Core Components of Railway Bridge Structural Design

Successful railway bridge design relies on the careful integration of several critical structural components. Each element must be precisely engineered to work in harmony with the overall structure while fulfilling its specific role in the load-bearing system.

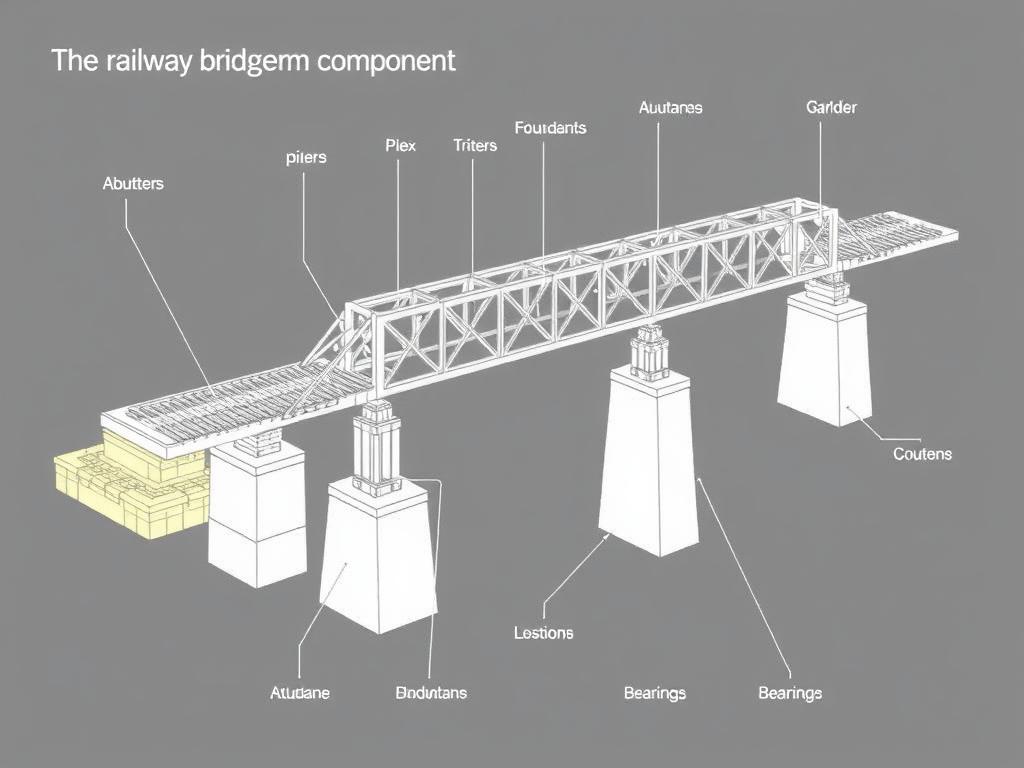

Foundations and Substructure

The foundation system forms the critical base upon which the entire railway bridge structure rests. These elements transfer the combined dead and live loads into the supporting ground. Depending on soil conditions and load requirements, engineers may employ spread footings, pile foundations, or caisson foundations.

Abutments and piers constitute the primary substructure elements. Abutments serve as the end supports for the bridge span while providing the transition between the bridge and approach embankments. Piers provide intermediate support for multi-span bridges and must resist both vertical loads and horizontal forces from braking trains, wind, and potential seismic activity.

Superstructure Elements

The superstructure comprises the main load-carrying components that span between supports. Primary elements include:

Girders and Beams

These horizontal structural members directly support the track system and transfer loads to the piers and abutments. Railway bridges commonly utilize steel plate girders, rolled steel sections, or prestressed concrete beams depending on span requirements and loading conditions.

Trusses

For longer spans, truss systems provide an efficient solution by using a framework of connected elements primarily in tension or compression. Common configurations include Warren, Pratt, and K-trusses, each offering specific advantages for different span requirements.

