Can a career in pipeline design be both challenging and rewarding? For those who are passionate about creating complex systems that transport essential materials, the answer is yes. Pipeline engineers play a critical role in today’s infrastructure, ensuring the safe and efficient transportation of oil, gas, and other vital resources.

To succeed in this field, one must start with a strong educational foundation in engineering, gain hands-on experience, and sharpen problem-solving skills. By following these steps, aspiring pipeline engineers can carve their path to success.

Key Takeaways

- Strong educational foundation in engineering is crucial.

- Hands-on experience is essential for success.

- Sharpening problem-solving skills is vital.

- Understanding industry-specific terminology is necessary.

- Mastering pipeline engineering requires dedication and hard work.

Introduction to Pipeline Engineering

Understanding pipeline engineering is essential for the safe and efficient distribution of energy resources. Pipeline engineering covers a range of topics including design, construction, operation, and maintenance. It is a critical discipline that ensures the integrity of pipeline systems, which are vital for the transportation of oil, gas, and other materials.

What is Pipeline Engineering?

Pipeline engineering encompasses various aspects, including the design and construction of pipelines, selection of appropriate pipeline materials, and ensuring the integrity of the pipeline system. Standards such as ASME B31.4 and B31.8 are widely used in the industry to guide the design, construction, and operation of pipelines. The field requires a deep understanding of fluid mechanics and stress analysis to ensure that pipelines are designed to withstand various operational conditions.

Importance of Pipeline Engineering in Industry

The importance of pipeline engineering in the industry cannot be overstated. Pipelines are a critical component of the global energy infrastructure, facilitating the transportation of oil, gas, and other materials across vast distances. Effective pipeline construction and maintenance are crucial for preventing accidents and ensuring the reliable supply of energy resources. Moreover, advancements in pipeline materials and engineering techniques have improved the safety and efficiency of pipeline operations.

Pipeline engineering also plays a significant role in the economy, as it directly impacts the cost and availability of energy resources. By ensuring the integrity of pipeline systems, pipeline engineers contribute to the overall stability of the energy market.

Key Principles of Pipeline Engineering

To design and maintain pipelines that are safe and efficient, it’s essential to grasp the key principles of pipeline engineering. These principles form the backbone of ensuring pipeline integrity and longevity.

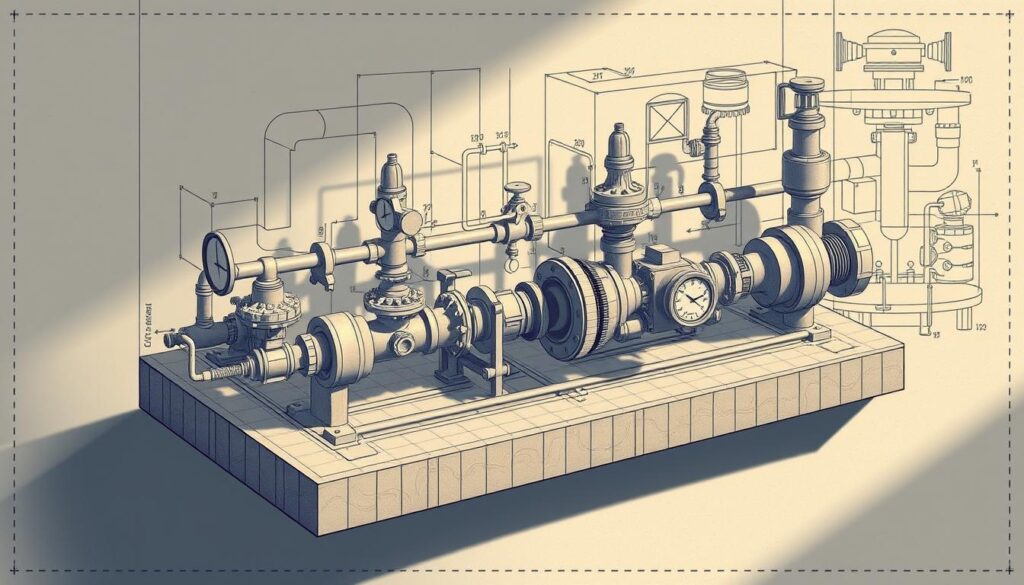

Fluid Mechanics and Pipeline Design

Fluid mechanics plays a critical role in pipeline design. Understanding how fluids behave under various conditions is crucial for designing pipelines that can efficiently transport liquids or gases over long distances. As noted by experts, “The application of fluid mechanics in pipeline design is not just about transporting fluids; it’s about doing so safely and efficiently.”

