When it comes to railway operations, having reliable railroad supplies is crucial for ensuring safe and efficient transportation. The quality of train track equipment and other railway components directly impacts the overall performance of the railway system.

Using high-quality railroad construction materials is essential for maintaining the integrity of the railway infrastructure. This not only enhances the safety of passengers and cargo but also reduces maintenance costs in the long run.

Key Takeaways

- Reliable railway materials are crucial for safe and efficient railway operations.

- High-quality train track equipment enhances overall railway performance.

- Using superior railroad construction materials reduces maintenance costs.

- Railway components play a vital role in ensuring the integrity of the railway infrastructure.

- Investing in quality railroad supplies is essential for long-term efficiency.

The Critical Role of Quality Railway Materials in Modern Transportation

Quality railway materials play a pivotal role in ensuring the safety, efficiency, and reliability of modern rail transportation. The use of superior materials in railway construction and maintenance is crucial for withstanding the demands of heavy usage and harsh environmental conditions.

Safety and Performance Dependencies

The safety of railway operations is heavily dependent on the quality of materials used. Track maintenance supplies and train track materials that meet stringent standards are essential for preventing accidents and ensuring smooth operations. High-quality materials reduce the risk of derailments and other safety incidents.

The performance of railway systems is also directly influenced by the materials used. For instance, the durability and resistance of railway construction materials affect the frequency of maintenance needs and the overall lifespan of the infrastructure.

| Material Type | Safety Impact | Performance Impact |

|---|---|---|

| Railway Tracks | High | High |

| Switches and Crossings | High | Medium |

| Ballast and Sub-ballast | Medium | High |

Economic Impact of Material Selection

The economic implications of choosing the right train infrastructure materials and rail yard supplies are significant. While high-quality materials may have a higher upfront cost, they offer long-term savings through reduced maintenance needs and extended lifespan.

A well-planned material selection strategy can lead to substantial cost savings over the lifecycle of railway infrastructure. This includes minimizing the need for frequent repairs and replacements, thereby reducing operational disruptions.

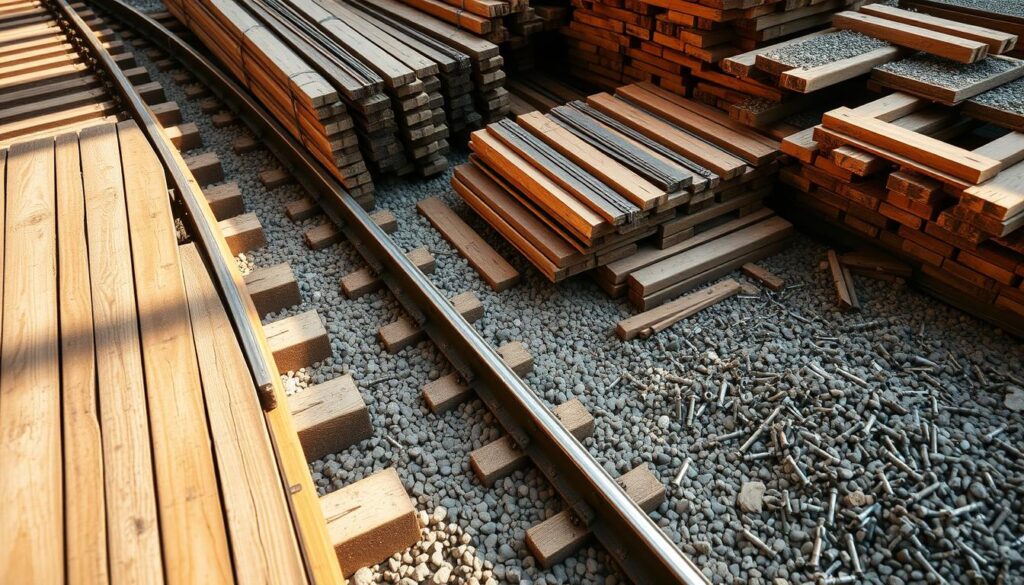

Essential Railway Track Components for Reliable Infrastructure

Reliable railway infrastructure is built on several essential track components. These components work together to ensure the safe and efficient transportation of passengers and freight.