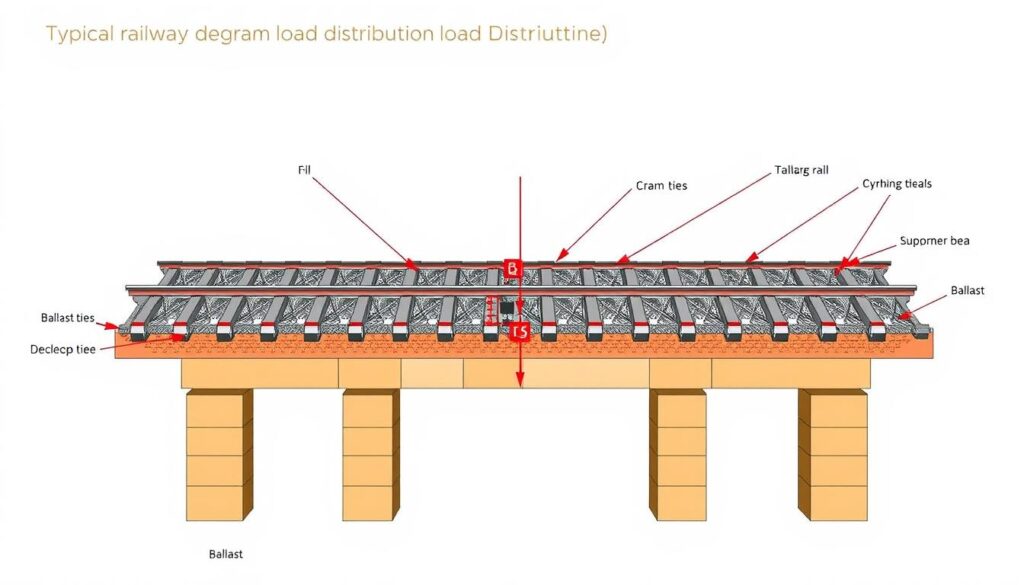

Load Distribution Systems

Railway bridges require sophisticated load distribution systems to safely transfer the concentrated forces from train wheels to the supporting structure. This typically involves:

- Track structure (rails, ties, and fastening systems)

- Ballast or direct fixation systems

- Bridge deck (concrete slab, orthotropic steel deck, or composite systems)

- Cross beams and stringers for load distribution

- Bearings that accommodate movement while transferring loads

Need Detailed Component Specifications?

Access our comprehensive railway bridge component guide with detailed specifications, material requirements, and design considerations for all structural elements.

Critical Factors Influencing Railway Bridge Structural Design

Railway bridge design requires careful consideration of numerous factors that significantly impact structural performance, safety, and longevity. Understanding these critical influences helps engineers develop optimal solutions for specific project requirements.

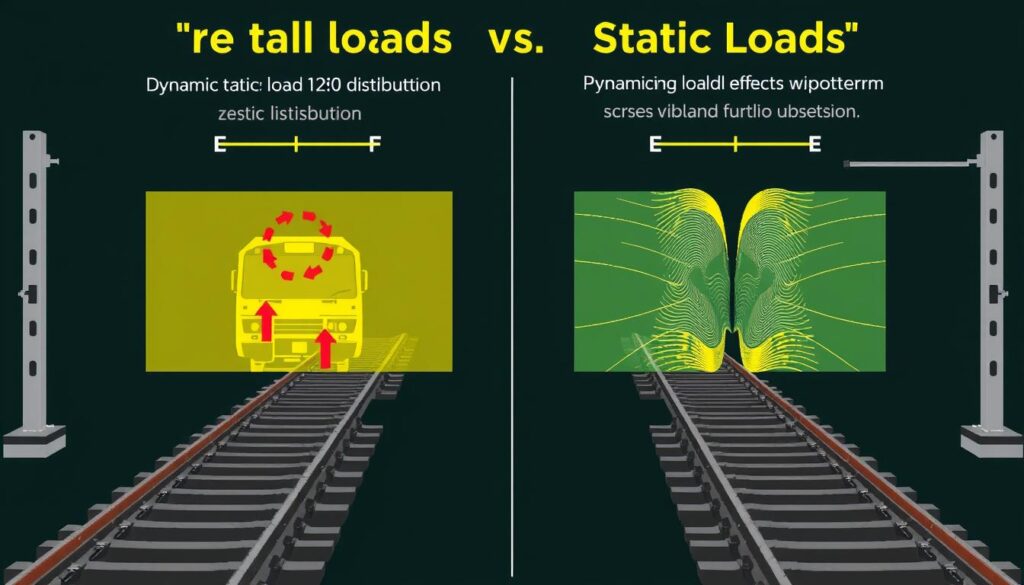

Dynamic Train Loads vs. Static Loads

Unlike highway bridges, railway bridges must withstand highly concentrated dynamic loads that create significant impact forces. These dynamic effects can amplify static loads by 40-60% depending on train speed, track conditions, and bridge configuration.