“The design of a pipeline system must consider the fluid properties, flow rates, and pressure requirements to ensure safe and efficient operation.”

The design process involves calculating the optimal pipeline diameter, selecting appropriate materials, and determining the required pumping power. This ensures that the pipeline operates within safe limits, minimizing the risk of failures.

Material Selection for Pipelines

The selection of materials for pipelines is another critical principle. The material chosen must be able to withstand the internal pressures, external loads, and environmental conditions. Material strength and durability are key factors that influence the longevity and integrity of the pipeline.

- Resistance to corrosion

- Ability to withstand high pressures

- Flexibility and toughness

Materials such as steel and plastic are commonly used, each with its advantages and disadvantages. The choice of material depends on the specific application and environmental conditions.

Stress Analysis and Management

Stress analysis is vital for understanding how pipelines respond to various loads and stresses. This includes internal pressure, temperature changes, and external forces. Effective stress management involves designing the pipeline to mitigate these stresses, thereby preventing failures.

Stress analysis techniques, including finite element analysis, are used to simulate the behavior of pipelines under different conditions. This helps in identifying potential failure points and optimizing the design.

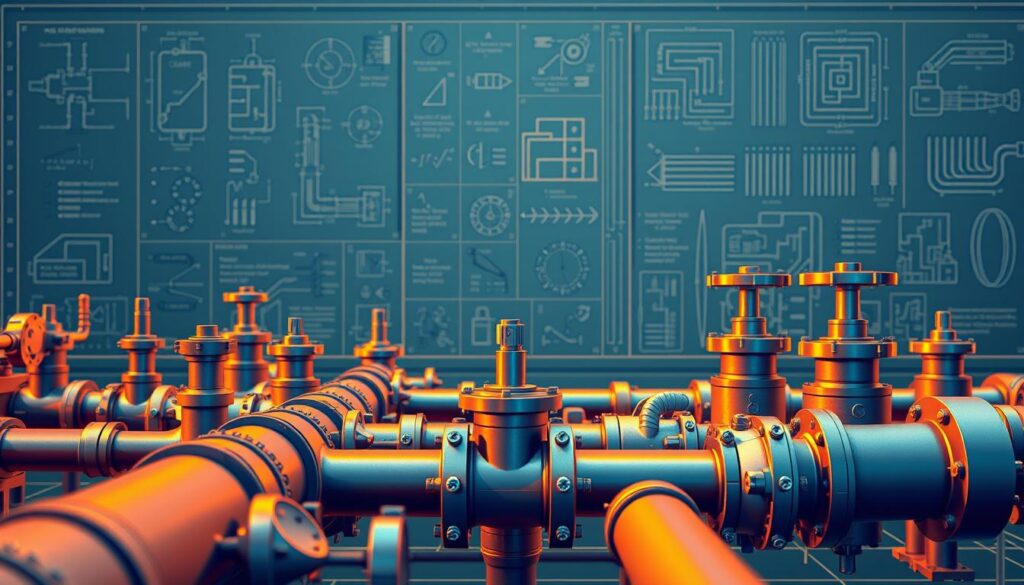

Types of Pipelines

Understanding the different types of pipelines is essential for effective pipeline management and maintenance. Pipelines are categorized based on their application, and each type has its unique requirements and challenges.

Oil and Gas Pipelines

Oil and gas pipelines are critical infrastructure for the energy sector, responsible for transporting crude oil, natural gas, and refined products over long distances. These pipelines are designed to withstand high pressures and are typically made from high-strength steel. The construction and maintenance of oil and gas pipelines require specialized equipment and techniques to ensure safety and efficiency.

