The Critical Role of Ventilation Systems in Rail Tunnels

Rail tunnel ventilation systems serve multiple vital functions that directly impact safety, comfort, and operational efficiency. Understanding these core functions helps engineers develop comprehensive solutions that address all potential scenarios.

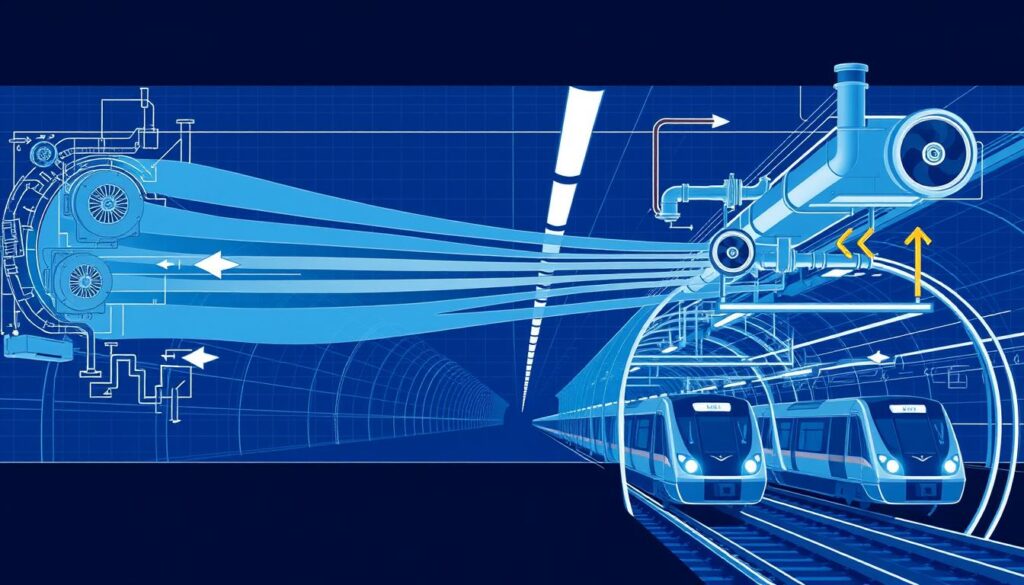

Figure 1: Typical airflow patterns in a rail tunnel ventilation system during normal operation

Fire Safety Management

The primary safety function of ventilation systems is smoke control during fire emergencies. By creating pressure differentials, these systems direct smoke away from evacuation routes, maintaining tenable conditions for passengers and enabling safe egress. They also facilitate access for emergency responders by keeping critical areas clear of smoke and toxic gases.

Air Quality Control

Rail tunnels accumulate various pollutants including particulate matter, nitrogen oxides, and carbon dioxide from train operations. Ventilation systems dilute and remove these contaminants, maintaining oxygen levels and preventing the buildup of harmful substances that could affect passenger health and comfort.

Temperature Regulation

The heat generated by train operations, electrical systems, and braking can significantly increase tunnel temperatures. Effective ventilation manages this thermal load, preventing equipment failures, reducing air conditioning demands on trains, and maintaining comfortable conditions for passengers on platforms and within stations.

According to NFPA 130 standards, rail tunnel ventilation systems must maintain tenable conditions for a minimum of 1 hour during emergency scenarios, with temperature not exceeding 60°C at 1.8m above the walkway.

Key Components of Rail Tunnel Ventilation Systems

Modern rail tunnel ventilation incorporates various components working in concert to create effective airflow management. The selection and configuration of these components depend on tunnel length, cross-sectional area, train frequency, and local environmental conditions.

Figure 2: Ceiling-mounted jet fans in a rail tunnel ventilation system

- Jet Fans: These axial flow fans create a longitudinal airflow through the tunnel by generating a high-velocity jet. Typically mounted on the ceiling or walls, jet fans are strategically positioned to minimize dead zones and ensure consistent air movement throughout the tunnel length.

- Axial Flow Fans: Located at ventilation shafts or stations, these large-capacity fans move substantial air volumes into or out of the tunnel system. They serve as the primary mechanical drivers for both supply and exhaust functions.

- Dampers and Louvers: These adjustable components control airflow direction and volume, allowing operators to reconfigure ventilation patterns based on operational needs or emergency scenarios.

- Ventilation Shafts: Vertical or inclined passages connect the tunnel to the surface, providing natural ventilation pathways and housing mechanical equipment for forced ventilation.

