The design of modern engines relies heavily on advanced materials that can withstand extreme conditions. The field of materials science and engineering plays a crucial role in developing engines that are not only efficient but also durable.

The use of ceramic, metallurgical, and polymer engine materials has revolutionized engine technology, offering improved performance and reduced environmental impact. Understanding the properties and applications of these materials is essential for engineers to design better engines.

Key Takeaways

- The importance of materials science in modern engine design.

- Overview of ceramic, metallurgical, and polymer engine materials.

- The role of advanced materials in improving engine efficiency.

- Applications of different materials in engine technology.

- The impact of materials science on reducing environmental footprint.

The Evolution of Materials Science in Engine Technology

Engine technology has witnessed significant transformations, largely driven by innovations in materials science. The historical development of engine materials has been a crucial factor in this evolution.

Historical Development of Engine Materials

The history of engine materials dates back to the early 20th century when the first internal combustion engines were developed. Initially, materials such as cast iron and steel were predominantly used due to their strength and durability. As engine technology advanced, so did the materials used, with the introduction of aluminum alloys and titanium, which offered reduced weight and improved thermal properties.

| Material | Properties | Application |

|---|---|---|

| Cast Iron | High strength, durability | Early engine blocks |

| Aluminum Alloys | Lightweight, good thermal conductivity | Modern engine blocks, cylinder heads |

| Titanium | High strength-to-weight ratio, corrosion resistance | High-performance engine components |

Modern Challenges Driving Materials Innovation

Today, engine materials face modern challenges such as the need for higher efficiency, reduced emissions, and improved durability. Materials innovation is critical to addressing these challenges. Advanced materials like ceramics and superalloys are being developed to withstand extreme temperatures and stresses, thereby enhancing engine performance and reducing environmental impact.

The future of engine technology is closely tied to advancements in materials science and engineering. As research continues, we can expect to see even more sophisticated materials being used in engine design, leading to more efficient, powerful, and environmentally friendly engines.

Fundamental Principles of Materials Science and Engineering

Materials science and engineering form the backbone of innovations in engine design and performance. The intricate relationship between a material’s structure and its properties is a foundational principle that guides the selection and development of materials for engine applications.

Structure-Property Relationships

The performance of engine components is heavily influenced by the structure-property relationships of the materials used. This means that the atomic and microstructural arrangement of a material dictates its mechanical, thermal, and electrical properties. For instance, the strength and durability of alloys are directly related to their composition and heat treatment processes. Understanding these relationships is crucial for tailoring materials to meet specific engine requirements.

Material Selection Criteria for Engine Applications

Selecting the right material for engine components involves considering several critical factors, including mechanical strength, thermal resistance, corrosion resistance, and cost-effectiveness. Engine materials must withstand extreme conditions such as high temperatures, corrosive environments, and significant mechanical stress. The selection process often involves balancing these factors to achieve optimal performance and longevity.

Performance Requirements in Extreme Conditions

Engine materials are subjected to extreme conditions, including high temperatures, high stresses, and corrosive environments. The ability of a material to perform under these conditions is paramount. For example, turbine blades in jet engines are made from materials that can withstand extremely high temperatures without losing their structural integrity. Meeting these performance requirements is essential for ensuring engine efficiency, reliability, and safety.

By understanding and applying the fundamental principles of materials science and engineering, engineers can develop materials that enhance engine performance, efficiency, and durability. This knowledge is critical for advancing engine technology and meeting the demands of modern applications.

