Can effective treatment of industrial wastewater really make a difference in environmental sustainability?

The answer lies in understanding the critical role that wastewater engineering plays in protecting public health and the environment. As industrial activities continue to grow, the need for advanced wastewater treatment technologies becomes increasingly important.

Advanced processing technologies are used to remove contaminants from water before they enter public water sources, ensuring a safer and healthier environment.

Key Takeaways

- Understanding the importance of industrial wastewater treatment

- The role of advanced technologies in wastewater engineering

- Environmental sustainability and public health benefits

- Overview of the comprehensive guide’s content

- Significance of effective wastewater management

Understanding Industrial Wastewater

Industrial wastewater, a byproduct of various industrial processes, poses substantial environmental and health risks if not managed properly. Organizations have a responsibility to limit their impact on local communities and the surrounding environment.

Definition and Importance of Industrial Wastewater

Industrial wastewater is water that has been contaminated or otherwise affected by heavy industrial processes. Proper management of industrial wastewater is crucial for wastewater treatment solutions and overall industrial water management. Effective treatment and management practices are essential to mitigate its harmful effects on the environment.

Types of Industrial Wastewater

Industrial wastewater can be categorized based on its source and characteristics. Common types include:

- Wastewater from manufacturing processes

- Wastewater generated by the chemical industry

- Wastewater from the food and beverage sector

- Wastewater discharged by the textile industry

Environmental Impacts

The environmental impacts of industrial wastewater are significant and can include water pollution, soil contamination, and harm to aquatic life. If not properly treated, industrial wastewater can lead to long-term ecological damage.

Regulatory Framework

The management of industrial wastewater is governed by a complex regulatory framework that includes federal, state, and industry-specific guidelines. Compliance with these regulations is crucial for industries to avoid legal repercussions and minimize their environmental footprint.

Sources of Industrial Wastewater

The sources of industrial wastewater are multifaceted and widespread across different sectors. Industrial activities generate a significant volume of wastewater, which can contain a variety of pollutants depending on the nature of the industry.

Manufacturing Processes

Manufacturing processes are a significant source of industrial wastewater. Industries such as automotive, aerospace, and electronics produce wastewater through various processes, including machining, cleaning, and surface treatment. Effective wastewater system design is crucial in these industries to manage the diverse range of contaminants.

Chemical Industry Contributions

The chemical industry is another major contributor to industrial wastewater. The production of chemicals involves numerous processes that generate wastewater containing complex and often hazardous substances. Implementing sustainable wastewater practices in the chemical industry is vital to mitigate environmental impacts.

Food and Beverage Sector

The food and beverage sector also generates substantial amounts of wastewater, primarily from processing and cleaning operations. This wastewater can contain high levels of organic matter and nutrients. Adopting sustainable wastewater practices in this sector can help reduce environmental footprint and comply with regulatory standards.

Textile Industry Discharges

The textile industry is known for its significant water usage and subsequent wastewater generation, often containing dyes, chemicals, and other pollutants. Efficient wastewater system design and treatment are essential for this industry to minimize its environmental impact.

Understanding the sources and characteristics of industrial wastewater is the first step towards effective management and treatment. By adopting sustainable wastewater practices and improving wastewater system design, industries can reduce their environmental footprint while complying with regulatory requirements.

Water Quality Standards

Water quality standards play a pivotal role in safeguarding public health and environmental integrity by regulating industrial effluent discharge. These standards are crucial for ensuring that industrial wastewater does not harm the environment or public health.

Federal Water Quality Regulations

The United States Environmental Protection Agency (EPA) sets federal water quality regulations under the Clean Water Act. These regulations establish standards for various pollutants and provide guidelines for industries to follow.

Key aspects of federal regulations include:

- Effluent guidelines for different industries

- Water quality criteria for various pollutants

- Permit requirements for discharge into water bodies

State-Specific Standards

While federal regulations provide a baseline, individual states may have more stringent standards based on local environmental conditions. Industries must comply with both federal and state regulations.

