simple jerseys to complex double-knit fabrics. Non-woven production, on the other hand, involves bonding or felting fibers together without the need for yarn production. Techniques such as needle-punching and thermal bonding are commonly used.

3D Weaving and Knitting Innovations

Recent innovations in textile manufacturing include 3D weaving and knitting, which enable the production of complex, three-dimensional structures in a single step. These technologies have opened up new possibilities for the production of technical textiles, including composites for aerospace and biomedical applications.

Textile Machinery and Automation

The integration of automation and computer-aided manufacturing has transformed the textile industry’s landscape. This shift has not only enhanced production efficiency but also improved product quality and reduced labor costs.

Evolution of Textile Equipment

The evolution of textile machinery has been a gradual process, from manual looms to sophisticated computer-controlled equipment. Modern textile machinery incorporates advanced technologies such as automation and precision engineering to produce high-quality fabrics.

- Improved production speed and efficiency

- Enhanced product quality through precision control

- Reduced labor costs due to automation

Computer-Aided Manufacturing in Textiles

Computer-aided manufacturing (CAM) has revolutionized the textile industry by enabling precise control over manufacturing processes. CAM systems allow for the creation of complex patterns and designs with ease, improving product customization.

Key benefits of CAM in textiles include:

- Increased design flexibility

- Improved product consistency

- Reduced material waste

Industry 4.0 in Textile Production

Industry 4.0, also known as the Fourth Industrial Revolution, is transforming textile production through the integration of cyber-physical systems, the Internet of Things (IoT), and artificial intelligence (AI). This digital transformation enables real-time monitoring and optimization of production processes.

Robotics in Textile Manufacturing

Robotics plays a crucial role in modern textile manufacturing, performing tasks such as material handling, cutting, and sewing. Robotic systems enhance precision, speed, and flexibility in production, contributing to improved product quality and reduced costs.

The future of textile machinery and automation looks promising, with ongoing advancements in technologies like AI and IoT expected to further revolutionize the industry.

Textile Chemistry and Finishing

Textile chemistry encompasses a broad range of processes, including dyeing, printing, and finishing, which are crucial for achieving the desired properties and performance in textiles.

Advanced Dyeing Technologies

Modern dyeing technologies have significantly improved the efficiency and sustainability of textile production. Techniques such as continuous dyeing and low-water dyeing reduce environmental impact while maintaining high-quality coloration.

Digital Printing Techniques

Digital printing has revolutionized the textile industry by enabling rapid, high-resolution printing with minimal waste. This technology allows for on-demand production and complex designs that were previously unachievable.

Functional Finishing Processes

Functional finishing processes enhance the performance of textiles beyond aesthetics. These treatments can impart properties such as water repellency, flame retardancy, and soil resistance.

Antimicrobial and Performance Treatments

Antimicrobial treatments are increasingly important in various textile applications, including medical textiles and activewear. These treatments help prevent the growth of bacteria and odor-causing microorganisms, enhancing the durability and hygiene of the fabric.

Performance treatments, such as those improving breathability and moisture-wicking capabilities, are also critical in sportswear and outdoor apparel. These treatments ensure that garments perform well under various conditions, providing comfort and functionality to the wearer.

Technical Textiles: Engineering for Specialized Applications

Technical textiles are engineered materials designed for specific uses beyond traditional clothing. These advanced materials have transformed numerous industries, providing innovative solutions to complex challenges.

Medical and Healthcare Textiles

Medical textiles have become crucial in healthcare, offering a range of applications from implantable devices to wound care products. These textiles are designed to be biocompatible and durable, meeting the stringent requirements of medical environments.

- Implantable fabrics for surgical procedures

- Advanced wound dressings with antimicrobial properties

- Medical gowns and drapes for infection control

Geotextiles and Construction Applications

Geotextiles play a vital role in civil engineering and construction projects. They are used for soil stabilization, erosion control, and drainage systems, enhancing the durability and safety of infrastructure.