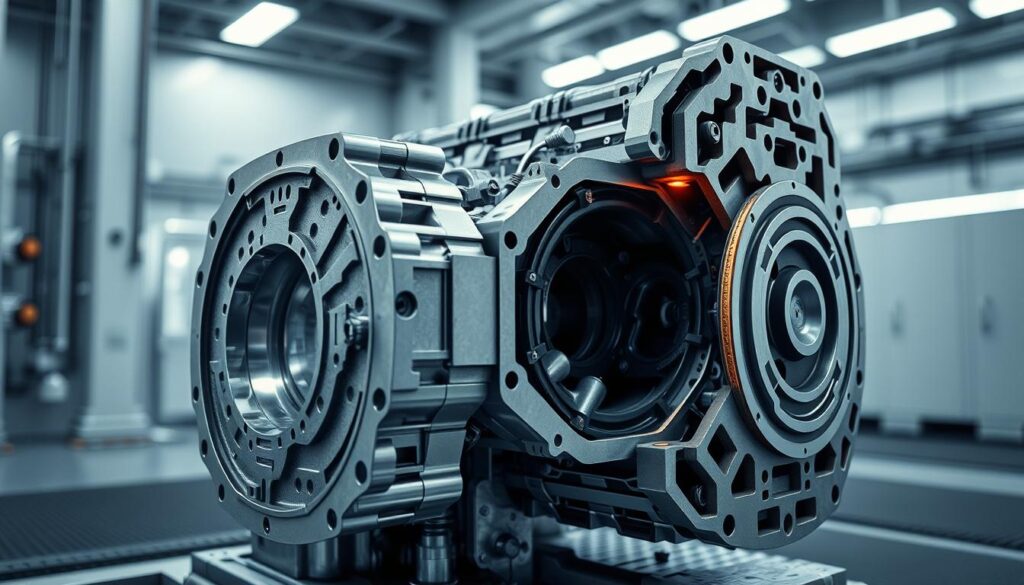

Ceramic Materials in Engine Design

Engine design has seen a paradigm shift with the advent of ceramic materials, known for their exceptional properties. Ceramic materials are increasingly being utilized in engine components due to their ability to withstand extreme conditions.

Properties and Advantages of Engineering Ceramics

Engineering ceramics offer several advantages, including high thermal resistance, mechanical strength, and corrosion resistance. These properties make them ideal for use in harsh environments.

Thermal Resistance Characteristics

Ceramic materials exhibit excellent thermal resistance, allowing them to maintain their structure and performance even at high temperatures. This characteristic is crucial for engine components exposed to extreme heat.

Mechanical Strength Considerations

In addition to thermal resistance, engineering ceramics also possess high mechanical strength, enabling them to withstand the stresses and strains within an engine. This strength is vital for ensuring the durability and reliability of engine components.

Ceramic Engine Components and Applications

Ceramic materials are used in various engine components, such as piston heads, cylinder liners, and valves. Their use in these components enhances engine performance, efficiency, and longevity.

- Ceramic piston heads improve thermal efficiency.

- Ceramic cylinder liners reduce wear and tear.

- Ceramic valves offer improved corrosion resistance.

Manufacturing Challenges and Solutions

Despite their advantages, the manufacture of ceramic engine components poses several challenges, including high production costs and the risk of material defects. Advanced manufacturing techniques and quality control measures are being implemented to address these challenges.

By understanding the properties and applications of ceramic materials, engineers can design more efficient and durable engines. The continued development of ceramic materials and manufacturing processes will be crucial for advancing engine technology.