- Emergency Exhaust Systems: Dedicated high-temperature fans and ducts designed to extract smoke and hot gases during fire events, typically rated to operate at temperatures exceeding 250°C for extended periods.

Ventilation System Configurations

| System Type | Configuration | Advantages | Limitations | Best Application |

| Longitudinal | Airflow parallel to tunnel axis | Lower installation cost, simpler design | Limited smoke control in bidirectional tunnels | Short to medium tunnels with unidirectional traffic |

| Transverse | Airflow perpendicular to tunnel axis | Superior smoke control, uniform ventilation | Higher cost, complex ductwork | Long tunnels with high traffic volume |

| Semi-Transverse | Combined longitudinal and transverse elements | Good compromise of cost and performance | Moderate complexity in design and control | Medium to long tunnels with variable traffic |

| Single-Point Extraction | Concentrated extraction at strategic locations | Targeted smoke removal, lower energy use | Requires precise fire location detection | Tunnels with defined fire risk zones |

Figure 3: Comparison of longitudinal (left) and transverse (right) ventilation systems

Engineering Challenges in Rail Tunnel Ventilation

Designing effective ventilation systems for rail tunnels presents unique challenges that require sophisticated engineering solutions. These challenges span from emergency response capabilities to everyday operational efficiency.

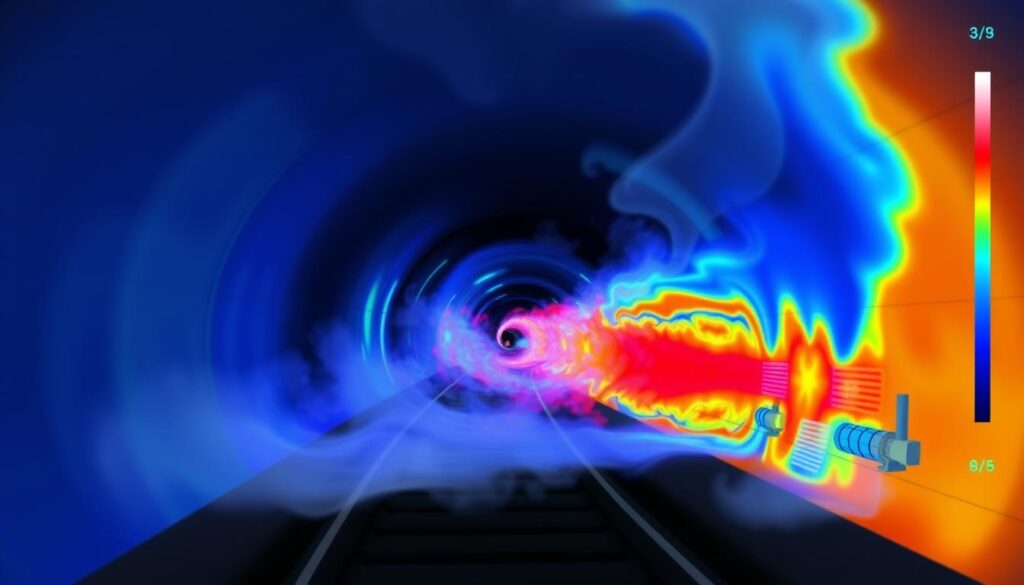

Figure 4: CFD simulation of smoke propagation during a tunnel fire emergency

Smoke Management During Fires

Fire scenarios in rail tunnels create complex thermodynamic conditions that ventilation systems must address. The “critical velocity” concept—the minimum airflow required to prevent smoke backlayering against the ventilation direction—forms the foundation of emergency ventilation design. Engineers must calculate this velocity based on potential fire heat release rates, tunnel geometry, and grade.

“The most challenging aspect of rail tunnel ventilation engineering is designing systems that can rapidly adapt to changing emergency conditions while maintaining tenable environments in evacuation routes.”

Particulate Filtration and Air Quality

Modern rail tunnel ventilation must address increasingly stringent air quality requirements. Particulate matter from train operations, especially in older diesel systems, requires effective filtration solutions. Advanced systems now incorporate:

- Electrostatic precipitators for fine particle removal

- NOx scrubbers for diesel exhaust treatment

- Activated carbon filters for odor control

- Real-time air quality monitoring with automated response systems

Energy Efficiency Optimization

Ventilation systems represent one of the largest energy consumers in tunnel operations. Engineers must balance safety requirements with energy efficiency through:

Figure 5: Variable frequency drive controllers optimize fan energy consumption

Demand-Based Ventilation: Systems that adjust airflow based on real-time air quality measurements, train schedules, and occupancy levels can reduce energy consumption by 30-40% compared to constant-volume systems.