Examples of state-specific considerations include:

- Stricter limits on certain pollutants

- Additional monitoring requirements

- Special protections for sensitive ecosystems

Industry-Specific Guidelines

Different industries have unique wastewater characteristics, necessitating industry-specific guidelines. For instance, the textile industry has different effluent concerns compared to the chemical manufacturing sector.

Industry-specific guidelines often address:

| Industry | Specific Concerns | Guideline Focus |

|---|---|---|

| Textile | Dye and chemical runoff | Color removal, chemical treatment |

| Chemical Manufacturing | Toxic chemical discharge | Neutralization, containment procedures |

By understanding and adhering to these water quality standards, industries can minimize their environmental impact while complying with legal requirements.

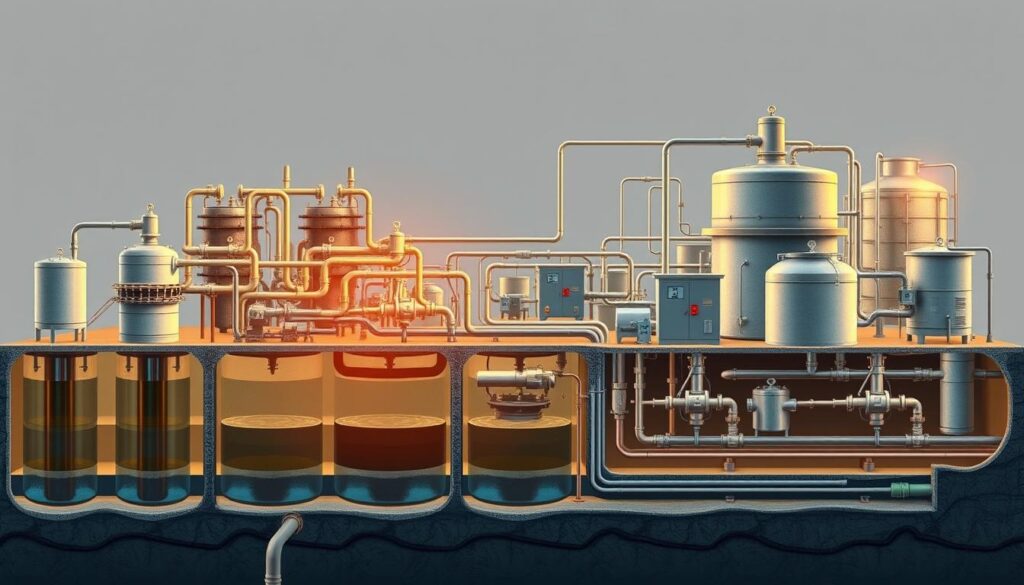

Treatment Methods for Industrial Wastewater

The treatment of industrial wastewater is a complex process requiring various technologies. Industrial wastewater treatment involves multiple steps, including physical, chemical, and biological treatment processes. The choice of treatment method depends on the type and quantity of contaminants present in the wastewater.

Primary Treatment Processes

Primary treatment processes are designed to remove large objects and suspended solids from the wastewater. These processes typically involve physical methods such as screening, grit removal, and sedimentation.

Key primary treatment methods include:

- Screening to remove large objects

- Grit removal to eliminate abrasive materials

- Sedimentation to remove suspended solids

Secondary Treatment Solutions

Secondary treatment solutions focus on removing organic matter and other pollutants through biological processes. These can include activated sludge systems, trickling filters, and lagoons.

| Method | Description | Efficiency |

|---|---|---|

| Activated Sludge | Biological process using microorganisms | High |

| Trickling Filters | Fixed film biological process | Medium to High |

| Lagoons | Large ponds for natural treatment | Low to Medium |

Tertiary and Advanced Treatment Methods

Tertiary and advanced treatment methods are used to further purify the wastewater, often involving chemical or physical processes. These can include filtration, disinfection, and advanced oxidation processes.