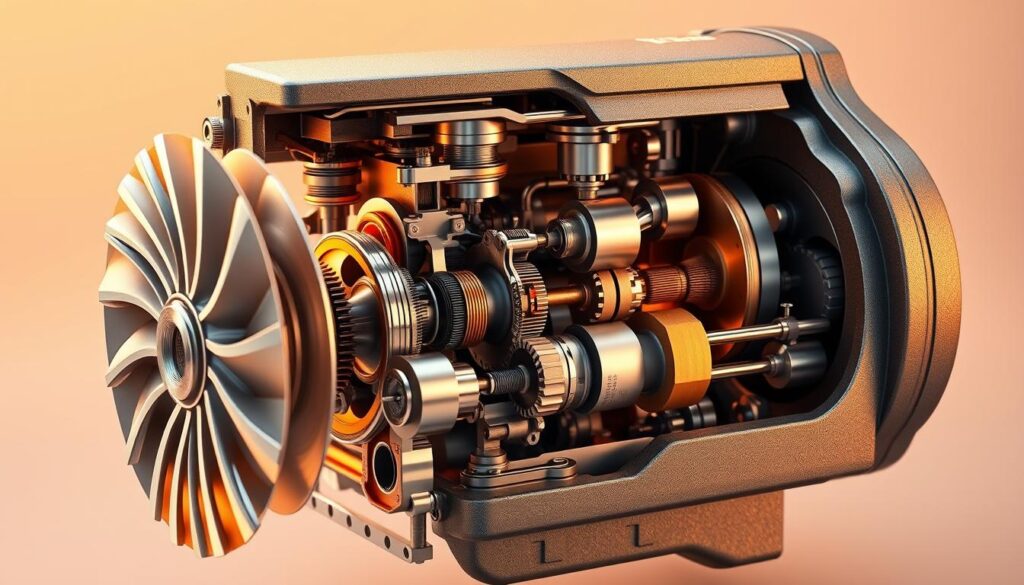

Metallurgical Materials Science and Engineering

Metallurgical materials science is at the forefront of engine innovation, enabling the creation of more efficient and powerful engines. The development and application of advanced metallurgical materials are crucial for meeting the demanding requirements of modern engine designs. These materials must withstand extreme temperatures, corrosive environments, and significant mechanical stress.

Advanced Alloys for Engine Applications

Advanced alloys are critical in engine design due to their enhanced properties, such as high strength, resistance to corrosion, and ability to withstand extreme temperatures.

High-Temperature Superalloys

High-temperature superalloys are used in engine components that are exposed to extreme heat, such as turbine blades. These alloys maintain their strength and resist degradation even at temperatures above 1000°C.

Lightweight Aluminum and Titanium Alloys

Lightweight alloys, such as those made from aluminum and titanium, are used to reduce engine weight while maintaining strength. This results in improved fuel efficiency and reduced emissions.

Heat Treatment and Surface Engineering

Heat treatment and surface engineering are processes used to enhance the properties of metallurgical materials. Heat treatment involves heating and cooling metals to achieve desired properties, while surface engineering modifies the surface of materials to improve wear resistance and corrosion resistance.

Corrosion Resistance and Durability

Corrosion resistance and durability are critical factors in the selection of metallurgical materials for engine applications. Materials must be able to withstand harsh environments without degrading over time.

Polymer Materials Science and Engineering

Polymer materials science plays a crucial role in advancing engine technology, providing innovative materials that enhance performance and efficiency. The development and application of high-performance polymers have become increasingly important in engine design.

High-Performance Polymers for Engine Components

High-performance polymers are engineered to meet the demanding requirements of engine components, offering superior strength, durability, and resistance to extreme temperatures and chemicals. These polymers are used in various engine parts, including seals, gaskets, and other critical components.

Thermoplastics vs. Thermosets in Engine Applications

Thermoplastics and thermosets are two categories of polymers used in engine applications. Thermoplastics can be melted and reformed multiple times, making them suitable for applications requiring flexibility and recyclability. In contrast, thermosets are irreversibly cured, providing excellent thermal stability and resistance to deformation under load.

Polymer Composites and Blends

Polymer composites and blends are designed to combine the beneficial properties of different materials, enhancing overall performance. These materials offer improved strength, toughness, and resistance to environmental factors, making them ideal for demanding engine applications.

Thermal Stability and Chemical Resistance

One of the critical advantages of high-performance polymers is their ability to maintain their properties under extreme temperatures and in the presence of aggressive chemicals. This thermal stability and chemical resistance are crucial for ensuring the longevity and reliability of engine components.

Weight Reduction and Efficiency Benefits

The use of polymer materials in engine design contributes significantly to weight reduction, which is a key factor in improving fuel efficiency and reducing emissions. By replacing traditional metal components with lightweight polymers, engines can achieve better performance and lower operational costs.

| Material | Thermal Stability | Chemical Resistance | Weight Reduction |

|---|---|---|---|

| Thermoplastics | Good | Excellent | High |

| Thermosets | Excellent | Good | Moderate |

| Polymer Composites | Excellent | Excellent | High |

Materials Science and Engineering: Ceramic, Metallurgical, and Polymer Engine Applications

Engine applications demand a deep understanding of materials science and engineering to optimize ceramic, metallurgical, and polymer materials. The selection and development of materials for engine components are critical for achieving desired performance, efficiency, and durability.