Key considerations for dynamic loading include:

- Impact factors that account for speed, track irregularities, and vehicle dynamics

- Resonance effects, particularly for high-speed rail applications

- Fatigue loading from repeated stress cycles

- Lateral forces from train hunting movements and centrifugal forces on curved tracks

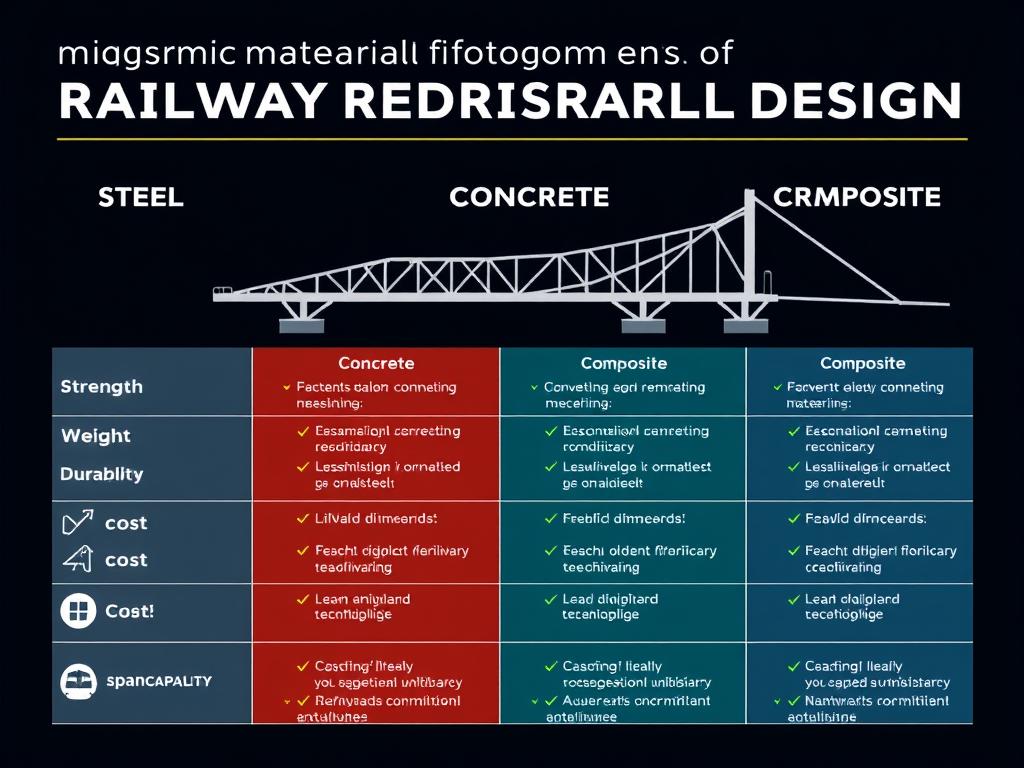

Material Selection Considerations

The choice of construction materials significantly impacts a railway bridge’s performance, durability, and life-cycle costs. Engineers must carefully evaluate material properties against project requirements.

Steel

Offers high strength-to-weight ratio, excellent for long spans, and provides good fatigue resistance. Modern weathering steels reduce maintenance requirements by forming protective patinas that minimize corrosion.

Concrete

Provides durability, fire resistance, and mass that helps dampen vibrations. Prestressed and post-tensioned concrete solutions offer enhanced performance for medium spans with reduced maintenance requirements.

Composite Systems

Combining steel and concrete creates efficient systems that leverage the strengths of both materials. Fiber-reinforced polymers (FRP) offer corrosion resistance and light weight for specific applications.

Environmental Considerations

Environmental factors significantly impact railway bridge design decisions and long-term performance. Engineers must account for:

Climate and Weather

Temperature fluctuations cause thermal expansion and contraction that must be accommodated through appropriate bearing systems and expansion joints. Extreme weather events require robust design parameters for wind loads, snow accumulation, and potential flooding conditions.