Key applications include:

- Road construction and reinforcement

- Erosion control measures

- Drainage systems for water management

Protective and Military Textile Applications

Protective textiles are designed to safeguard individuals in hazardous environments. Military textiles, in particular, have seen significant advancements, providing soldiers with enhanced protection and functionality.

Examples of protective textiles include:

- Ballistic vests and helmets

- Fire-resistant clothing for firefighters

- Chemical protective suits

Aerospace and Automotive Textiles

The aerospace and automotive industries also benefit from technical textiles, utilizing them for their strength, durability, and lightweight properties. In aerospace, these materials are used in aircraft components and insulation, while in automotive, they are found in tire reinforcements, airbags, and interior components.

Smart Textiles and Wearable Technology

The world of textiles is witnessing a paradigm shift with the advent of smart textiles and wearable technology. This fusion of technology and fabric is opening new avenues for various applications, from healthcare to sports and fashion.

E-textiles and Conductive Fabrics

E-textiles, or electronic textiles, integrate electronics into fabrics, enabling the creation of wearable devices that are both comfortable and functional. Conductive fabrics play a crucial role in this technology, allowing for the transmission of electrical signals through the textile. These fabrics are made using various techniques, including weaving conductive yarns, coating fabrics with conductive materials, or printing conductive patterns onto the fabric.

Sensor-Integrated Textiles

Sensor-integrated textiles are another significant development in smart textiles. These textiles incorporate sensors that can monitor various physiological parameters, such as heart rate, body temperature, and muscle activity. The data collected can be used for health monitoring, fitness tracking, or even for athletes to optimize their performance.

Human-Centered Design in Smart Textiles

Human-centered design is crucial in the development of smart textiles. It involves creating products that are not only technologically advanced but also comfortable, intuitive, and user-friendly. Designers must consider factors such as wearability, aesthetics, and the user’s interaction with the textile.

Energy Harvesting Textiles

Energy harvesting textiles represent a cutting-edge area of research, focusing on generating power from the wearer’s movements or environmental factors like sunlight or temperature changes. This technology has the potential to power wearable devices, reducing the need for batteries and enhancing the sustainability of smart textiles.

| Technology | Description | Application |

|---|---|---|

| E-textiles | Integration of electronics into fabrics | Wearable devices, health monitoring |

| Conductive Fabrics | Fabrics that conduct electrical signals | Smart clothing, wearable technology |

| Sensor-Integrated Textiles | Textiles with integrated sensors for monitoring physiological parameters | Health monitoring, fitness tracking |

The development of smart textiles and wearable technology is a rapidly evolving field, with significant potential to impact various aspects of our lives. As technology continues to advance, we can expect to see more innovative applications of smart textiles in the future.

Sustainable Practices in Textile Engineering

The textile industry is shifting towards sustainability, driven by eco-friendly innovations. As consumers become more environmentally conscious, manufacturers are adapting to meet the demand for greener products.

Eco-friendly Fiber Production

The production of eco-friendly fibers is a crucial step towards sustainable textiles. This involves using natural fibers, such as organic cotton and hemp, which have a lower environmental impact compared to conventional cotton. Organic farming practices reduce the use of harmful pesticides and fertilizers, promoting biodiversity and soil health.

Additionally, the development of recycled fibers from post-consumer waste is gaining traction. These fibers reduce the need for virgin materials and help decrease textile waste.

Reducing Environmental Impact in Manufacturing

Manufacturing processes in the textile industry have a significant environmental footprint. To mitigate this, companies are adopting cleaner production techniques, such as using renewable energy sources and implementing water-saving technologies. Efficient dyeing and finishing processes also play a crucial role in reducing chemical usage and waste.

Circular Economy Approaches in Textiles

The circular economy model is being increasingly adopted in the textile industry. This approach encourages the reuse and recycling of materials, minimizing waste and the continuous consumption of resources. Designing products for recyclability and using modular designs are key strategies in this approach.