Water and Sewer Pipelines

Water and sewer pipelines are vital for public health, providing clean water and sanitation services. These pipelines are often made from materials like PVC, ductile iron, or concrete, chosen for their durability and resistance to corrosion. Regular inspection and maintenance of water and sewer pipelines are crucial to prevent leaks and ruptures that could lead to significant environmental and health issues.

Industrial Pipelines

Industrial pipelines are used in various manufacturing processes to transport chemicals, raw materials, and finished products. These pipelines must be designed and constructed to meet the specific needs of the industry, including resistance to corrosion and the ability to handle high temperatures and pressures. Effective pipeline management in industrial settings is key to ensuring operational efficiency and safety.

In conclusion, the different types of pipelines play crucial roles in their respective industries. Understanding their unique characteristics and requirements is essential for effective pipeline construction, inspection, and maintenance. By adopting best practices and leveraging advanced technologies, industries can ensure the integrity and reliability of their pipeline infrastructure.

Pipeline Design Process

The pipeline design process is a critical phase that requires meticulous planning and execution to ensure the successful completion of a pipeline project. Effective pipeline project management is crucial during this phase to minimize risks and ensure compliance with regulatory standards.

Initial Planning and Feasibility Studies

The initial planning stage involves conducting feasibility studies to determine the viability of the pipeline project. This includes assessing the terrain, environmental impact, and potential risks associated with the project. For instance, Team Pipeline emphasizes the importance of thorough feasibility studies in their project management approach.

- Conducting topographic surveys to identify the most suitable route for the pipeline.

- Assessing environmental factors, such as water bodies and wildlife habitats.

- Evaluating the social impact on local communities.

Routing and Site Selection

Routing and site selection are critical components of the pipeline design process. The chosen route must be economically viable, safe, and environmentally friendly. Key considerations include:

- Minimizing the length of the pipeline while avoiding sensitive ecosystems.

- Ensuring the route is accessible for construction and maintenance.

- Complying with regulatory requirements and land-use policies.

Design Specifications and Standards

Adherence to design specifications and standards is essential for ensuring the pipeline’s safety and efficiency. This includes:

- Selecting materials that meet industry standards for strength and durability.

- Designing the pipeline to withstand various environmental conditions.

- Implementing safety features, such as pressure management systems.

By following these guidelines and leveraging expertise in pipeline design, projects can be completed on time, within budget, and to the required quality standards.

Regulatory Framework

Understanding the regulatory framework is crucial for the successful execution of pipeline engineering projects. The regulatory environment ensures that pipelines are designed, constructed, and maintained in a manner that prioritizes safety and minimizes environmental impact.

Federal Regulations for Pipeline Engineering

Federal regulations play a pivotal role in governing pipeline engineering. Agencies such as the Department of Transportation (DOT) and the Health and Safety Executive (HSE) set forth guidelines that pipeline operators must follow to ensure pipeline integrity and safety. These regulations cover various aspects, including design, construction, and maintenance.

For instance, the DOT’s Pipeline and Hazardous Materials Safety Administration (PHMSA) regulates the transportation of hazardous materials through pipelines, emphasizing the importance of pipeline inspection and maintenance to prevent accidents.

State and Local Regulations

In addition to federal regulations, state and local laws also govern pipeline engineering. These regulations can vary significantly from one jurisdiction to another, making it essential for pipeline operators to be aware of and comply with the specific requirements of each region in which they operate.

State regulations may include specific requirements for pipeline routing, construction standards, and emergency response planning. Local regulations might focus on zoning laws and permits required for pipeline construction and maintenance.

Environmental Impact Assessment

An Environmental Impact Assessment (EIA) is a critical component of the regulatory framework for pipeline engineering. The EIA process involves evaluating the potential environmental impacts of a proposed pipeline project, including effects on wildlife habitats, water resources, and air quality.

According to the National Academies report, a thorough EIA is essential for identifying potential environmental risks and developing strategies to mitigate them, ensuring that pipeline projects are executed in an environmentally responsible manner.

Pipeline Construction Techniques

Pipeline construction involves a range of methods and techniques tailored to different terrains and pipeline types. The success of a pipeline project heavily relies on the construction techniques employed, from initial trenching to the final quality assurance checks.