Rails and Rail Profiles

Rails are a critical component of railway tracks, providing a smooth surface for train wheels. Different rail profiles are used depending on the specific application and load requirements.

Standard Rail Types Used in American Railways

American railways commonly use rail types such as 115 RE and 136 RE, which are specified by the American Railway Engineering and Maintenance-of-Way Association (AREMA). These rails are designed to withstand heavy loads and provide a durable riding surface.

Wear-Resistant Rail Technologies

To extend the life of rails, wear-resistant technologies are employed, including head-hardened rails and rails with advanced alloy compositions. These technologies help reduce maintenance costs and improve overall safety.

Sleepers and Ties: Wood, Concrete, and Composite Options

Sleepers, also known as ties, are another vital component of railway tracks. They are available in various materials, including wood, concrete, and composite materials, each with its own advantages and disadvantages.

For instance, a study comparing different sleeper materials found that composite sleepers offer a good balance between durability and environmental sustainability.

| Material | Durability | Environmental Impact |

|---|---|---|

| Wood | Medium | High |

| Concrete | High | Medium |

| Composite | High | Low |

Fastening Systems and Clip Assemblies

Fastening systems and clip assemblies are crucial for securing rails to sleepers. They must be designed to withstand various environmental conditions and heavy loads.

According to industry experts, “The choice of fastening system can significantly impact the overall performance and maintenance requirements of the railway track.”

“The selection of the appropriate fastening system is critical to ensuring the stability and longevity of the railway track.”

Modern fastening systems are designed to be highly reliable and require minimal maintenance.

Track Ballast and Foundation Materials for Stability

Track ballast and foundation materials play a crucial role in maintaining railway track stability. The right track construction materials are essential for ensuring the longevity and safety of railway infrastructure.

The selection of appropriate ballast materials is critical for drainage, load distribution, and track alignment. Crushed stone and granite are popular choices for ballast due to their durability and resistance to weathering.

Crushed Stone and Granite Ballast Options

Crushed stone is widely used as a ballast material due to its angular shape, which provides excellent interlocking properties. Granite ballast, on the other hand, offers superior hardness and resistance to abrasion, making it suitable for high-traffic rail lines. Both materials are effective track maintenance products that help maintain track geometry and stability.

Sub-Ballast and Formation Layers for American Rail Systems

Sub-ballast layers are crucial for distributing loads and preventing the contamination of ballast with fine particles from the subgrade. In American rail systems, the sub-ballast layer is typically composed of a mixture of aggregate materials. Proper design and construction of these layers are vital for the long-term performance of the railway track, involving careful selection of railway building materials.

Effective track maintenance also involves the use of appropriate track maintenance equipment to ensure that the track remains in good condition.

Railway Switches and Crossings: Critical Junction Materials

The integrity of railway switches and crossings is vital for the overall safety and efficiency of rail transportation. These complex components are subject to high stress and wear, making the selection of appropriate materials crucial. Railway switches enable trains to change tracks, while crossings allow tracks to intersect, both requiring precise engineering and high-quality train components.

Switch Components and High-Stress Materials

Switch components, including switch rails, stock rails, and switch points, are made from high-strength materials to withstand the constant stress of train passage. The use of high-manganese steel is common due to its durability and resistance to wear. Additionally, the application of railway fasteners ensures that the switch components remain securely in place, maintaining the integrity of the railway infrastructure.

Diamond Crossing Design and Manganese Steel Applications

Diamond crossings are intricate components that allow for the intersection of two tracks. The design of these crossings involves complex geometry and the use of manganese steel for its high durability and ability to withstand heavy loads. The application of manganese steel in diamond crossings reduces the need for frequent maintenance, ensuring the reliability of locomotive parts and overall railway infrastructure. Properly designed and maintained crossings are essential for safe and efficient rail operations.