Biodegradable and Compostable Textile Solutions

Biodegradable and compostable textiles offer a promising solution to the environmental challenges faced by the industry. These materials can decompose naturally, reducing landfill waste and the environmental harm caused by synthetic textiles. Innovations in biodegradable polymers and natural fiber composites are paving the way for more sustainable textile products.

By embracing sustainable practices, the textile industry can significantly reduce its environmental impact. As technology advances and consumer awareness grows, the shift towards a more sustainable and circular textile industry is expected to continue.

Quality Control and Testing in Textile Engineering

Quality control plays a crucial role in textile engineering, impacting both performance and safety. The textile industry relies on various testing methods and quality assurance technologies to ensure that fabrics meet the required standards.

Standard Testing Methods and Protocols

Standard testing methods are essential for evaluating the quality and performance of textiles. These methods include:

- Physical tests such as tensile strength and tear resistance

- Chemical tests to determine fabric composition and detect contaminants

- Colorfastness tests to assess the durability of dyes and prints

These tests are conducted using specialized equipment and follow international standards such as ISO and ASTM.

Advanced Quality Assurance Technologies

The textile industry has seen significant advancements in quality assurance technologies. Some of these include:

- Computer vision systems for automated defect detection

- Online monitoring systems to track production parameters in real-time

- Statistical process control to identify and correct deviations in the manufacturing process

These technologies help in improving the efficiency and accuracy of quality control processes.

Ensuring Textile Performance and Safety

Ensuring the performance and safety of textiles is paramount. This involves not only testing for physical and chemical properties but also evaluating the textile’s suitability for its intended application.

Artificial Intelligence in Quality Control

Artificial intelligence (AI) is increasingly being used in textile quality control. AI algorithms can analyze data from various sources to predict potential defects and optimize the manufacturing process. For instance, AI-powered computer vision can detect even the smallest defects in fabrics, improving overall quality.

The integration of AI in quality control represents a significant step forward in textile engineering, enabling manufacturers to produce higher quality textiles while reducing waste and improving efficiency.

Textile Design and Product Development

The realm of textile engineering is significantly influenced by textile design and product development, which play pivotal roles in shaping the future of textiles. This crucial aspect of the industry combines creativity, technology, and practical considerations to produce innovative textile products.

Computer-Aided Design in Modern Textiles

Computer-aided design (CAD) has revolutionized the textile industry by enabling designers to create complex patterns and designs with precision and speed. CAD software allows for the simulation of various textile effects, reducing the need for physical prototypes and accelerating the design process.

According to a report by the Textile and Fashion Federation, the adoption of CAD technology has led to a significant reduction in design-to-production time, improving overall efficiency.

Innovative Approaches to Fabric Design

Innovative approaches to fabric design are driven by both aesthetic considerations and functional requirements. Techniques such as digital printing and 3D weaving are being used to create unique and complex fabric structures.

“The integration of technology in textile design has opened up new avenues for creativity and innovation, enabling designers to push the boundaries of what is possible.”

From Concept to Commercial Product

The journey from concept to commercial product involves several stages, including design development, prototyping, and testing. Collaborative design processes are essential in this phase, as they bring together designers, engineers, and manufacturers to ensure that the final product meets both aesthetic and functional requirements.

Collaborative Design Processes

Effective collaboration in textile design involves the use of shared digital platforms and regular communication among team members. This collaborative approach ensures that all stakeholders are aligned throughout the product development process.

| Stage | Description | Key Activities |

|---|---|---|

| Design Development | Creation of initial designs | Sketching, CAD design |

| Prototyping | Production of sample products | Material selection, sampling |

| Testing | Evaluation of product performance | Quality control, performance testing |

By embracing computer-aided design and collaborative design processes, the textile industry can continue to innovate and produce high-quality, functional, and aesthetically pleasing products.

The Global Textile Industry: Trends and Challenges

The global textile industry is navigating a complex landscape of trends and challenges. As a significant contributor to the world economy, the industry is influenced by various factors including market dynamics, economic conditions, and regional manufacturing capabilities.

