What if the products we use every day could be made stronger, lighter, and more sustainable? This is the question that material engineers are working to answer.

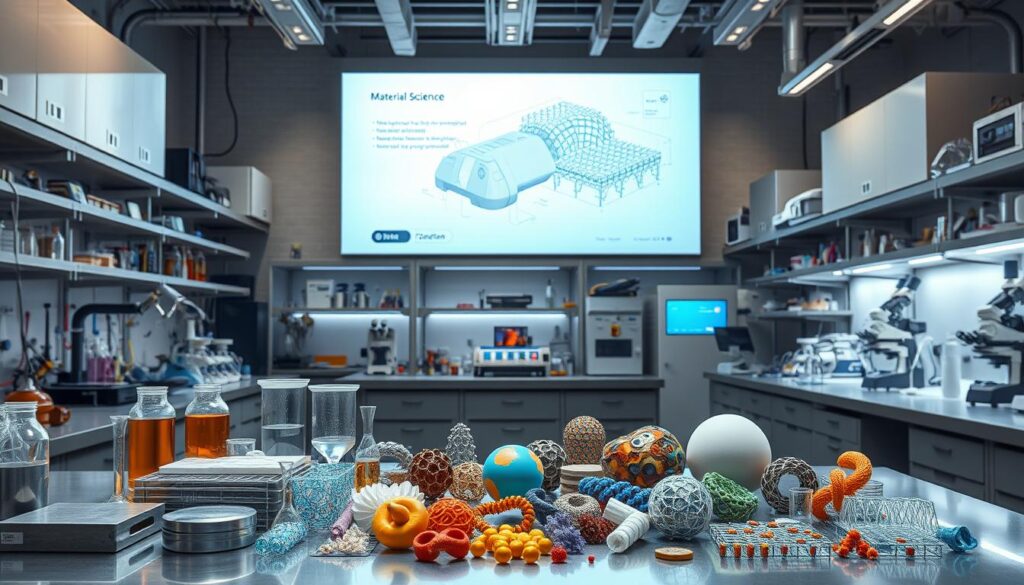

Advances in materials science are revolutionizing various industries, from aerospace to healthcare. By designing and developing innovative materials, engineers are creating new possibilities for product design and functionality.

The impact of material engineering is evident in our daily lives, from the smartphones we use to the medical devices that save lives. As research continues to advance, we can expect to see even more exciting developments in this field.

Key Takeaways

- Material engineers are working to create stronger, lighter, and more sustainable products.

- Advances in materials science are driving innovation in various industries.

- The impact of material engineering is evident in our daily lives.

- Research in this field is expected to lead to more exciting developments.

- Material engineering is shaping the future of product design and functionality.

What is Material Engineering?

The study of material engineering encompasses a broad range of disciplines, including metallurgy, polymer engineering, and materials research. This interdisciplinary field focuses on understanding the properties and applications of various materials, such as metals, polymers, ceramics, and composites, to develop new products and technologies.

Definition and Overview

Material engineering is defined as the study and application of materials to create innovative solutions for various industries. It involves understanding the structure, properties, and performance of materials to design and develop new products. The field is closely related to other engineering disciplines, such as mechanical engineering, electrical engineering, and civil engineering.

Material engineers work with a wide range of materials, from traditional metals and alloys to advanced polymers and composites. They use various techniques, including experimentation, simulation, and modeling, to understand material behavior and optimize their properties.

The Importance in Modern Industry

The importance of material engineering in modern industry cannot be overstated. It enables the creation of innovative materials and solutions that drive technological advancements. Material engineers play a crucial role in developing sustainable and high-performance materials that meet the needs of various industries, from aerospace and automotive to electronics and construction.

By understanding the properties and applications of different materials, material engineers can help reduce costs, improve efficiency, and enhance product performance. For example, the development of lightweight composites has revolutionized the aerospace industry, while advances in semiconductor materials have enabled the creation of smaller, faster, and more powerful electronics.