Trenching and Boring Methods

Trenching and boring are fundamental techniques in pipeline construction. Trenching involves digging a trench for the pipeline, while boring is used for crossing under obstacles like rivers or roads. According to the Pipeline and Hazardous Materials Safety Administration, the choice between trenching and boring depends on environmental factors and the terrain.

The trenching process requires careful planning to avoid environmental damage and ensure the stability of the trench. Boring, on the other hand, involves using specialized equipment to drill under the surface, minimizing the impact on the environment above.

Materials Handling and Installation

The handling and installation of pipeline materials are critical phases in the construction process. Pipelines are made from a variety of materials, including steel, plastic, and concrete, each with its own handling requirements. Proper storage, transportation, and installation techniques are essential to prevent damage and ensure the integrity of the pipeline.

As noted by experts in civil engineering project management,

“The quality of pipeline materials and the precision in their installation directly affect the pipeline’s durability and performance.”

Therefore, adhering to strict standards during materials handling and installation is crucial.

| Material | Characteristics | Typical Use |

|---|---|---|

| Steel | High strength, durability | High-pressure pipelines |

| Plastic | Corrosion-resistant, flexible | Water and gas distribution |

| Concrete | High compressive strength | Large diameter pipelines |

Quality Assurance in Construction

Quality assurance is a vital aspect of pipeline construction, ensuring that the pipeline is built to last and operates safely. This involves rigorous testing and inspection during and after construction. Techniques such as hydrostatic testing and non-destructive evaluation (NDE) are used to verify the integrity of the pipeline.

For more insights on project management in civil engineering, including pipeline construction, visit World Civil Society. Effective quality assurance practices not only enhance the safety and reliability of the pipeline but also contribute to the overall success of the project.

Maintenance and Inspection

Effective maintenance and inspection are crucial for the longevity and safety of pipelines. Regular checks help identify potential issues before they escalate into major problems, ensuring the pipeline operates smoothly and efficiently.

Importance of Regular Inspections

Regular inspections are vital for detecting signs of wear, corrosion, or damage. By identifying these issues early, operators can undertake necessary repairs or replacements, thereby preventing costly failures and enhancing safety.

Key benefits of regular inspections include:

- Early detection of potential failures

- Reduced risk of accidents

- Extended pipeline lifespan

- Compliance with regulatory requirements

Common Maintenance Practices

Maintenance practices vary depending on the type of pipeline and its operating conditions. Common practices include:

| Maintenance Activity | Description | Frequency |

|---|---|---|

| Pigging | Cleaning the pipeline using pigs to remove debris | Quarterly |

| Corrosion Inspection | Inspecting for signs of corrosion or damage | Annually |

| Leak Detection | Monitoring for leaks using various technologies | Continuously |

Technological Advances in Inspection

Technological advancements have significantly improved pipeline inspection techniques. Modern tools and methods, such as smart pigs equipped with sensors and drones for aerial inspections, provide more accurate and detailed data.

The use of advanced technologies like artificial intelligence and machine learning is enhancing the analysis of inspection data, enabling predictive maintenance and reducing the likelihood of unexpected failures.

Pipeline Safety and Risk Management

Pipeline safety involves a multifaceted approach that includes risk assessment, emergency planning, and adherence to safety standards. Ensuring the safety of pipelines is paramount to prevent accidents, protect the environment, and maintain public trust.

Identifying and Assessing Risks

The first step in pipeline safety is identifying and assessing potential risks. This involves analyzing the pipeline’s design, materials, and operating conditions to pinpoint vulnerabilities. Risk assessment is a systematic process that helps in understanding the likelihood and potential impact of various hazards.

- Internal corrosion due to the transported fluid

- External damage from third-party activities

- Material defects or manufacturing flaws

- Natural disasters such as earthquakes or floods

By identifying these risks, pipeline operators can implement targeted measures to mitigate them, thus enhancing overall safety.

Emergency Response Planning

Despite best efforts to prevent accidents, having a robust emergency response plan is crucial. This plan outlines the procedures to be followed in case of a pipeline failure or other emergencies, ensuring a swift and effective response to minimize damage.