Advanced treatment technologies offer several benefits, including:

- Improved water quality

- Increased efficiency in removing contaminants

- Potential for water reuse

By combining these treatment methods, industries can effectively manage their wastewater, minimizing environmental impacts and complying with regulatory standards.

Biological Treatment Technologies

The use of microorganisms to break down organic matter is a cornerstone of modern wastewater treatment. Biological treatment technologies utilize these microorganisms to effectively reduce the organic load in industrial wastewater, making it a crucial component of industrial water recycling and wastewater engineering.

Aerobic Treatment Systems

Aerobic treatment systems use oxygen to support the growth of microorganisms that break down organic matter. These systems are highly effective for treating wastewater with high organic content and are commonly used in various industrial applications.

Key Features of Aerobic Treatment Systems:

- High efficiency in removing organic pollutants

- Ability to handle high organic loading rates

- Production of less odorous sludge compared to anaerobic systems

Anaerobic Treatment Systems

Anaerobic treatment systems operate without the use of oxygen, relying on anaerobic microorganisms to degrade organic matter. These systems are particularly useful for treating high-strength wastewater and producing biogas as a valuable byproduct.

Advantages of Anaerobic Treatment Systems:

- Energy recovery through biogas production

- Lower sludge production compared to aerobic systems

- Ability to treat high-strength wastewater

Advantages of Biological Treatment

Biological treatment technologies offer several advantages, including cost-effectiveness, environmental sustainability, and the ability to remove a wide range of pollutants. The choice between aerobic and anaerobic systems depends on the specific characteristics of the wastewater and the treatment objectives.

| Treatment Aspect | Aerobic Systems | Anaerobic Systems |

|---|---|---|

| Oxygen Requirement | Yes | No |

| Biogas Production | No | Yes |

| Sludge Production | Higher | Lower |

| Energy Consumption | Higher | Lower |

By understanding the principles and applications of biological treatment technologies, industries can make informed decisions about their wastewater treatment strategies, contributing to more effective industrial water recycling and wastewater engineering practices.

Chemical Treatment Approaches

Chemical treatment approaches are pivotal in addressing the complex challenges of industrial wastewater treatment solutions. These methods involve the addition of chemicals to induce reactions that facilitate the removal of contaminants.

Coagulation and Flocculation

Coagulation and flocculation are critical processes in chemical treatment. Coagulation involves the addition of chemicals to neutralize the charges on suspended particles, allowing them to stick together. Flocculation follows, where the particles form larger clumps, or flocs, that are easier to remove. For instance, chemical treatment of wastewater often utilizes coagulants like alum or ferric chloride.

| Chemical | Application | Effectiveness |

|---|---|---|

| Alum | Coagulation | High |

| Ferric Chloride | Coagulation | High |

| Polymers | Flocculation | Variable |

Oxidation Processes

Oxidation processes are another vital aspect of chemical treatment. These involve the use of oxidizing agents to break down organic contaminants. Common oxidizing agents include chlorine, ozone, and hydrogen peroxide. Oxidation can effectively degrade complex organic molecules, making them easier to remove from wastewater.

“Oxidation processes are essential for the degradation of persistent organic pollutants in industrial wastewater, enhancing the overall efficiency of treatment systems.” –

Neutralization Techniques

Neutralization techniques are used to adjust the pH of wastewater, ensuring it is neither too acidic nor too alkaline before discharge or further treatment. This is typically achieved through the addition of acids or bases. Neutralization is crucial for protecting aquatic life and preventing damage to treatment infrastructure.

Implementing these chemical treatment approaches can significantly enhance the effectiveness of sustainable wastewater practices. By understanding the applications and limitations of coagulation, flocculation, oxidation, and neutralization, industries can better manage their wastewater, contributing to a cleaner environment.