Comprehensive Railway Material Solutions for Complete Projects

Comprehensive railway material solutions are crucial for the successful completion of railway projects. These solutions encompass a wide range of materials and equipment necessary for constructing and maintaining railway infrastructure.

One-Stop Shopping for Railway Construction

One of the key benefits of comprehensive railway material solutions is the convenience of one-stop shopping for railway construction. This approach allows contractors and project managers to source all necessary materials from a single supplier, simplifying logistics and reducing project timelines.

Suppliers offering comprehensive solutions typically provide a broad range of products, including railroad components, train track supplies, and railway maintenance equipment. This one-stop shopping experience can significantly streamline the procurement process, ensuring that all materials are compatible and meet project specifications.

Integrated Material Systems and Compatibility

Another critical aspect of comprehensive railway material solutions is the focus on integrated material systems and compatibility. Railway projects require a complex interplay of various components, from rails and sleepers to signaling systems and fastening hardware.

“The key to a successful railway project lies in the compatibility and integration of its various components. By sourcing materials from a single, reputable supplier, project managers can ensure that all elements work together seamlessly.”

A well-integrated material system can improve the overall performance and longevity of the railway infrastructure. For instance, using rail welding kits from a reputable manufacturer can ensure strong, durable joints in the rail network.

| Material/System | Description | Benefits |

|---|---|---|

| Rail Welding Kits | Equipment for welding rails into continuous lengths | Improved ride quality, reduced maintenance |

| Railroad Components | Rails, sleepers, fastening systems | Structural integrity, safety |

| Train Track Supplies | Ballast, sub-ballast, and other track materials | Stability, drainage, and load distribution |

By focusing on comprehensive railway material solutions, project managers can ensure that their railway projects are completed on time, within budget, and to the required quality standards.

Signaling System Components and Materials

Signaling systems are crucial for the safe and efficient operation of rail networks, relying on various components and materials. These systems are designed to prevent accidents and ensure smooth train operations by providing critical information to drivers and control centers.

Track Circuits and Detection Systems

Track circuits and detection systems are fundamental components of railway signaling. They detect the presence of trains on specific sections of track, preventing collisions and enabling efficient train control. Modern track circuits use advanced technologies, including audio frequency track circuits, to provide reliable detection.

Signal Lights and Control Equipment

Signal lights are a critical aspect of railway signaling, conveying vital information to train drivers about whether they can proceed or must stop. Modern signal lights use LED technology for improved visibility and reduced maintenance. Control equipment, including interlocking systems, manage signal operations, ensuring that signals are correctly set based on track occupancy and other factors.

Weather-Resistant Cable and Wiring Materials

The reliability of railway signaling systems depends on the quality of their cabling and wiring. Weather-resistant materials are essential for withstanding the harsh conditions often encountered in outdoor railway environments. These materials help prevent signal degradation and ensure continuous operation.

| Component | Material | Benefit |

|---|---|---|

| Track Circuits | Audio Frequency Technology | Reliable Detection |

| Signal Lights | LED Technology | Improved Visibility, Reduced Maintenance |

| Cabling and Wiring | Weather-Resistant Materials | Signal Integrity, Durability |

Effective signaling systems are crucial for the safe and efficient operation of rail networks. By utilizing high-quality components and materials, such as advanced track circuits, LED signal lights, and weather-resistant cabling, rail operators can ensure reliable train control and minimize the risk of accidents.

American Railway Material Standards and Specifications

The railway industry in America adheres to rigorous standards for materials used in trackwork supplies and railroad track components. Ensuring the reliability of railway equipment and track materials is paramount for safety and efficiency.

These standards are crucial for maintaining the integrity of railway infrastructure. The primary organizations responsible for governing these standards are the American Railway Engineering and Maintenance-of-Way Association (AREMA) and the Federal Railroad Administration (FRA).