Seismic Activity

In seismically active regions, railway bridges require specialized design approaches to withstand ground acceleration forces. This may include isolation bearings, ductile detailing, and redundant load paths to prevent catastrophic failure during seismic events.

Optimize Your Railway Bridge Design

Our team of specialized structural engineers can help you navigate complex design factors for your specific project requirements.

Modern Innovations in Railway Bridge Structural Design

The field of railway bridge engineering continues to evolve with technological advancements that enhance safety, efficiency, and sustainability. These innovations are transforming how bridges are designed, constructed, and maintained throughout their service life.

Sensor-Based Monitoring Systems

Modern railway bridges increasingly incorporate sophisticated structural health monitoring (SHM) systems that provide real-time data on performance and condition. These systems utilize various sensor technologies:

- Strain gauges that measure deformation under loading

- Accelerometers that detect vibration patterns and anomalies

- Displacement sensors that monitor bearing movements and deflections

- Fiber optic systems that provide distributed strain measurements

- Environmental sensors that track temperature, humidity, and corrosion potential

These monitoring systems enable condition-based maintenance approaches, early detection of potential issues, and validation of design assumptions through performance data. The integration of IoT technology allows for remote monitoring and automated alert systems when measurements exceed predetermined thresholds.

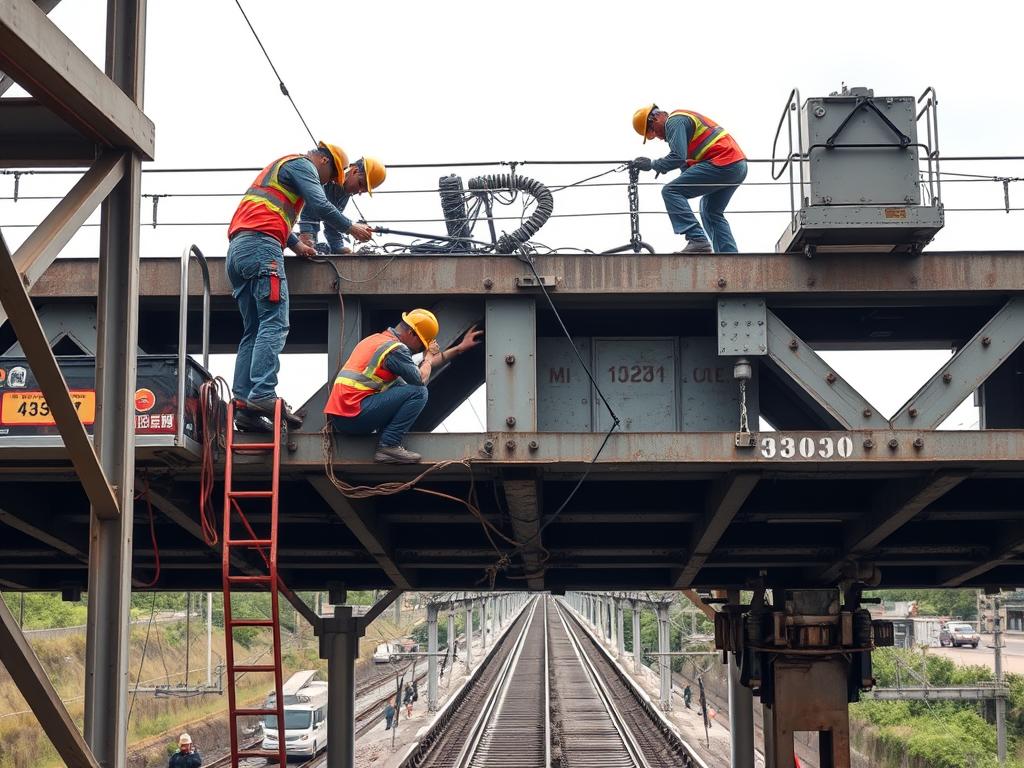

Prefabricated Modular Designs

Prefabrication and modular construction techniques are revolutionizing railway bridge implementation, particularly for replacement projects where track outage time must be minimized. These approaches offer several advantages:

- Improved quality control through factory fabrication

- Reduced on-site construction time and track possession requirements

- Minimized disruption to railway operations

- Enhanced worker safety through controlled manufacturing environments

- Potential for standardization across multiple bridge projects

Advanced connection systems facilitate rapid assembly while maintaining structural integrity. Self-propelled modular transporters (SPMTs) enable precise positioning of complete bridge spans during short track possession windows, sometimes as brief as 48-72 hours.