Comparative Analysis of Material Properties

A comparative analysis of ceramic, metallurgical, and polymer materials reveals distinct advantages and limitations for engine applications. Ceramics offer high thermal resistance and hardness, making them suitable for high-temperature components. Metallurgical materials, such as advanced alloys, provide excellent strength and durability. Polymers, while generally less robust, offer benefits in terms of weight reduction and corrosion resistance.

- Ceramics: High thermal resistance, hardness

- Metallurgical materials: Strength, durability

- Polymers: Weight reduction, corrosion resistance

Material Selection Strategies for Specific Engine Components

Selecting the appropriate material for specific engine components involves considering factors such as operating temperature, mechanical stress, and environmental conditions. For instance, ceramic materials are often used in engine components exposed to high temperatures, while metallurgical materials are preferred for structural components requiring high strength.

Key considerations for material selection include:

- Operating temperature and thermal stability

- Mechanical stress and durability

- Environmental conditions and corrosion resistance

Hybrid Material Systems and Solutions

Hybrid material systems, which combine different materials to achieve enhanced properties, are becoming increasingly important in engine design. By integrating materials such as ceramics and metals, engineers can create components that leverage the benefits of each material, leading to improved performance and efficiency.

For example, hybrid ceramic-metal composites can offer both high thermal resistance and mechanical strength, making them ideal for advanced engine applications.

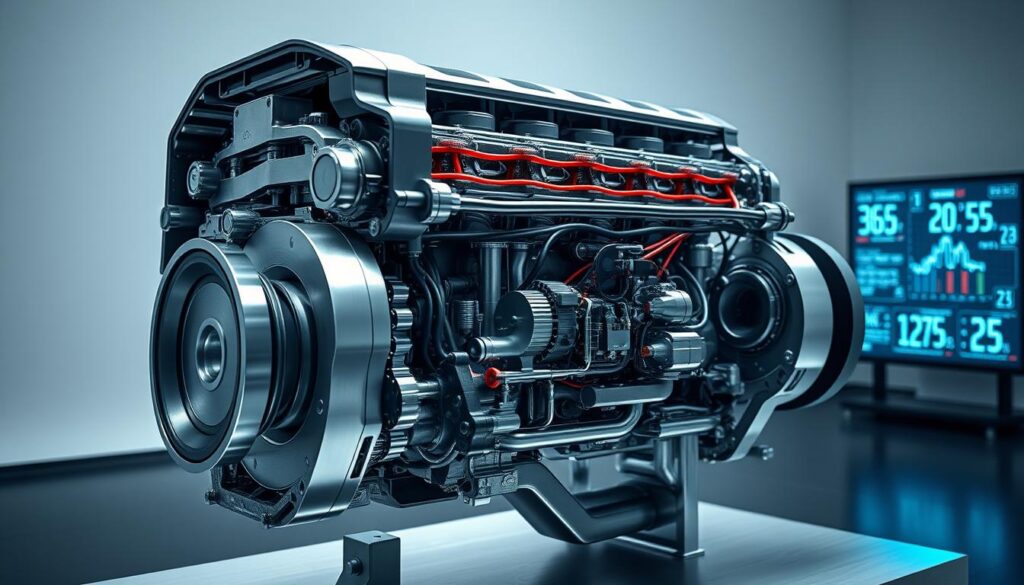

Composite Materials Technology in Engine Design

Composite materials are transforming engine technology by offering enhanced strength, reduced weight, and improved durability. These materials are engineered to meet the demanding requirements of modern engines, providing significant advantages over traditional materials.

The use of composite materials in engine design allows for the creation of complex geometries and structures that cannot be achieved with conventional materials. This flexibility enables engineers to optimize engine performance, reduce weight, and enhance fuel efficiency.

Metal Matrix Composites

Metal Matrix Composites (MMCs) combine the benefits of metals with the enhanced properties of ceramic or carbon reinforcements. MMCs offer improved thermal stability, wear resistance, and mechanical strength, making them ideal for high-temperature engine components.