AREMA Standards and Compliance Requirements

AREMA standards provide comprehensive guidelines for railroad track components and track materials. Compliance with these standards is essential for ensuring the structural integrity and safety of railway tracks. Key areas covered by AREMA standards include:

- Rail and rail profiles

- Sleepers and ties

- Fastening systems

FRA Regulations for Material Quality and Testing

The FRA enforces regulations that govern the quality and testing of railway equipment and materials. These regulations are designed to ensure that all train track components meet stringent safety standards. The FRA’s regulations cover various aspects, including material specifications and testing protocols.

By adhering to these standards and regulations, the railway industry can maintain high levels of safety and performance. It’s crucial for suppliers and manufacturers of trackwork supplies to comply with these requirements to ensure the reliability of railway infrastructure.

Locomotive Components and Specialized Materials

Locomotives are complex machines that rely on a variety of specialized materials for their components. The efficiency, safety, and reliability of locomotives depend on the quality and performance of these materials.

Engine and Power System Materials

The engine and power system of a locomotive require materials that can withstand high temperatures and stresses. Advanced materials like high-strength steel alloys and ceramics are used to enhance performance and durability. These materials are crucial for the longevity of the locomotive’s engine and power system.

Braking System Components and Friction Materials

The braking system is another critical component of a locomotive, relying on friction materials that can provide consistent and reliable stopping power. Materials such as copper-free brake shoes and advanced composites are used to ensure effective braking under various conditions.

Locomotive Frame and Structural Materials

The frame and structural components of a locomotive are typically made from high-strength steel to provide the necessary strength and durability. These materials are designed to withstand the stresses of operation and ensure the overall integrity of the locomotive.

By utilizing advanced and specialized materials, locomotive manufacturers can produce more efficient, reliable, and safe locomotives, contributing to the overall performance of railway infrastructure.

Rolling Stock Materials for Passenger and Freight Applications

With the increasing demand for railway transportation, the importance of high-quality rolling stock materials cannot be overstated. The durability and performance of railway vehicles depend significantly on the materials used in their construction.

The selection of materials for rolling stock involves considering factors such as strength, durability, and resistance to wear and tear. For instance, aluminum and stainless steel are commonly used in the manufacture of passenger cars due to their lightweight and corrosion-resistant properties.

Passenger Car Materials and Interior Components

Passenger car materials are chosen for their ability to provide comfort and safety while minimizing weight to enhance energy efficiency. Interior components such as seating, flooring, and wall panels are made from materials that are not only durable but also aesthetically pleasing.

For example, advanced composites are used in some modern passenger trains to reduce weight while maintaining structural integrity. The use of such materials contributes to improved fuel efficiency and reduced maintenance costs.

| Material | Application | Benefits |

|---|---|---|

| Aluminum | Car body | Lightweight, corrosion-resistant |

| Stainless Steel | Structural components | High strength, durability |

| Advanced Composites | Interior panels | Lightweight, customizable |

Freight Car Components and Heavy-Duty Materials

Freight cars, on the other hand, require materials that can withstand heavy loads and harsh operating conditions. High-strength steel is often used in the construction of freight cars due to its ability to support heavy payloads.

Components such as wheelsets and couplers are made from robust materials to ensure reliable operation. The use of heavy-duty materials in freight car construction is critical for maintaining the safety and efficiency of freight operations.

Track Maintenance Tools and Equipment

Maintaining railway tracks requires a diverse set of tools and machinery, from digital inspection tools to heavy maintenance equipment. The rail industry relies on these rail industry supplies to ensure the safety and efficiency of railway operations.

Digital Track Inspection Tools

Digital track inspection tools have revolutionized the way railways are maintained. These tools use advanced technology to detect defects and irregularities in the tracks, allowing for precise maintenance planning. They are a crucial part of modern railway infrastructure products, enhancing safety and reducing downtime.

Heavy Maintenance Machinery and Equipment

Heavy machinery is essential for large-scale maintenance tasks, such as replacing rails or repairing switches. This machinery includes tampers, ballast regulators, and rail saws, all of which are vital locomotive equipment and track accessories that facilitate efficient maintenance operations.