Historical Development of Material Engineering

Material engineering has a storied past, with milestones that have transformed the field forever. The evolution of materials science has been pivotal in shaping human history, from the Stone Age to the Silicon Age.

Key Milestones in Material Science

The journey of material science is marked by significant discoveries that have revolutionized industries. One of the earliest milestones was the discovery of metals, which led to the Bronze Age and Iron Age, significantly impacting human civilization.

The 20th century saw the advent of nanomaterials and advanced composites, which have been crucial in modern technological advancements. The development of semiconductors was instrumental in the electronics industry.

| Period | Material/Discovery | Impact |

|---|---|---|

| Stone Age | Stone tools | Early human tools and weapons |

| Bronze Age | Copper and Tin alloys | Advancements in weaponry and tools |

| Iron Age | Iron and Steel | Revolutionized agriculture and warfare |

| 20th Century | Nanomaterials and Composites | Modern technological advancements |

Innovations that Changed the Field

Innovations in structural materials have enabled the construction of high-rise buildings, aircraft, and spacecraft. The development of advanced composites has been critical in the aerospace industry.

The future of material engineering is bright, with ongoing research in nanomaterials and smart materials promising to bring about the next wave of technological advancements.

Types of Materials in Engineering

The versatility of material engineering stems from its involvement with a broad spectrum of materials, each suited to specific uses. Material engineers work with a wide range of materials, including metals, polymers, ceramics, and composites, to develop innovative solutions that cater to various industries.

Metals and Alloys

Metals and alloys are fundamental materials in engineering, known for their strength, durability, and versatility. Metallurgy, the science of metals, plays a crucial role in developing new alloys with enhanced properties. For instance, steel alloys are widely used in construction due to their high strength and resistance to corrosion.

The properties of metals and alloys can be tailored through various processes such as alloying, heat treatment, and cold working. This allows material engineers to select the most appropriate metal or alloy for specific applications, ranging from aerospace to automotive industries.

Polymers and Composites

Polymer engineering has revolutionized many industries by providing materials that are lightweight, corrosion-resistant, and can be engineered to have specific properties. Polymers are used in a wide range of applications, from packaging materials to biomedical devices.

Composites, which combine different materials to achieve superior properties, are also gaining prominence. For example, carbon fiber reinforced polymers (CFRP) are used in aerospace and sports equipment due to their high strength-to-weight ratio.

Ceramics and Glass

Ceramic engineering involves the development and application of ceramic materials, which are known for their hardness, thermal stability, and resistance to corrosion. Ceramics are used in various applications, including cookware, dental implants, and advanced electronics.

Glass, another important material, is valued for its transparency, chemical resistance, and ability to be formulated with specific properties. Advances in glass technology have led to its use in displays, optical fibers, and architectural glazing.

| Material Type | Key Properties | Common Applications |

|---|---|---|

| Metals and Alloys | High strength, durability | Aerospace, automotive, construction |

| Polymers and Composites | Lightweight, corrosion-resistant | Packaging, biomedical devices, aerospace |

| Ceramics and Glass | Hardness, thermal stability | Cookware, dental implants, electronics, displays |

The Role of Material Engineers

Material engineers play a crucial role in shaping the modern world by designing and analyzing materials for various applications. Their work is fundamental to advancements in technology, infrastructure, and consumer products.

Responsibilities and Daily Tasks

Material engineers are responsible for a wide range of tasks, including:

- Designing and developing new materials with specific properties.

- Testing materials to determine their suitability for different applications.

- Analyzing the performance of materials under various conditions.

- Collaborating with other engineers and scientists to integrate materials into products.

The daily tasks of material engineers often involve using advanced equipment and software to analyze materials and simulate their behavior under different conditions. This requires a strong foundation in materials science and the ability to apply theoretical knowledge to practical problems.

Skills Required for Success

To succeed in their roles, material engineers need a combination of technical skills, including:

- A deep understanding of materials science and the properties of different materials.

- Analytical skills to interpret data from material tests and simulations.