- Detection and notification of the incident

- Assessment of the situation and activation of the response team

- Containment and mitigation of the incident

- Coordination with local authorities and emergency services

Regular drills and training exercises are essential to ensure that all personnel are familiar with the emergency response plan.

Safety Standards and Training

Adherence to safety standards and comprehensive training programs is vital for maintaining a safe working environment. Pipeline operators must comply with relevant regulations and industry standards, such as those set by the American Society of Mechanical Engineers (ASME).

| Safety Standard | Description | Benefit |

|---|---|---|

| ASME B31.4 | Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids | Ensures safe design, construction, and operation of liquid pipelines |

| ASME B31.8 | Gas Transmission and Distribution Piping Systems | Covers safety standards for gas pipelines, including design, materials, and operation |

Regular training and certification programs for personnel involved in pipeline operations are critical for ensuring that they are aware of the latest safety protocols and best practices.

Advances in Pipeline Engineering

The evolution of pipeline engineering is marked by significant developments in smart technologies and automation. As the industry continues to grow, innovations in materials, technologies, and monitoring systems are playing a crucial role in enhancing pipeline efficiency, safety, and management.

Innovations in Pipeline Materials

Recent advancements in pipeline materials have led to the development of more durable and resistant pipelines. New materials and coatings are being designed to withstand harsh environmental conditions, reduce corrosion, and increase the lifespan of pipelines.

For instance, the use of advanced composites and corrosion-resistant alloys is becoming more prevalent. These materials not only improve the structural integrity of pipelines but also reduce maintenance needs.

“The development of new pipeline materials is crucial for the future of pipeline engineering, enabling the construction of safer and more efficient pipelines.”

Smart Pipeline Technologies

Smart pipeline technologies are revolutionizing the way pipelines are monitored and managed. These technologies include advanced sensors and real-time monitoring systems that detect anomalies, predict potential failures, and optimize pipeline operations.

The integration of Internet of Things (IoT) devices in pipeline management allows for more precise and timely data collection, enabling proactive maintenance and reducing the risk of accidents.

Automation and Monitoring Systems

Automation and monitoring systems are critical components of modern pipeline engineering. These systems utilize advanced software and hardware to automate pipeline operations, monitor pipeline conditions, and respond to incidents in real-time.

The use of SCADA (Supervisory Control and Data Acquisition) systems is a prime example of how automation enhances pipeline management. SCADA systems provide comprehensive control and monitoring capabilities, improving the overall efficiency and safety of pipeline operations.

As the industry continues to adopt these advancements, the future of pipeline engineering looks promising, with potential for even greater improvements in safety, efficiency, and environmental sustainability.

Environmental Considerations

Environmental considerations are now at the forefront of pipeline engineering practices. As the demand for energy and resources continues to grow, the need to minimize the ecological footprint of pipeline operations has become increasingly important.

Minimizing Environmental Impact

Minimizing environmental impact involves several key strategies, including careful planning and execution of pipeline routes, implementation of advanced technologies to detect potential leaks, and adherence to stringent environmental regulations. By adopting these practices, pipeline engineers can significantly reduce the risk of environmental damage.

Key Measures to Minimize Impact:

- Conducting thorough environmental impact assessments

- Implementing spill response plans

- Using eco-friendly materials in pipeline construction

For more information on how environmental engineering is shaping a sustainable future, visit https://worldcivilsociety.com/environmental-engineering-shaping-a-sustainable-future/.

Remediation Techniques for Pipeline Spills

Despite best efforts, pipeline spills can still occur. Effective remediation techniques are crucial to mitigate the environmental impact of such incidents. Techniques include containment and cleanup of spills, restoration of affected habitats, and monitoring of environmental health post-incident.

Remediation Techniques:

| Technique | Description | Effectiveness |

|---|---|---|

| Containment Booms | Used to contain oil spills | High |

| Bioremediation | Utilizes microorganisms to clean pollutants | Medium to High |

| Physical Removal | Involves removing contaminated soil or water | High |

Sustainable Practices in Pipeline Engineering

Sustainable practices are integral to modern pipeline engineering. This includes the use of sustainable materials, energy-efficient technologies, and practices that minimize waste and reduce environmental footprint. By embracing sustainability, pipeline engineers can ensure that their projects are not only economically viable but also environmentally responsible.