High-Efficiency Motors: Modern EC (electronically commutated) motors and variable frequency drives allow fans to operate at optimal efficiency points across varying demand conditions, significantly reducing energy consumption during non-peak periods.

Real-World Case Studies in Rail Tunnel Ventilation

Examining successful implementations provides valuable insights into practical applications of ventilation engineering principles. These case studies highlight innovative approaches to complex ventilation challenges.

Gotthard Base Tunnel, Switzerland

Figure 6: Ventilation infrastructure in the Gotthard Base Tunnel

At 57 km, the Gotthard Base Tunnel is the world’s longest and deepest rail tunnel. Its ventilation system incorporates:

- Multiple intermediate access shafts serving as ventilation points

- Separate emergency stations with dedicated smoke extraction systems

- Pressure relief ducts to manage aerodynamic effects of high-speed trains

- Automated control systems that respond to train positions and environmental conditions

The system successfully maintains air quality despite the extreme length and depth, with air exchange rates calibrated to handle both normal operations and emergency scenarios.

Channel Tunnel (Eurotunnel)

The 50.5 km Channel Tunnel connecting the UK and France features a sophisticated ventilation system designed to handle its unique undersea environment:

Figure 7: Cross-section of Channel Tunnel showing the three-tunnel ventilation concept

- Three parallel tunnels (two rail tunnels and a service tunnel) with cross-passages

- Pressure differential system maintaining the service tunnel at positive pressure

- Supplementary cooling system to manage the significant heat load

- Dedicated fire suppression and smoke management capabilities

Following a significant fire incident in 1996, the ventilation system underwent enhancements to improve emergency response capabilities, demonstrating the evolutionary nature of tunnel safety engineering.

Seoul Metro Line 9 Extension

Seoul’s newest metro line incorporates state-of-the-art ventilation engineering tailored to urban density challenges:

Figure 8: Centralized ventilation control center for Seoul Metro Line 9

- Platform screen doors integrated with the ventilation strategy

- Zoned ventilation approach with independent control of station and tunnel sections

- Heat recovery systems that capture and repurpose waste heat

- AI-driven predictive control systems optimizing performance based on passenger flow patterns

Current Innovations in Rail Tunnel Ventilation

The field of rail tunnel ventilation continues to evolve with technological advancements that enhance safety, efficiency, and sustainability. These innovations are reshaping how engineers approach ventilation design.

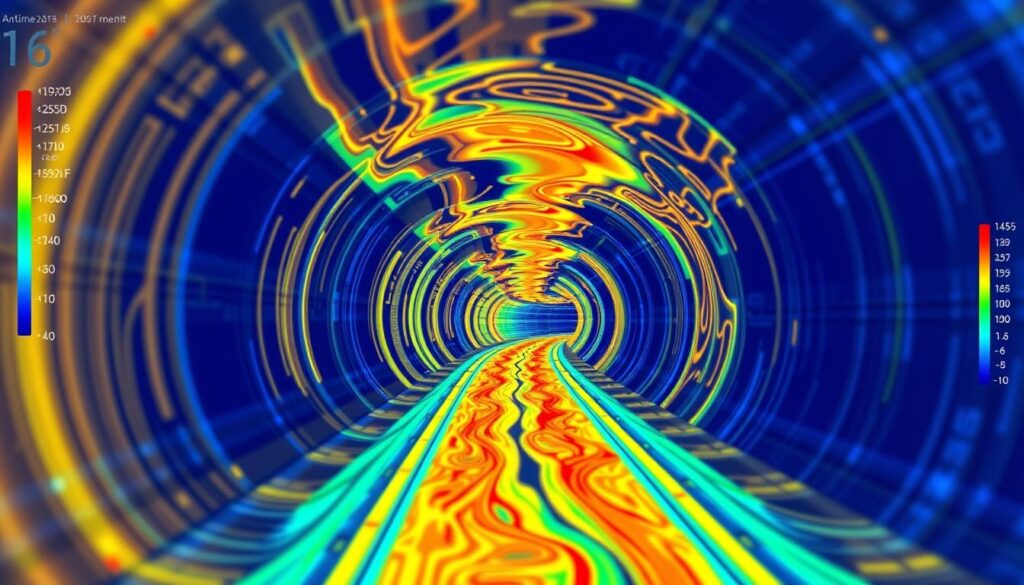

Figure 9: AI-enhanced computational modeling for ventilation optimization

AI-Driven Airflow Modeling

Artificial intelligence and machine learning are revolutionizing ventilation design through:

- Predictive modeling that simulates thousands of potential emergency scenarios

- Real-time optimization algorithms that continuously adjust ventilation parameters

- Digital twins that mirror physical systems for testing and training

- Automated fault detection and diagnostic systems

Advanced Disaster-Response Ventilation Protocols

Modern ventilation systems incorporate sophisticated emergency response capabilities:

Figure 10: Emergency ventilation control systems with automated response protocols

- Automated smoke extraction systems that activate based on fire detection

- Zoned pressure control that isolates affected areas while maintaining safe evacuation routes

- Resilient power systems with multiple redundancies

- Remote operation capabilities for hazardous conditions

Eco-Friendly Materials and Sustainable Design

Sustainability has become a central consideration in modern ventilation engineering:

- Low-VOC materials for ducts and components

- Biodegradable lubricants for mechanical systems

- Energy recovery systems that capture waste heat

- Solar and geothermal integration for auxiliary power

According to recent industry studies, implementing energy-efficient ventilation strategies can reduce a rail tunnel’s operational carbon footprint by up to 25% over its lifetime.

Safety Standards and Regulatory Compliance

Rail tunnel ventilation must adhere to stringent safety standards that vary by jurisdiction but share common principles focused on life safety and operational resilience.

Figure 11: Compliance testing of ventilation performance using smoke visualization

NFPA 130 Requirements

The National Fire Protection Association’s Standard for Fixed Guideway Transit and Passenger Rail Systems (NFPA 130) establishes comprehensive requirements for ventilation systems:

- Emergency ventilation must maintain tenable conditions along evacuation routes

- Systems must be capable of reaching full operational capacity within 60 seconds

- Minimum airflow velocities must prevent smoke backlayering

- Redundant power supplies must ensure operation during emergencies

- Regular testing and maintenance protocols must be established

EU Directive 2004/54/EC

European standards for tunnel safety include specific ventilation requirements:

- Mechanical ventilation is mandatory for tunnels exceeding 1000m

- Longitudinal ventilation is restricted in bidirectional tunnels over certain lengths

- Emergency stations with smoke extraction capabilities are required at specified intervals

- Control systems must interface with broader emergency management infrastructure

Compliance with safety standards requires not only proper design but also ongoing commissioning, testing, and maintenance. Many tunnel ventilation failures occur due to inadequate maintenance rather than design flaws.

Future Trends in Rail Tunnel Ventilation Engineering

The evolution of rail tunnel ventilation continues with emerging technologies and approaches that promise to further enhance safety, efficiency, and sustainability.

Hydrogen-Powered Ventilation Systems

As the transportation sector embraces hydrogen technology, ventilation systems are following suit:

- Hydrogen fuel cells providing clean backup power for critical ventilation

- Combined heat and power systems utilizing hydrogen for both energy and thermal management

- Zero-emission emergency power solutions replacing diesel generators

IoT-Enabled Monitoring and Predictive Maintenance

Smart infrastructure is transforming ventilation management:

- Distributed sensor networks providing comprehensive environmental data

- Predictive maintenance algorithms identifying potential failures before they occur

- Remote diagnostics reducing the need for physical inspections

- Blockchain-secured operational data ensuring regulatory compliance

Integrated Approach to Tunnel Systems

Future designs will increasingly view ventilation as part of a holistic tunnel system:

- Ventilation integrated with aerodynamic train design considerations

- Combined approaches to ventilation, lighting, and communication infrastructure

- Unified control systems managing all tunnel environmental parameters

- Life-cycle assessment driving design decisions

Conclusion

Rail tunnel ventilation engineering represents a critical intersection of safety science, fluid dynamics, and mechanical engineering. As rail networks expand globally and climate considerations intensify, the importance of efficient, reliable ventilation systems will only grow. By embracing technological innovations while adhering to fundamental safety principles, engineers can create ventilation solutions that protect passengers, support operational efficiency, and contribute to sustainable transportation infrastructure.

Need Expert Ventilation Engineering Support?

Our team of specialized engineers provides comprehensive ventilation design, analysis, and compliance services for rail tunnel projects worldwide. From initial concept development to system commissioning, we deliver solutions that prioritize safety, efficiency, and regulatory compliance.