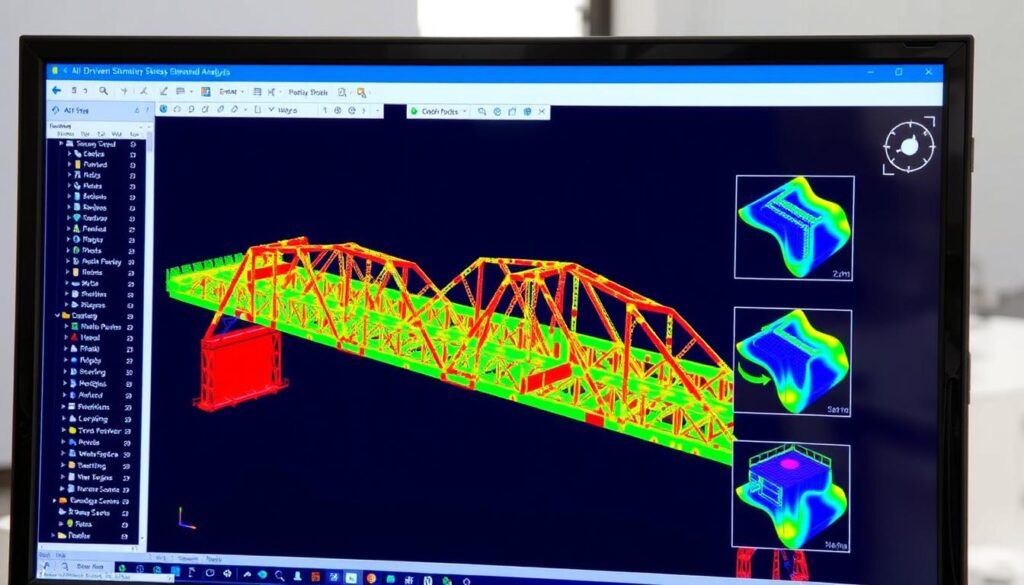

AI-Driven Stress Simulations

Artificial intelligence and machine learning technologies are transforming structural analysis and design optimization for railway bridges. These computational approaches enable:

- More accurate prediction of structural behavior under complex loading scenarios

- Optimization of material usage and structural configurations

- Identification of potential failure modes not apparent in traditional analysis

- Integration of multiple design variables and constraints simultaneously

- Predictive maintenance modeling based on cumulative damage algorithms

These advanced simulation capabilities allow engineers to explore innovative design solutions with greater confidence, potentially leading to more efficient structures with enhanced performance characteristics.

Stay at the Forefront of Bridge Technology

Discover how emerging technologies can be implemented in your railway infrastructure projects to improve performance and reduce lifecycle costs.

Real-World Examples of Successful Railway Bridge Designs

Examining successful railway bridge implementations provides valuable insights into practical applications of design principles and innovative approaches. The following case studies highlight diverse solutions to specific engineering challenges.

Danube Bridge Replacement, Austria

Location: Vienna-Bratislava rail corridor

Span Length: Main span 120 meters, total length 460 meters

Unique Engineering Solutions:

- Hybrid steel-concrete composite design optimizing material efficiency

- Integral abutments eliminating expansion joints and reducing maintenance

- Advanced corrosion protection system for extended service life

- Comprehensive monitoring system with over 200 sensors

- Construction methodology allowing continued rail operations during implementation

This project demonstrates how modern design approaches can address multiple constraints simultaneously, including navigational clearance requirements, environmental protection considerations, and minimal disruption to critical transportation infrastructure.

Seismic-Resistant Viaduct, Japan

Location: Shinkansen high-speed rail network

Span Length: Multiple spans of 35-40 meters, total length 3.2 kilometers

Unique Engineering Solutions:

- Lead-rubber bearing isolation systems at pier connections

- Tuned mass dampers to control dynamic response

- Reinforced concrete piers with ductile detailing

- Continuous structural health monitoring with automated alert system

- Designed to maintain serviceability after moderate seismic events

This project exemplifies how railway bridges in seismically active regions can be designed to not only survive major earthquakes but remain operational after moderate seismic events, maintaining critical transportation links when they are most needed.