Market Dynamics and Economic Factors

The global textile industry is subject to fluctuating market dynamics and economic factors. Global demand and supply chains play a crucial role in shaping the industry. Economic factors such as labor costs, raw material prices, and currency exchange rates significantly impact production costs and profitability.

Regional Manufacturing Hubs and Specializations

Different regions have emerged as significant manufacturing hubs due to their unique advantages. For instance, Asia has become a dominant player due to its large workforce and established supply chains. In contrast, regions like Europe and North America are focusing on high-value and technical textiles.

Navigating Trade Policies and Regulations

Trade policies and regulations pose both challenges and opportunities for the global textile industry. Tariffs, quotas, and other trade barriers can affect the competitiveness of textile manufacturers. Understanding and adapting to these regulations is crucial for businesses to remain competitive.

Reshoring and Nearshoring Trends

The trends of reshoring and nearshoring are gaining traction as companies look to diversify their supply chains and reduce dependency on distant manufacturing hubs. Reshoring involves bringing production back to the home country, while nearshoring refers to relocating production to nearby countries. These strategies can offer advantages in terms of reduced lead times and improved quality control.

Careers and Education in Textile Engineering

As the textile industry continues to grow, the demand for skilled engineers who can innovate and optimize production processes increases. This growth is driven by advancements in technology and the need for sustainable and high-performance materials.

Educational Pathways and Specializations

Textile engineering education typically involves a combination of theoretical foundations and practical training. Students can pursue degrees in textile engineering or related fields such as materials science, mechanical engineering, or chemistry. Specializations within textile engineering programs may include fiber science, textile manufacturing, and textile chemistry.

Many institutions offer undergraduate and graduate programs that cater to the diverse needs of the textile industry. These programs often include coursework in textile technology, materials science, and engineering principles. Hands-on experience through internships and research projects is also a crucial component of textile engineering education.

Job Opportunities Across the Textile Value Chain

Textile engineers can find employment across various sectors of the textile industry, from fiber production to fabric finishing. Job roles may include process engineer, quality control manager, research and development specialist, and production manager. The versatility of textile engineering education allows graduates to work in diverse environments, from manufacturing plants to research institutions.

| Job Role | Primary Responsibilities | Industry Sector |

|---|---|---|

| Process Engineer | Optimize manufacturing processes, improve efficiency | Manufacturing |

| Quality Control Manager | Ensure product quality, implement quality control measures | Manufacturing, R&D |

| R&D Specialist | Develop new textile materials and products | R&D, Manufacturing |

Skills Needed for Future Textile Engineers

Future textile engineers will need to possess a blend of technical skills, creativity, and problem-solving abilities. Key skills include knowledge of textile technology, materials science, and engineering principles. Additionally, soft skills such as communication, teamwork, and adaptability are crucial in this field.

Continuing Education and Professional Development

The rapidly evolving nature of the textile industry necessitates ongoing education and professional development for textile engineers. Continuing education programs, workshops, and conferences provide opportunities for professionals to stay updated on the latest technologies and trends. Many companies also invest in employee training programs to enhance their workforce’s skills and knowledge.

Conclusion: The Fabric of Our Future

The textile industry is on the cusp of a revolution, driven by advancements in textile engineering and a growing focus on sustainability. As we’ve explored throughout this article, innovations in fiber science, manufacturing processes, and textile chemistry are transforming the way we produce and interact with textiles.

The future of textiles is closely tied to the development of sustainable practices, from eco-friendly fiber production to circular economy approaches in manufacturing. Textile engineering advancements are enabling the creation of high-performance, functional fabrics that not only meet consumer demands but also contribute to a more environmentally conscious industry.

As we look ahead, it’s clear that textile innovation will play a critical role in shaping the industry’s future. By embracing new technologies, sustainable materials, and innovative manufacturing processes, the textile sector can continue to evolve and thrive. The fabric of our future is being woven today, with a focus on quality, sustainability, and performance.