Sustainable Practices:

- Using recycled materials in pipeline construction

- Implementing energy-efficient pumping systems

- Minimizing land use through optimized routing

Economic Implications

Understanding the economic aspects of pipeline projects is crucial for stakeholders, encompassing cost analysis, funding strategies, and economic returns. Pipeline projects are significant investments that can have far-reaching economic implications.

Cost Analysis in Pipeline Projects

Cost analysis is a critical component of pipeline project management. It involves assessing various costs, including materials, labor, and equipment expenses. A thorough cost analysis helps in budgeting and financial planning, ensuring that the project is economically viable.

Key components of cost analysis include:

- Material costs, including pipes and fittings

- Labor costs, encompassing construction and installation expenses

- Equipment costs, such as trenching and boring machinery

- Contingency planning for unexpected expenses

Funding and Investment Opportunities

Securing funding is a pivotal step in the execution of pipeline projects. Various funding options are available, including government grants, private investments, and public-private partnerships. Understanding these opportunities is essential for project viability.

Investment opportunities in pipeline projects can be attractive due to their potential for long-term returns. Investors look for projects with robust financial planning and risk management strategies.

Economic Benefits of Pipeline Projects

Pipeline projects can generate significant economic benefits, including job creation, economic growth, and increased energy or water supply reliability. These benefits can have a positive impact on local and national economies.

The economic benefits of pipeline projects can be substantial, contributing to:

- Job creation during construction and maintenance phases

- Economic growth through increased investment

- Improved supply chain reliability

In conclusion, understanding the economic implications of pipeline projects is vital for their success. By conducting thorough cost analyses, securing appropriate funding, and realizing economic benefits, stakeholders can ensure that these projects contribute positively to the economy.

Case Studies in Pipeline Engineering

Examining case studies in pipeline engineering provides valuable insights into best practices and potential pitfalls. These real-world examples offer a unique opportunity to learn from both successes and failures, ultimately enhancing the field.

Successful Pipeline Projects

Several pipeline projects have been notable for their success, showcasing innovative solutions and meticulous planning. For instance, the Trans-Alaska Pipeline System is a landmark example of overcoming extreme environmental challenges. Built to withstand harsh arctic conditions, this pipeline demonstrates the importance of robust design and material selection.

- The use of advanced materials and coatings to resist corrosion and extreme temperatures.

- Implementation of sophisticated monitoring systems to detect potential issues early.

- Effective project management and collaboration among stakeholders.

Lessons Learned from Failures

Conversely, there have been significant pipeline failures that have taught the industry valuable lessons. The San Bruno pipeline explosion in 2010 is a critical case study that highlighted the importance of pipeline integrity management and the need for rigorous inspection and maintenance protocols.

- The necessity of regular inspections and maintenance to prevent catastrophic failures.

- The importance of implementing safety standards and training for personnel.

- The need for transparent communication and emergency response planning.

Innovations Derived from Past Experiences

Past experiences, both successes and failures, have driven innovations in pipeline engineering. Advances in pipeline design and materials science have improved the safety and efficiency of pipeline operations. For example, the development of smart pipeline technologies enables real-time monitoring and predictive maintenance, reducing the risk of failures.

| Innovation | Description | Benefit |

|---|---|---|

| Smart Pipeline Technologies | Real-time monitoring and predictive maintenance | Reduced risk of failures |

| Advanced Materials | Improved resistance to corrosion and damage | Enhanced pipeline integrity |

| Enhanced Inspection Techniques | More accurate and efficient inspection methods | Improved safety and reduced maintenance costs |

By studying these case studies, professionals in the field of pipeline engineering can gain a deeper understanding of the complexities involved and develop more effective strategies for future projects.

Future Trends in Pipeline Engineering

Pipeline engineering is on the cusp of a revolution, driven by emerging technologies and the need for sustainable energy. As the world grapples with the challenges of climate change and energy security, the pipeline engineering sector is poised to play a critical role in the transition to a more sustainable future.