- Problem-solving skills to address challenges in material development and application.

- Collaboration and communication skills to work effectively with cross-functional teams.

Additionally, material engineers must stay up-to-date with the latest developments in materials research and technologies, adapting their skills and knowledge to meet evolving demands.

Applications of Material Engineering

Material engineering plays a crucial role in the development of new products and solutions that shape modern industry. The applications of material engineering are diverse, ranging from automotive to construction industries.

Aerospace and Automotive Industries

The aerospace and automotive industries rely heavily on advanced materials to improve performance, safety, and efficiency. Composites technology has been instrumental in creating lightweight yet strong components for aircraft and vehicles.

For instance, carbon fiber reinforced polymers (CFRP) are widely used in the aerospace industry for their high strength-to-weight ratio. Similarly, in the automotive sector, the use of advanced high-strength steel and aluminum alloys has enabled the production of lighter, more fuel-efficient vehicles.

Electronics and Nanotechnology

In the electronics industry, material engineering has led to the development of nanomaterials with unique properties. These materials are used in the production of smaller, faster, and more efficient electronic devices.

Nanotechnology, in particular, has opened up new avenues for innovation in electronics, enabling the creation of nanoscale components that are crucial for the next generation of electronic devices.

Construction and Infrastructure

The construction industry benefits significantly from advancements in structural materials. New materials and technologies have improved the durability, sustainability, and safety of buildings and infrastructure.

| Industry | Material | Application |

|---|---|---|

| Aerospace | Carbon Fiber Composites | Aircraft Structures |

| Automotive | Advanced High-Strength Steel | Vehicle Body Panels |

| Electronics | Nanomaterials | Electronic Components |

| Construction | High-Performance Concrete | Building Foundations |

Material Selection Process

Material selection is a key aspect of material engineering, requiring a deep understanding of the characteristics and performance of various materials. The process involves evaluating the properties of different materials to determine their suitability for a particular application, considering factors such as durability, cost, and environmental impact.

Criteria for Choosing Materials

When selecting materials, engineers consider several critical criteria. These include mechanical properties such as strength, toughness, and hardness, as well as thermal properties like conductivity and resistance to heat. Additionally, factors such as corrosion resistance, recyclability, and cost-effectiveness play a significant role in the decision-making process.

The selection process often involves a trade-off between different properties. For instance, a material might offer high strength but be expensive or difficult to process. Engineers must weigh these factors to choose a material that best meets the project’s requirements.

Case Studies in Material Selection

Several case studies illustrate the importance of careful material selection. For example, in the aerospace industry, the selection of lightweight yet strong materials like titanium alloys has enabled the development of more fuel-efficient aircraft. In contrast, the construction industry has seen the adoption of advanced concrete materials that offer improved durability and resistance to environmental degradation.

One notable case study involves the use of advanced composites in the automotive industry. By selecting materials with the right balance of strength, weight, and cost, manufacturers have been able to produce vehicles that are not only more fuel-efficient but also safer and more environmentally friendly.

These examples demonstrate the critical role that material selection plays in the success of engineering projects across various industries. By understanding the properties and potential applications of different materials, engineers can make informed decisions that enhance the performance, sustainability, and cost-effectiveness of their projects.

Advanced Material Technologies

The advent of advanced material technologies is revolutionizing industries worldwide. These technologies enable the creation of complex materials and structures that were previously impossible to produce, opening new avenues for innovation and application.

3D Printing and Additive Manufacturing

3D printing, also known as additive manufacturing, is a process of creating objects by layering materials such as metals, polymers, and ceramics. This technology allows for the production of complex geometries and customized products with reduced material waste.

Composites technology plays a crucial role in 3D printing, enabling the creation of strong, lightweight components for aerospace and automotive industries. For instance, a study by NASA highlighted the use of 3D printing to produce rocket engine components, significantly reducing production time and costs.

| Industry | Application | Benefit |

|---|---|---|

| Aerospace | Rocket engine components | Reduced production time and costs |

| Automotive | Customized car parts | Increased design flexibility |

Smart Materials and Their Uses

Smart materials are designed to respond to environmental stimuli, such as temperature or light. These materials have a wide range of applications, from nanomaterials used in electronics to self-healing materials in construction.