Physical Treatment Techniques

In the realm of wastewater system design, physical treatment techniques are fundamental to achieving water quality standards. These methods are crucial for removing suspended solids and other contaminants from industrial effluents, thereby protecting the environment and public health.

Sedimentation

Sedimentation is a widely used physical treatment technique that involves the removal of suspended solids from wastewater by allowing them to settle to the bottom of a tank. This process is based on the principle that particles denser than water will settle under the influence of gravity.

- Types of Sedimentation Tanks: There are various designs, including circular and rectangular tanks, each with its own advantages.

- Advantages: Sedimentation is effective for removing a wide range of particle sizes and is relatively simple to operate.

Filtration

Filtration is another critical physical treatment method used to remove suspended solids and other contaminants from industrial wastewater. It involves passing the wastewater through a filter medium, such as sand or activated carbon, to capture the impurities.

“Filtration is a key step in many industrial wastewater treatment processes, offering a high degree of contaminant removal.” –

- Filter Types: Common filter types include gravity filters, pressure filters, and multimedia filters.

- Applications: Filtration is used in various industries, including manufacturing and food processing.

Membrane Technologies

Membrane technologies represent a cutting-edge approach to physical treatment, utilizing semi-permeable membranes to separate contaminants from wastewater. These technologies can achieve high removal efficiencies for a wide range of pollutants.

- Types of Membranes: Microfiltration, ultrafiltration, nanofiltration, and reverse osmosis are commonly used in industrial wastewater treatment.

- Benefits: Membrane technologies offer compact design, high efficiency, and the potential for water reuse.

By incorporating these physical treatment techniques into industrial water management strategies, facilities can significantly improve the quality of their effluent, contributing to a more sustainable and environmentally friendly operation.

Wastewater Reuse and Recycling

Wastewater reuse and recycling have emerged as crucial strategies in industrial effluent management. As industries seek to minimize their environmental footprint, the importance of reusing and recycling wastewater has gained significant attention.

Benefits of Wastewater Reuse

The benefits of wastewater reuse are multifaceted. Water conservation is a primary advantage, as reusing wastewater reduces the demand on freshwater resources. Additionally, wastewater reuse can lead to a reduction in the amount of effluent discharged into the environment, thereby minimizing environmental impacts.

- Reduced water consumption

- Lower effluent discharge

- Cost savings on water procurement

For more information on the role of wastewater reuse in sustainability, visit Stanley Consultants.

Case Studies of Successful Reuse

Several industries have successfully implemented wastewater reuse systems. For instance, a textile manufacturing plant in the United States adopted a wastewater recycling program that enabled the reuse of up to 80% of its wastewater. This not only reduced the plant’s water consumption but also decreased its effluent discharge.

- A food processing company implemented a wastewater reuse system, achieving a 50% reduction in water consumption.

- A chemical manufacturing facility adopted advanced treatment technologies to recycle its wastewater, resulting in a significant decrease in environmental impacts.

Guidelines for Safe Reuse

To ensure safe wastewater reuse, industries must adhere to strict guidelines. This includes implementing appropriate wastewater treatment technologies to meet the required water quality standards for the intended reuse application.

- Conduct thorough water quality assessments

- Implement appropriate treatment technologies

- Monitor and maintain treatment systems regularly

By following these guidelines and learning from successful case studies, industries can effectively implement wastewater reuse and recycling programs, contributing to a more sustainable future.

Emerging Technologies in Wastewater Treatment

The future of wastewater treatment is being shaped by cutting-edge technologies that promise to enhance efficiency, reduce costs, and promote sustainability. As the industry continues to evolve, it’s crucial to stay abreast of the latest innovations that are transforming the way we manage wastewater.

Innovative Filtration Systems

One of the significant advancements in wastewater treatment is the development of innovative filtration systems. These systems utilize advanced materials and technologies to remove contaminants more effectively. For instance, membrane bioreactors (MBRs) combine biological treatment with membrane filtration, offering a compact and efficient solution for treating industrial wastewater.