The Role of Sustainable Energy

The shift towards sustainable energy is a significant driver of change in pipeline engineering. As the world moves away from fossil fuels, pipelines will be repurposed or redesigned to accommodate new energy sources such as hydrogen and biofuels. This transition requires innovative solutions to ensure the safe and efficient transport of these alternative energies.

The integration of sustainable energy sources into the existing pipeline infrastructure will necessitate advancements in material science and pipeline design. For instance, pipelines may need to be coated with specialized materials to prevent corrosion when transporting hydrogen.

Emerging Technologies and Their Impact

Emerging technologies such as smart pipelines, IoT sensors, and advanced data analytics are transforming the pipeline engineering landscape. These technologies enable real-time monitoring and predictive maintenance, reducing the risk of pipeline failures and enhancing operational efficiency.

- Smart pipelines equipped with sensors can detect anomalies and predict potential failures.

- Advanced data analytics can optimize pipeline operations, reducing energy consumption and costs.

- IoT technologies facilitate real-time monitoring, enabling swift responses to operational issues.

Future Challenges in Pipeline Engineering

Despite the advancements, the pipeline engineering sector will face numerous challenges in the future. These include managing the transition to sustainable energy, mitigating the environmental impact of pipeline operations, and addressing cybersecurity risks associated with the adoption of emerging technologies.

To overcome these challenges, professionals in the field must stay abreast of the latest developments and be prepared to adapt to changing circumstances. This will require ongoing education and training, as well as a commitment to innovation and sustainability.

Education and Career Paths in Pipeline Engineering

Education and career development are intertwined in the field of pipeline engineering, offering numerous pathways for aspiring engineers. To succeed in this complex field, individuals must navigate through the right educational channels and understand the various career opportunities available.

Relevant Degrees and Certifications

A career in pipeline engineering typically begins with a relevant educational background. Degrees in engineering disciplines such as mechanical, civil, or chemical engineering are highly valued. Additionally, specialized courses or certifications in pipeline engineering can provide a competitive edge.

Some of the key certifications include:

- Certified Pipeline Engineer (CPE)

- Professional Engineer (PE) license

- Certified in Pipeline Integrity (CPI)

These certifications demonstrate expertise and commitment to the field, enhancing job prospects.

Skills Required in the Field

Pipeline engineers require a diverse set of skills, including technical knowledge, problem-solving abilities, and effective communication. Proficiency in software tools such as CAESAR II for stress analysis and Autodesk Civil 3D for design is crucial.

| Skill | Description | Importance Level |

|---|---|---|

| Technical Knowledge | Understanding of engineering principles and pipeline design | High |

| Problem-Solving | Ability to analyze and resolve complex engineering problems | High |

| Communication | Effective communication of designs, plans, and issues to stakeholders | Medium |

| Software Proficiency | Proficiency in engineering software such as CAESAR II and Autodesk Civil 3D | High |

Job Opportunities and Growth

The demand for pipeline engineers is driven by the need for energy infrastructure development and maintenance. Job opportunities exist in various sectors, including oil and gas, water management, and industrial construction.

For those starting their careers, entry-level positions in civil engineering can provide a stepping stone into pipeline engineering. Career growth can be achieved through experience, further education, and obtaining relevant certifications.

As the energy sector continues to evolve, the role of pipeline engineers will remain critical, offering a promising career path for those with the right education and skills.

Conclusion

Pipeline engineering is a complex and multifaceted field that plays a crucial role in the global energy infrastructure. As we have explored throughout this article, it encompasses a wide range of disciplines, from design and construction to maintenance and inspection.

Key Takeaways

The key principles of pipeline engineering, including fluid mechanics, material selection, and stress analysis, form the foundation of this field. Understanding the different types of pipelines, such as oil and gas, water and sewer, and industrial pipelines, is also essential.

Shaping the Future

As the world shifts towards sustainable energy sources, pipeline engineering will continue to evolve. Emerging technologies, such as smart pipeline technologies and automation, will play a significant role in shaping the future of this field. Aspiring engineers can contribute to this evolution by pursuing careers in pipeline engineering.

Career Opportunities

With the increasing demand for energy and infrastructure development, pipeline engineering offers a promising career path. By acquiring the necessary skills and knowledge, individuals can embark on a rewarding journey in this vital field.