Specialized Hand Tools for Railway Maintenance

While heavy machinery handles large tasks, specialized hand tools are used for more precise work. These include rail tongs, spike mauls, and measuring gauges, which are indispensable for daily maintenance tasks. They are part of the broader category of train equipment that ensures the railway network remains operational.

| Tool/Equipment | Description | Application |

|---|---|---|

| Digital Track Inspection Tools | Advanced technology for detecting track defects | Precision maintenance planning |

| Tampers | Heavy machinery for stabilizing tracks | Large-scale maintenance |

| Rail Tongs | Hand tool for handling rails | Daily maintenance tasks |

Railway Construction Materials for New Infrastructure Projects

New railway infrastructure projects rely heavily on the right construction materials to meet modern transportation needs. The selection of these materials is crucial for ensuring the durability, safety, and efficiency of the railway network.

Material Requirements Planning and Logistics

Effective material requirements planning is essential for the timely completion of railway construction projects. This involves identifying the necessary railway infrastructure components, such as rail track components and rail fasteners, and ensuring their availability. Logistics play a critical role in delivering these materials to the construction site, minimizing delays and reducing costs.

Environmental Considerations in Material Selection

The selection of materials for railway construction must consider environmental impact. This includes choosing materials that are sustainable, recyclable, and have a minimal carbon footprint. Eco-friendly rail fasteners and other components are becoming increasingly popular as the industry moves towards more sustainable practices.

Construction Equipment and Temporary Support Materials

Railway construction requires specialized equipment and temporary support materials. Railroad equipment such as cranes, excavators, and rail laying machines are essential for the construction process. Temporary support materials, including temporary rail tracks and support structures, are used to facilitate the construction of permanent train tracks.

The successful completion of new railway infrastructure projects depends on the careful planning and execution of material procurement, logistics, and construction processes. By focusing on the right materials and practices, the railway industry can build a more sustainable and efficient network.

Specialized Railway Material for American Climate Zones

The diverse climate zones across America necessitate specialized railway materials to ensure safe and efficient rail operations. From the freezing winters of the north to the sweltering summers of the south, railway infrastructure must withstand a wide range of environmental conditions.

Cold Weather Railway Solutions for Northern States

In the northern United States, railway materials must be capable of withstanding extremely low temperatures and icy conditions. Specialized steel alloys and advanced composites are used to maintain the integrity of rails and other critical components. These materials help prevent brittle fracture and ensure that railway infrastructure remains operational during harsh winter conditions.

| Material | Characteristics | Benefits |

|---|---|---|

| Specialized Steel Alloys | High strength, low temperature resistance | Prevents brittle fracture, maintains rail integrity |

| Advanced Composites | High durability, resistance to corrosion | Reduces maintenance needs, extends lifespan |

Heat-Resistant Track Materials for Southern Regions

In contrast, the southern regions of the United States require railway materials that can withstand high temperatures and intense sunlight. Heat-resistant coatings and specialized elastomers are used to protect rails and fastening systems from degradation caused by extreme heat. These materials help maintain the stability and safety of railway operations during the hot summer months.

| Material | Characteristics | Benefits |

|---|---|---|

| Heat-Resistant Coatings | High temperature resistance, durability | Protects rails from heat damage, reduces maintenance |

| Specialized Elastomers | High temperature stability, resistance to degradation | Maintains fastening system integrity, ensures safe operations |

Railway Infrastructure Materials for Bridges and Tunnels

Bridges and tunnels are critical components of railway infrastructure, necessitating the use of robust and reliable materials. The selection of appropriate materials is crucial for ensuring the safety, durability, and performance of these structures.

Bridge Construction Materials and Structural Components

Bridge construction in railway infrastructure involves the use of high-strength materials such as steel and concrete. These materials are chosen for their ability to withstand heavy loads and harsh environmental conditions. The structural components of railway bridges include girders, bearings, and piers, which are designed to provide maximum stability and support.