Ceramic Matrix Composites

Ceramic Matrix Composites (CMCs) are designed for extreme environments, providing excellent thermal shock resistance and high-temperature stability. CMCs are used in engine components that are exposed to high temperatures, such as turbine blades and combustor liners.

Polymer Matrix Composites

Polymer Matrix Composites (PMCs) are lightweight and offer high specific strength and stiffness. PMCs are used in engine components where weight reduction is critical, such as in intake manifolds and engine mounts.

| Composite Material | Key Properties | Engine Applications |

|---|---|---|

| Metal Matrix Composites | High thermal stability, wear resistance | Pistons, cylinder liners |

| Ceramic Matrix Composites | Thermal shock resistance, high-temperature stability | Turbine blades, combustor liners |

| Polymer Matrix Composites | Lightweight, high specific strength | Intake manifolds, engine mounts |

The integration of composite materials in engine design is a significant step forward in achieving more efficient, powerful, and environmentally friendly engines. By leveraging the unique properties of different composite materials, engineers can create engines that meet the demands of modern applications.

Materials Characterization and Testing Methods

The performance and reliability of engine components depend on the thorough characterization and testing of materials used in their manufacture. Materials characterization is a critical step in understanding material properties, which in turn, informs the design and optimization of engine components.

Mechanical Testing Techniques

Mechanical testing is essential for evaluating the strength, durability, and performance of materials under various conditions. This includes assessing how materials respond to different types of loading.

Tensile, Compression, and Fatigue Testing

Tensile testing measures a material’s resistance to breaking under tension, while compression testing evaluates its behavior under compressive forces. Fatigue testing, on the other hand, assesses a material’s endurance under cyclic loading conditions. As noted by a renowned materials scientist, “The ability of a material to withstand fatigue is crucial for its application in cyclic loading environments.”

High-Temperature Performance Evaluation

High-temperature performance evaluation is critical for materials used in engine components, which are often exposed to extreme temperatures. This testing helps in understanding how materials behave under thermal stress, ensuring their reliability in operational conditions.

Thermal and Chemical Analysis

Thermal analysis involves studying the properties of materials as they change with temperature. Techniques such as Differential Scanning Calorimetry (DSC) and Thermogravimetry (TGA) provide insights into thermal stability and degradation patterns. Chemical analysis, including techniques like X-Ray Fluorescence (XRF) and Fourier Transform Infrared Spectroscopy (FTIR), helps in understanding the chemical composition and potential reactivity of materials.

“The thermal and chemical stability of materials is paramount for their application in harsh engine environments.”

Microstructural Characterization

Microstructural characterization is vital for understanding the internal structure of materials, which influences their properties. Techniques such as Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) provide detailed images of the microstructure, helping in the assessment of material quality and potential performance.

By employing these characterization and testing methods, engineers can ensure that materials used in engine components meet the required standards for performance, safety, and durability.