“The development of smart materials is a significant step forward in material science, enabling the creation of adaptive systems that can improve performance and efficiency.” –

The use of smart materials is becoming increasingly prevalent in various industries. For example, in the medical field, shape-memory alloys are used in stents that can expand when heated to body temperature.

Biomaterials in Medicine

Biomaterials are engineered to interact with biological systems, making them crucial for medical applications. These materials are used in implants, prosthetics, and drug delivery systems, improving patient outcomes and quality of life.

The development of biocompatible materials has been a significant area of research, with applications in tissue engineering and regenerative medicine. For instance, researchers have developed scaffolds that support tissue growth, potentially revolutionizing the treatment of organ failures.

Sustainability in Material Engineering

As the world grapples with environmental challenges, material engineering is playing a crucial role in promoting sustainability. The need for eco-friendly materials and sustainable practices has never been more pressing, and material engineers are at the forefront of this change.

The importance of sustainability in material engineering cannot be overstated. With the increasing demand for materials in various industries, the environmental impact of material production and disposal has become a significant concern. Material engineers are developing innovative solutions to minimize waste, reduce energy consumption, and promote the use of renewable materials.

Eco-Friendly Material Choices

One of the key strategies in sustainable material engineering is the selection of eco-friendly materials. These materials are designed to have a lower environmental impact throughout their lifecycle, from production to disposal. Examples include bioplastics, which are made from renewable biomass sources, and recycled metals, which reduce the need for primary metal production.

The use of eco-friendly materials is not limited to specific industries; it is a widespread practice that can be seen in various sectors, including construction, automotive, and consumer goods. For instance, the construction industry is increasingly using sustainable timber and low-carbon concrete to reduce its environmental footprint.

Recycling and Reuse of Materials

Another critical aspect of sustainability in material engineering is the recycling and reuse of materials. By closing the material loop, engineers can significantly reduce waste and the demand for new raw materials. Advanced recycling technologies are being developed to improve the efficiency and quality of recycled materials.

The benefits of recycling and reusing materials are multifaceted. Not only does it conserve natural resources, but it also reduces energy consumption and greenhouse gas emissions associated with material production. For example, recycling aluminum uses 95% less energy than producing primary aluminum.

- Improved resource efficiency

- Reduced environmental impact

- Cost savings through reduced waste disposal and raw material costs

In conclusion, sustainability is a vital component of modern material engineering. By focusing on eco-friendly material choices and the recycling and reuse of materials, material engineers can significantly contribute to a more sustainable future.

Challenges in Material Engineering

Material engineers are tasked with overcoming complex challenges to develop materials that meet the increasingly demanding requirements of modern industries. The field of material engineering is inherently interdisciplinary, involving aspects of physics, chemistry, and engineering to design and develop materials with specific properties.

As technology advances, the need for materials with enhanced performance characteristics becomes more pressing. This demand drives material engineers to innovate and push the boundaries of what is currently possible.

Common Obstacles in Development

One of the primary challenges in material engineering is the development of materials that can withstand extreme conditions, such as high temperatures or corrosive environments. Material failure is a significant concern, as it can lead to catastrophic consequences in applications like aerospace or medical devices.

- Developing materials with improved strength-to-weight ratios

- Enhancing resistance to corrosion and wear

- Creating materials that can operate effectively at high temperatures

To address these challenges, material engineers employ advanced characterization techniques and modeling tools to understand material behavior under various conditions.