Modular Replacement Bridge, United Kingdom

Location: East Coast Main Line

Span Length: 28 meters, single span

Unique Engineering Solutions:

- Fully prefabricated steel-concrete composite structure

- Innovative connection details enabling rapid assembly

- Installation completed during a 54-hour track possession

- Standardized design adaptable to multiple sites with minor modifications

- Integrated walkways and service ducts reducing future track access requirements

This project demonstrates how standardized, modular approaches can dramatically reduce implementation time and cost while maintaining high quality standards. The approach has since been replicated across multiple sites on the UK rail network.

Explore Detailed Case Studies

Access our complete library of railway bridge case studies with detailed engineering analyses, construction methodologies, and performance data.

Actionable Insights for Railway Bridge Engineers

Implementing effective railway bridge designs requires not only technical knowledge but also practical understanding of regulatory frameworks, maintenance considerations, and economic factors. The following insights provide guidance for engineering professionals involved in railway bridge projects.

Compliance with International Standards

Railway bridge design must adhere to rigorous standards that vary by jurisdiction. Key regulatory frameworks include:

| Standard | Region | Key Focus Areas | Recent Updates |

| AREMA Manual | North America | Load factors, fatigue requirements, material specifications | Enhanced provisions for high-speed rail applications |

| Eurocode 1 (Part 2) | European Union | Traffic loads, dynamic factors, load combinations | Revised fatigue assessment methodology |

| BS 5400 | United Kingdom | Structural analysis, material properties, durability | Transitioning to Eurocode with National Annexes |

| UIC Code 776-1 | International | Design loads for railway bridges, dynamic effects | Additional provisions for high-speed rail |

Successful compliance requires early engagement with regulatory authorities, thorough understanding of applicable standards, and documentation of design decisions throughout the project lifecycle. For international projects, reconciling different national standards often presents additional challenges requiring specialized expertise.

Maintenance Best Practices

Designing for maintainability significantly impacts lifecycle performance and costs. Key considerations include:

- Providing adequate access for inspection and maintenance activities

- Incorporating corrosion protection systems appropriate for the environment

- Designing replaceable wearing surfaces and components

- Implementing drainage systems that prevent water accumulation

- Developing comprehensive inspection and maintenance manuals

Preventive maintenance strategies based on regular inspection schedules help identify potential issues before they become critical. Modern approaches increasingly incorporate risk-based inspection frequencies that allocate resources according to structural criticality and condition assessment.

Cost Optimization Strategies

Balancing initial construction costs with long-term performance requires strategic decision-making throughout the design process. Effective approaches include:

- Conducting lifecycle cost analyses that consider initial, maintenance, and end-of-life costs

- Standardizing elements across multiple structures where appropriate

- Optimizing material usage through advanced analysis techniques

- Considering constructability early in the design process

- Evaluating resilience benefits against potential failure costs

Value engineering workshops involving multidisciplinary teams can identify cost-saving opportunities without compromising performance requirements. Early contractor involvement often yields constructability insights that reduce both cost and implementation risk.

Conclusion: The Future of Railway Bridge Structural Design

Railway bridge structural design continues to evolve as engineers balance traditional principles with emerging technologies and changing requirements. The integration of advanced materials, computational methods, and monitoring systems is enabling more efficient, durable, and resilient structures that meet the demands of modern railway operations.

As transportation networks expand and evolve, railway bridges will continue to play a critical role in infrastructure systems worldwide. By embracing innovation while maintaining focus on fundamental engineering principles, designers can create structures that not only meet immediate functional requirements but also provide sustainable service for generations to come.

The most successful railway bridge projects will be those that effectively balance technical performance, economic efficiency, environmental responsibility, and aesthetic considerations—creating infrastructure assets that serve as both engineering achievements and positive contributions to the built environment.

Advance Your Railway Bridge Engineering Knowledge

Join our community of infrastructure professionals to receive regular updates on railway bridge design innovations, case studies, and best practices.