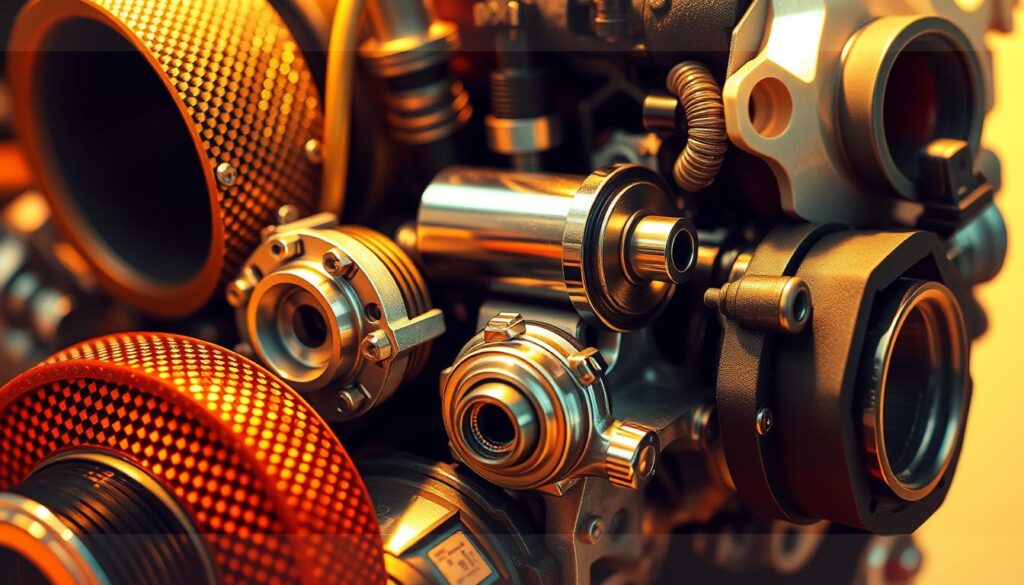

Advanced Materials Processing Techniques

Advanced materials processing techniques are transforming the manufacturing landscape for engine components. These innovations enable the production of complex geometries, improved material properties, and enhanced performance characteristics.

Additive Manufacturing for Engine Components

Additive manufacturing, also known as 3D printing, allows for the creation of intricate engine components with complex geometries that cannot be produced through traditional manufacturing methods. This technique enables the production of lightweight components, reduces material waste, and can lead to improved engine efficiency.

Precision Machining and Forming

Precision machining and forming techniques are critical for producing engine components with high accuracy and surface finish. These methods ensure that components meet stringent tolerances and performance requirements, contributing to overall engine reliability and performance.

Surface Treatment Technologies

Surface treatment technologies, such as coating and nitriding, enhance the durability and performance of engine components. These treatments can improve wear resistance, reduce friction, and protect against corrosion, thereby extending the lifespan of engine parts.

| Technique | Benefits | Applications |

|---|---|---|

| Additive Manufacturing | Complex geometries, reduced material waste | Lightweight engine components |

| Precision Machining | High accuracy, improved surface finish | Engine components requiring tight tolerances |

| Surface Treatment | Enhanced durability, improved wear resistance | Engine components subject to high stress and wear |

The integration of these advanced materials processing techniques is pivotal for the development of next-generation engine technologies. By leveraging these innovations, manufacturers can achieve significant improvements in engine performance, efficiency, and reliability.

Materials Science for Engine Performance Optimization

Materials science is at the forefront of enhancing engine performance through innovative material solutions. By developing materials with specific properties, engineers can significantly improve engine efficiency, reduce energy losses, and enhance overall performance.

The role of materials science in engine performance optimization is multifaceted, involving improvements in thermal efficiency, friction reduction, and durability enhancement. Each of these areas is critical to achieving better engine performance and reducing environmental impact.

Thermal Efficiency Improvements

Thermal efficiency is a key factor in engine performance, directly affecting fuel consumption and emissions. Advanced materials with high thermal resistance and conductivity can improve heat management within the engine, leading to better thermal efficiency.

For instance, ceramic materials are being used in engine components due to their excellent thermal properties. Ceramic matrix composites, in particular, offer high thermal stability and resistance to degradation at high temperatures.

| Material | Thermal Conductivity (W/mK) | Max Operating Temperature (°C) |

|---|---|---|

| Ceramic Matrix Composites | 20-40 | 1200-1500 |

| Advanced Alloys | 10-30 | 800-1200 |

Friction Reduction Strategies

Friction within engine components can lead to significant energy losses. Materials science plays a crucial role in reducing friction through the development of low-friction coatings and advanced lubricants.

For example, the application of diamond-like carbon (DLC) coatings on engine parts can significantly reduce friction, improving fuel efficiency and reducing wear on components.

Durability and Lifespan Enhancement

Enhancing the durability of engine components is vital for prolonging engine lifespan and reducing maintenance costs. Materials with improved strength, corrosion resistance, and fatigue properties contribute to more durable engines.

Advanced materials and manufacturing techniques, such as additive manufacturing, enable the production of complex geometries and structures that can enhance component durability.

Nanotechnology in Engine Materials Development

Nanotechnology is playing a crucial role in advancing engine materials, offering unprecedented improvements in performance and durability. By manipulating materials at the nanoscale, researchers can create novel materials with unique properties that are not achievable through traditional methods.