Addressing Material Failures

Failure analysis is a critical aspect of material engineering, involving the investigation of material failures to identify root causes and implement corrective actions. Post-failure analysis helps in understanding the mechanisms leading to failure, which is crucial for improving material design and processing techniques.

| Failure Mode | Causes | Mitigation Strategies |

|---|---|---|

| Corrosion | Environmental exposure, material defects | Coatings, material selection |

| Fatigue | Cyclic loading, material weaknesses | Design optimization, material processing |

| Fracture | Overload, material defects | Material testing, design safety factors |

By understanding and addressing material failures, engineers can develop more reliable and durable materials, enhancing the safety and performance of engineering systems.

The challenges in material engineering are multifaceted, requiring a comprehensive approach that involves understanding material properties, behavior under various conditions, and failure mechanisms. By addressing these challenges, material engineers play a crucial role in advancing technology and improving the quality of life.

Future Trends in Material Engineering

As we look ahead, material engineering is on the cusp of a new era driven by innovation and technological advancements. The field is rapidly evolving, with significant breakthroughs expected in the coming years.

Emerging Technologies to Watch

Several emerging technologies are poised to revolutionize material engineering. Nanomaterials, for instance, are being increasingly used to create materials with unique properties. These materials have a wide range of applications, from electronics to medicine.

- Advances in composites technology are leading to stronger, lighter materials.

- The development of smart materials that can respond to environmental stimuli is another exciting area.

- Nanotechnology is enabling the creation of materials with tailored properties at the atomic level.

These emerging technologies are not only improving existing materials but also enabling the creation of entirely new classes of materials with unprecedented properties.

Predictions for Next Decade

Looking ahead to the next decade, several trends are expected to shape the future of material engineering. Sustainability will continue to be a major driver, with a focus on developing eco-friendly materials and processes.

“The future of material engineering lies in creating materials that are not only high-performance but also sustainable and environmentally friendly.” – Expert in Material Science

The next decade will also see significant advancements in:

- The use of 3D printing and additive manufacturing to create complex material structures.

- The development of biomaterials for medical applications, improving healthcare outcomes.

- The integration of artificial intelligence in material design and discovery processes.

These predictions highlight the exciting future ahead for material engineering, with potential breakthroughs that could transform various industries and improve our quality of life.

Education and Career Paths in Material Engineering

Education plays a crucial role in shaping the careers of material engineers, who are in high demand across various industries. A strong educational foundation is essential for success in this field.

Degree Programs and Certifications

Material engineers typically pursue degrees in materials science, materials engineering, or related fields. Undergraduate and graduate programs provide a comprehensive understanding of materials properties, processing, and applications.

- Bachelor’s degrees in Materials Science or Engineering

- Master’s and Ph.D. programs for advanced research and specialization

- Certifications from professional organizations, such as the ASM International

These educational pathways equip material engineers with the knowledge and skills needed to innovate and solve complex problems.

Internships and Job Opportunities

Gaining practical experience through internships and research projects is vital for material engineers. Industry internships provide hands-on experience, while research opportunities foster innovation and expertise.

- Internships with leading companies in aerospace, automotive, and electronics

- Research positions in academia and national laboratories

- Job opportunities in manufacturing, R&D, and consulting

By combining academic knowledge with real-world experience, material engineers can pursue rewarding careers that drive technological advancements.

Notable Material Engineering Organizations

The advancement of material engineering is largely attributed to the efforts of prominent professional organizations. These entities foster innovation, facilitate collaboration, and disseminate knowledge among material engineers worldwide.

ASM International

ASM International is a renowned organization dedicated to advancing materials science and engineering. With a rich history, ASM provides a platform for professionals to share knowledge, network, and stay updated on the latest developments in the field.

Some key activities of ASM International include:

- Organizing conferences and workshops

- Publishing scientific journals and books

- Offering certifications and professional development programs

The Materials Research Society

The Materials Research Society (MRS) is another pivotal organization in the field of materials research. MRS brings together scientists, engineers, and educators to share research advancements and explore new areas in materials science.

| Organization | Focus Area | Key Activities |

|---|---|---|

| ASM International | Materials Science and Engineering | Conferences, Publications, Certifications |

| The Materials Research Society | Materials Research and Development | Meetings, Publications, Awards |

Both ASM International and The Materials Research Society play vital roles in promoting professional development and collaboration among material engineers. Their contributions significantly impact the advancement of material engineering, shaping the future of various industries.