- Advanced membrane technologies

- High-efficiency filtration systems

- Integrated treatment solutions

These innovative filtration systems are not only improving the quality of treated water but also reducing the footprint of treatment plants. As highlighted in a recent study on innovations in industrial wastewater treatment, such technologies are pivotal in achieving sustainable water management.

Advanced Oxidation Processes

Advanced oxidation processes (AOPs) represent another critical area of innovation in wastewater treatment. AOPs involve the use of oxidizing agents to break down complex pollutants into simpler, less harmful substances. Techniques such as ozonation, Fenton’s process, and photocatalytic oxidation are being employed to treat a wide range of industrial effluents.

- Ozonation for disinfection and oxidation

- Fenton’s process for degradation of organic pollutants

- Photocatalytic oxidation for removal of persistent contaminants

These advanced oxidation processes are particularly effective in removing recalcitrant pollutants that are resistant to conventional treatment methods. By integrating AOPs into their treatment trains, industries can achieve higher levels of water quality and comply with stringent environmental regulations.

Smart Water Management Solutions

The integration of smart technologies into water management systems is revolutionizing the way wastewater is treated and managed. Smart water management solutions involve the use of sensors, IoT devices, and data analytics to optimize treatment processes, predict maintenance needs, and improve overall system efficiency.

By leveraging these smart solutions, industries can not only enhance the performance of their wastewater treatment plants but also reduce operational costs and environmental impacts. For example, real-time monitoring and control systems enable operators to respond quickly to changes in wastewater characteristics, ensuring consistent treatment quality.

In conclusion, emerging technologies in wastewater treatment, including innovative filtration systems, advanced oxidation processes, and smart water management solutions, are set to transform the industry. By adopting these cutting-edge technologies, industries can improve treatment efficiency, reduce costs, and contribute to a more sustainable future.

Economic Considerations

Effective industrial wastewater management not only mitigates environmental impacts but also offers substantial economic benefits. As industries continue to grow, understanding the economic aspects of wastewater treatment becomes crucial for sustainable operations.

Cost Analysis of Treatment Systems

The cost of wastewater treatment systems varies widely depending on the technology and scale implemented. A detailed cost analysis is essential to determine the most economically viable solution for industrial operations.

Key cost factors include:

- Initial investment in equipment and infrastructure

- Operating and maintenance costs

- Energy consumption

- Chemical and material expenses

| Treatment Technology | Initial Cost | Operating Cost |

|---|---|---|

| Physical Treatment | $100,000 | $5,000/month |

| Biological Treatment | $200,000 | $3,000/month |

| Chemical Treatment | $150,000 | $4,000/month |

Long-term Financial Benefits

While there are significant upfront costs associated with wastewater treatment systems, there are also considerable long-term financial benefits. These include savings on water consumption through recycling and reduced regulatory compliance costs.

“Investing in advanced wastewater treatment technologies can lead to significant cost savings and improved operational efficiency.” –

Industries that adopt efficient wastewater management practices can benefit from:

- Reduced water consumption through recycling

- Lower regulatory compliance costs

- Potential revenue from selling treated water

Funding and Grants for Industrial Projects

Various funding options and grants are available to support industrial wastewater treatment projects. These can significantly offset the initial investment costs.

Industries can explore government grants, low-interest loans, and private investment opportunities to fund their wastewater treatment initiatives. It’s essential to research and identify the most suitable funding sources for specific projects.

Case Studies in Industrial Wastewater Management

Industrial wastewater management plays a pivotal role in maintaining ecological balance and ensuring compliance with environmental regulations. Effective management strategies are often developed and refined through the analysis of real-world case studies.

Successful Corporate Implementations

Several corporations have successfully implemented innovative wastewater treatment solutions, significantly reducing their environmental footprint. For instance, a leading chemical manufacturing company implemented a state-of-the-art industrial effluent treatment system, achieving a 90% reduction in wastewater discharge.