Nanomaterials and Nanocomposites

Nanomaterials, including nanoparticles and nanotubes, exhibit enhanced mechanical, thermal, and electrical properties compared to their bulk counterparts. When integrated into composites, these nanomaterials can significantly improve the overall performance of the material. For instance, nanocomposites can be designed to have enhanced strength, toughness, and resistance to wear and corrosion.

As noted by a leading researcher, “The use of nanomaterials in composites is a game-changer for engine materials, enabling the creation of components that are both stronger and lighter.” This highlights the potential of nanotechnology to transform engine design and performance.

Applications in Engine Component Design

The application of nanotechnology in engine component design is vast and varied. Nanomaterials and nanocomposites are being used to develop advanced engine components, such as cylinder liners, piston rings, and fuel injectors, that offer improved performance and efficiency. For example, nano-ceramic coatings can be applied to engine components to reduce friction and enhance durability.

The use of nanotechnology in engine materials development is expected to continue growing, driven by the need for more efficient, sustainable, and powerful engines. As researchers continue to explore the potential of nanomaterials and nanocomposites, we can expect to see significant advancements in engine technology.

Sustainable Materials Solutions for Engine Design

As the world shifts towards more environmentally friendly technologies, the role of sustainable materials in engine design becomes increasingly crucial. The engine, being a critical component of various machines and vehicles, has a significant impact on the environment, primarily due to the materials used in its construction.

The need for sustainable materials in engine design is driven by the desire to reduce the environmental footprint of engines throughout their lifecycle, from production to disposal. This involves the use of eco-friendly materials that are not only less harmful to the environment but also offer improved performance and efficiency.

Eco-friendly Material Alternatives

The development of eco-friendly material alternatives is a key aspect of sustainable engine design. Some of the promising materials include:

- Recycled metals and alloys that reduce the need for primary material extraction.

- Bio-based composites that offer a sustainable alternative to traditional composite materials.

- Advanced ceramics that provide improved thermal efficiency and durability.

Lifecycle Assessment and Recyclability

A crucial aspect of sustainable materials is their lifecycle assessment and recyclability. Conducting a thorough lifecycle assessment helps in understanding the environmental impacts associated with the material, from production to end-of-life disposal or recycling.

Improving recyclability is also vital, as it enables the recovery of valuable materials, reduces waste, and decreases the demand for primary materials. Engine designers and manufacturers are now focusing on designing engines with recyclability in mind, using materials that can be easily recycled or reused.

Some key strategies for enhancing lifecycle assessment and recyclability include:

- Designing engine components with disassembly and recycling in mind.

- Using materials with high recyclability and minimal environmental impact.

- Implementing take-back programs for used engine components to facilitate recycling.

Materials Science Software and Simulation Tools

The integration of computational materials science into engine design has opened new avenues for innovation. By leveraging advanced software and simulation tools, engineers can now predict material behavior, optimize properties, and streamline the development process.

Computational materials science is at the forefront of this revolution, enabling the simulation of material properties and behavior under various conditions. This field combines theoretical knowledge with computational methods to predict how materials will perform in real-world applications.

Computational Materials Science

Computational materials science involves the use of algorithms and computational models to understand material properties. Advanced simulation tools allow researchers to model complex material behaviors, reducing the need for physical prototypes and accelerating the development cycle.

As noted by experts, “The use of computational models in materials science has transformed the way we design and optimize materials for specific applications.” This shift towards computational methods has significantly impacted the field, enabling more precise and efficient material design.

Predictive Modeling for Material Performance

Predictive modeling is a critical component of materials science software, enabling engineers to forecast how materials will perform under different conditions. By using predictive modeling techniques, researchers can identify the most promising materials for specific applications and optimize their properties.

The combination of computational materials science and predictive modeling has the potential to revolutionize engine design. By accurately predicting material behavior, engineers can create more efficient, durable, and high-performance engines.