Case Studies in Material Engineering Successes

Advances in material engineering have led to remarkable successes in multiple sectors. These achievements are a testament to the field’s potential to drive innovation and improve our daily lives.

Material engineering has played a crucial role in the development of new technologies and products. One of the key areas where material engineering has made a significant impact is in the aerospace industry.

Innovations in Aerospace Materials

The aerospace industry has benefited greatly from advancements in material engineering, particularly in the development of lightweight, high-strength composites. These materials have enabled the creation of more fuel-efficient aircraft, reducing operational costs and environmental impact.

For instance, the use of carbon fiber reinforced polymers (CFRP) in aircraft structures has become increasingly common. CFRP offers a high strength-to-weight ratio, making it an ideal material for aerospace applications.

“The use of advanced composites in aerospace has revolutionized the industry, enabling the production of lighter, more efficient aircraft.” –

A comparison of traditional materials with advanced composites highlights the benefits of material engineering in aerospace:

| Material | Weight | Strength |

|---|---|---|

| Aluminum | 2.7 g/cm³ | 400 MPa |

| CFRP | 1.8 g/cm³ | 600 MPa |

Breakthroughs in Medical Devices

Material engineering has also led to significant advancements in medical devices, particularly in the development of biomaterials. These materials are designed to be compatible with the human body, reducing the risk of adverse reactions.

For example, the development of biocompatible titanium alloys for orthopedic implants has improved the durability and safety of these devices. Additionally, advancements in polymer science have led to the creation of biodegradable stents, which can dissolve in the body over time.

The impact of these breakthroughs is evident in the improved outcomes for patients undergoing medical procedures involving these devices.

The Global Impact of Material Engineering

The field of material engineering has a profound impact on global economic growth and quality of life. As a discipline, it encompasses the development and application of various materials to drive technological advancements and improve infrastructure.

Contributions to Economic Growth

Material engineering significantly contributes to economic growth by enabling the development of new products, improving manufacturing processes, and enhancing infrastructure. Innovations in materials science lead to the creation of more efficient, durable, and cost-effective materials that drive industries forward.

For instance, advancements in materials research have led to breakthroughs in renewable energy technologies, such as more efficient solar panels and wind turbines. These advancements not only contribute to economic growth but also help in reducing our reliance on fossil fuels, thereby supporting sustainable development.

Enhancing Quality of Life

Material engineering also plays a crucial role in enhancing the quality of life. The development of new materials and technologies has led to significant improvements in healthcare, transportation, and consumer products. For example, biomaterials developed through materials engineering have revolutionized medical devices and implants, improving patient outcomes and saving lives.

Furthermore, the application of advanced materials in construction and infrastructure projects has resulted in safer, more durable buildings and roads. This not only enhances the quality of life for individuals but also contributes to the overall well-being of communities.

In conclusion, material engineering has a far-reaching impact on both economic growth and the quality of life. As the field continues to evolve, we can expect even more innovative solutions that will shape the future of various industries and improve our daily lives.

Conclusion: The Future of Material Engineering

Material engineering is a vital field that has the potential to shape the future. As we have explored throughout this article, its impact is felt across various industries, from aerospace to medicine.

Key Takeaways

The field of material engineering encompasses a broad range of materials, including metals, polymers, ceramics, and composites. Understanding the properties and applications of these materials is crucial for driving innovation and improving our daily lives.

Exploring Your Path

For those interested in pursuing a career in material engineering, there are numerous opportunities available. By developing a strong foundation in materials science and staying up-to-date with the latest advancements, individuals can contribute to the exciting developments in this field and drive career development.

As material engineering continues to evolve, it is essential to explore new materials and technologies that can drive innovation and improve our daily lives. We encourage readers to explore their path in material engineering and contribute to the exciting developments in this field, leveraging the latest advancements in material engineering and materials science.