- Implemented advanced biological treatment technologies to enhance effluent quality.

- Utilized membrane filtration to remove contaminants and recover valuable resources.

- Adopted a zero-liquid discharge (ZLD) policy to minimize environmental impact.

Lessons Learned from Industrial Failures

Analyzing industrial failures in wastewater management provides valuable insights into common pitfalls and areas for improvement. A notable example is a textile industry facility that faced significant regulatory and environmental challenges due to inadequate wastewater treatment.

- Insufficient pretreatment led to the failure of downstream treatment processes.

- Lack of regular maintenance resulted in equipment failures and costly downtime.

- Inadequate training of personnel hindered effective operation of treatment systems.

Comparative Analyses of Treatment Facilities

Comparative studies of different wastewater treatment facilities help identify best practices and areas for improvement. A comprehensive analysis of various industrial effluent treatment plants revealed significant differences in treatment efficiencies and operational costs.

| Treatment Technology | Efficiency | Operational Cost |

|---|---|---|

| Biological Treatment | 85% | $0.05/m³ |

| Advanced Oxidation | 95% | $0.10/m³ |

| Membrane Filtration | 90% | $0.08/m³ |

These case studies underscore the importance of tailored wastewater treatment solutions and continuous improvement in industrial wastewater management practices.

Challenges in Industrial Wastewater Engineering

Effective industrial wastewater engineering requires addressing the multifaceted challenges that arise from regulatory compliance, technological constraints, and public perception. The complexity of these challenges necessitates a comprehensive approach that balances technical, economic, and social considerations.

Compliance with Regulations

One of the primary challenges in industrial wastewater engineering is ensuring compliance with regulations. Industrial facilities must adhere to stringent federal, state, and local regulations governing wastewater discharge. For instance, the Environmental Protection Agency (EPA) sets national standards that industries must follow. Compliance involves regular monitoring, reporting, and maintaining detailed records of wastewater treatment processes.

Industries must also stay updated on changing regulations and adapt their practices accordingly. This can be resource-intensive, requiring significant investment in training and infrastructure. Moreover, non-compliance can result in severe penalties, including fines and reputational damage.

| Regulatory Aspect | Description | Impact on Industry |

|---|---|---|

| Federal Regulations | Set by EPA, these regulations provide a national framework for wastewater management. | Industries must comply with national standards, which can influence operational practices. |

| State-Specific Standards | States may have additional or more stringent regulations than federal standards. | Industries operating in multiple states must navigate varying regulatory landscapes. |

| Local Regulations | Local authorities may impose further restrictions based on regional environmental concerns. | Industries must be aware of and comply with local regulations, which can be more stringent. |

Technological Limitations

Technological limitations pose another significant challenge in industrial wastewater engineering. While various treatment technologies are available, each has its limitations in terms of efficiency, cost, and applicability. For example, advanced oxidation processes can be effective for treating certain contaminants but may be prohibitively expensive for widespread adoption.

The development and implementation of new technologies are crucial for overcoming these limitations. Innovations such as membrane bioreactors and advanced filtration systems are enhancing the efficiency and effectiveness of wastewater treatment. However, the adoption of these technologies requires significant investment and often involves a learning curve.

Public Perception and Stakeholder Engagement

Public perception and stakeholder engagement are increasingly important in industrial wastewater engineering. Communities are becoming more aware of environmental issues, and industries are under growing pressure to demonstrate their commitment to sustainable practices. Effective stakeholder engagement involves transparent communication about wastewater management practices and their environmental impact.

Industries can benefit from adopting sustainable wastewater practices that not only comply with regulations but also address public concerns. This can involve implementing wastewater reuse and recycling programs, investing in green infrastructure, and engaging in community outreach initiatives.

By addressing these challenges comprehensively, industries can improve their wastewater management practices, enhance their reputation, and contribute to sustainable wastewater system design. This requires a concerted effort to balance regulatory compliance, technological innovation, and stakeholder engagement.