Case Studies: Materials Innovation in Modern Engines

Innovations in materials science have significantly impacted the design and functionality of contemporary engines. The relentless pursuit of efficiency, performance, and sustainability has driven the development of new materials and technologies. This section highlights case studies that demonstrate the successful application of materials innovation in modern engines across various industries.

Automotive Engine Applications

The automotive industry has seen significant advancements with the introduction of advanced materials. For instance, the use of aluminum alloys and high-strength steel has enabled the production of lighter, more fuel-efficient vehicles. Additionally, the incorporation of ceramic components in engine parts has improved thermal efficiency and reduced emissions.

- Improved fuel efficiency through lightweight materials

- Enhanced thermal efficiency with ceramic components

- Reduced emissions due to advanced material properties

Aerospace Engine Advancements

Aerospace engines have benefited greatly from materials innovation, with advancements in superalloys and ceramic matrix composites. These materials have enabled engines to operate at higher temperatures, improving efficiency and reducing fuel consumption. For example, the use of single-crystal superalloys in turbine blades has significantly enhanced engine performance and durability.

- Higher operating temperatures with superalloys

- Improved efficiency with ceramic matrix composites

- Enhanced durability through single-crystal superalloys

Industrial Power Generation Systems

Industrial power generation has also seen significant improvements with the adoption of advanced materials. The use of advanced steel alloys and coatings has enhanced the durability and efficiency of power generation equipment. For instance, thermal barrier coatings have improved the thermal efficiency of gas turbines, leading to reduced fuel consumption and emissions.

As stated by a leading expert, “The development and application of new materials are crucial for the future of power generation, enabling more efficient and sustainable energy production.”

“The future of energy production relies heavily on the innovation and application of advanced materials.”

Challenges and Future Trends in Engine Materials Science

Engine materials science faces a myriad of challenges, from technical limitations to economic barriers, that must be overcome to achieve future breakthroughs. The development of materials that can withstand the extreme conditions within modern engines is a complex task, requiring a deep understanding of materials science and engineering principles.

Technical Limitations and Economic Barriers

One of the primary challenges in engine materials science is the technical limitation of current materials. Many materials used in engine construction are pushed to their limits by the extreme temperatures, stresses, and corrosive environments found within engines. For instance, turbine blades in jet engines are subjected to temperatures that can exceed 1,500°C, necessitating the development of advanced cooling systems and high-temperature-resistant materials.

Economic barriers also play a significant role in the development and implementation of new engine materials. The cost of producing advanced materials, such as high-temperature ceramics and superalloys, can be prohibitively expensive, limiting their widespread adoption. Furthermore, the development of new materials often requires significant investment in research and development, as well as the creation of new manufacturing processes.

Key technical limitations include:

- High-temperature resistance

- Corrosion resistance

- Mechanical strength and durability

Emerging Materials and Research Directions

Despite these challenges, researchers are actively exploring new materials and technologies that promise to revolutionize engine design. Advanced composites, nanomaterials, and smart materials are being investigated for their potential to enhance engine performance, efficiency, and durability.

Some of the emerging research directions include:

- The development of ceramic matrix composites (CMCs) for high-temperature applications

- The use of nanomaterials to enhance mechanical properties and thermal resistance

- The integration of smart materials that can adapt to changing engine conditions

These emerging materials and research directions hold significant promise for overcoming the current challenges in engine materials science and enabling the development of more efficient, powerful, and sustainable engines.

Conclusion: The Integral Role of Materials Science in Engine Innovation

Materials science plays a vital role in driving engine innovation, enabling the development of more efficient, durable, and sustainable engines. Throughout this article, we have explored the various aspects of materials science and their applications in ceramic, metallurgical, and polymer engine design.

The evolution of materials science has led to significant advancements in engine technology, from the development of advanced ceramics and alloys to the use of high-performance polymers. By understanding the fundamental principles of materials science and engineering, researchers and engineers can design and optimize engine components for improved performance and reduced environmental impact.

The integration of materials science and engine innovation has the potential to transform the future of engine design, enabling the creation of more efficient, sustainable, and reliable engines. As research continues to advance, we can expect to see new materials and technologies emerge, further driving innovation in the field.