The use of advanced materials like fiber-reinforced polymers (FRP) is becoming increasingly popular in bridge construction due to their high strength-to-weight ratio and resistance to corrosion. According to a report by the American Railway Engineering and Maintenance-of-Way Association (AREMA), the use of FRP can significantly extend the lifespan of railway bridges.

“The use of advanced composites in bridge construction has revolutionized the industry, offering improved durability and reduced maintenance costs.”

| Material | Characteristics | Applications |

|---|---|---|

| Steel | High strength, durability | Girders, piers |

| Concrete | High compressive strength, durability | Bridge decks, foundations |

| FRP | High strength-to-weight ratio, corrosion resistance | Bridge decks, structural reinforcement |

Tunnel Support Systems and Waterproofing Materials

Tunnel construction requires robust support systems to ensure stability and safety. Common materials used for tunnel support include steel ribs, shotcrete, and rock bolts. Waterproofing is also a critical aspect of tunnel construction, with materials like bentonite and PVC membranes being used to prevent water ingress.

- Steel ribs provide structural support and stability.

- Shotcrete is used for lining and reinforcing the tunnel walls.

- Rock bolts help to stabilize the rock mass around the tunnel.

The selection of appropriate materials for tunnel support and waterproofing is crucial for maintaining the integrity of the tunnel and ensuring the safety of railway operations.

Selecting the Right Railway Material Supplier for Your Project

When it comes to railway projects, the importance of selecting the right material supplier cannot be overstated. A reliable supplier can ensure that your project receives the highest quality rail transportation materials and locomotive maintenance supplies needed for successful completion.

Evaluating Supplier Credentials and Experience

To ensure that you’re working with a credible supplier, it’s essential to evaluate their credentials and experience in providing track infrastructure supplies. Look for suppliers who have a proven track record in the industry and can provide references or case studies that demonstrate their capabilities.

Quality Assurance Processes and Material Testing

A reliable supplier should have robust quality assurance processes in place, including rigorous material testing to ensure that their products meet the required standards. This is particularly important for rail accessories and other critical components that impact the safety and performance of railway systems.

Delivery Capabilities and Supply Chain Reliability

The ability of a supplier to deliver materials on time is crucial for maintaining project timelines. Assess the supplier’s delivery capabilities and their supply chain reliability, especially for complex rail infrastructure equipment. A supplier with a strong logistics network can help prevent delays and ensure that your project stays on track.

Cost Considerations and Value Analysis for Railway Materials

Effective railway material selection involves a delicate balance between initial costs and long-term value. When planning railway projects, it’s essential to consider not just the upfront expenses but also the lifecycle costs associated with the materials chosen.

Initial Investment vs. Lifecycle Cost Analysis

The initial investment in railway materials, such as train hardware supplies and railroad technology products, is a significant factor in project budgeting. However, a comprehensive lifecycle cost analysis can reveal the true value of these materials over time, including maintenance, replacement, and operational costs.

As noted by industry experts, “A thorough lifecycle cost analysis can help railway operators save millions of dollars in the long run by identifying the most cost-effective materials and maintenance strategies.”

Budgeting Strategies for Large-Scale Railway Projects

For large-scale railway projects, budgeting strategies must account for the scale and complexity of the infrastructure. This includes considering the costs of train infrastructure, rail equipment, and railway maintenance over the project’s lifespan.

By adopting a strategic approach to budgeting and cost analysis, railway project managers can ensure that their projects are financially sustainable and deliver long-term value.

Conclusion: Building a Sustainable Railway Future with Quality Materials

Quality railway materials play a vital role in building a sustainable railway future. Reliable locomotive supplies and railway components ensure the safety and performance of railway infrastructure.

Railway track accessories and railway infrastructure supplies are critical for reducing maintenance costs and extending asset lifespan. High-quality railroad track tools enable efficient track maintenance and repair.

A well-planned railway infrastructure, supported by quality materials, withstands modern transportation demands. Investing in reliable railway materials is essential for a more efficient, safe, and environmentally friendly transportation system.

The industry must prioritize quality and sustainability in railway material selection to achieve a sustainable railway future.