Future Trends in Wastewater Engineering

Wastewater engineering is on the cusp of a new era, driven by innovations in AI, automation, and sustainable practices. As the world grapples with the challenges of water scarcity and pollution, the need for effective and sustainable wastewater management solutions has never been more pressing.

Sustainable Practices

Sustainable practices are becoming increasingly important in wastewater engineering. This includes the adoption of energy-efficient treatment processes, water reuse and recycling, and the minimization of waste generation. Industrial water management is critical in this context, as it involves not only treating wastewater but also reducing water consumption and promoting water conservation.

One of the key sustainable practices is the implementation of circular economy principles. This involves designing systems where water is reused and recycled, reducing the demand on freshwater resources and minimizing the environmental impact of wastewater discharge.

Integration of AI and Automation

The integration of AI and automation is revolutionizing wastewater treatment processes. Advanced sensors and monitoring systems enable real-time data collection, allowing for more precise control over treatment processes. AI algorithms can analyze this data to predict potential issues, optimize treatment efficiency, and reduce operational costs.

Environmental engineering services are leveraging these technologies to provide innovative solutions for wastewater management. Automation is also improving the reliability and consistency of treatment processes, reducing the risk of human error and enabling more efficient maintenance.

Global Perspectives on Wastewater Solutions

Wastewater management is a global challenge that requires collaborative and innovative solutions. Different regions face unique challenges, from water scarcity in arid areas to pollution from industrial activities in densely populated areas.

Global perspectives on wastewater solutions involve sharing knowledge, technologies, and best practices across borders. This includes international collaborations on research and development, capacity building in developing countries, and the adoption of global standards for wastewater treatment and reuse.

By embracing these future trends, the wastewater engineering sector can make significant strides in improving industrial water management and promoting sustainable water practices worldwide.

Professional Resources and Organizations

Industry associations, certification programs, and educational institutions play a crucial role in the ongoing development of wastewater engineering professionals. These resources support the advancement of wastewater treatment technology and promote best practices in industrial water recycling.

Key Industry Associations

Several key industry associations are dedicated to supporting professionals in the field of wastewater engineering. These organizations provide valuable resources, including research publications, conferences, and networking opportunities.

- The Water Environment Federation (WEF) is a prominent organization that offers training programs, publications, and conferences focused on wastewater treatment and water quality.

- The American Water Works Association (AWWA) provides resources on water treatment and supply, including publications and conferences relevant to industrial water recycling.

Certification Programs for Professionals

Certification programs are essential for ensuring that wastewater engineers have the necessary knowledge and skills. These programs often focus on specific areas such as wastewater treatment technology and industrial water recycling.

Examples of certification programs include:

- The Certified Wastewater Treatment Operator program, which is designed to certify operators of wastewater treatment plants.

- The Water Quality Certification program, offered by some institutions to certify professionals in water quality management.

Educational Institutions Offering Relevant Programs

Various educational institutions offer programs relevant to wastewater engineering, ranging from undergraduate degrees to professional certifications. These programs cover topics such as wastewater treatment technology, industrial water recycling, and environmental regulations.

Some notable institutions include:

- Universities with environmental or civil engineering departments that offer courses or degrees in water resources management.

- Technical colleges that provide training programs for wastewater treatment operators.

Conclusion and Key Takeaways

Effective industrial wastewater engineering is crucial for protecting the environment and public health. A comprehensive approach that incorporates best practices, innovative technologies, and a commitment to sustainability is essential for successful wastewater treatment plant design.

Best Practices in Industrial Wastewater Engineering

Implementing best practices in industrial wastewater engineering involves understanding the sources and types of industrial wastewater, adhering to water quality standards, and utilizing appropriate treatment methods. By combining primary, secondary, and tertiary treatment processes, industries can significantly reduce their environmental footprint.

Driving Innovation in Wastewater Treatment

Continued innovation in industrial wastewater engineering is vital for addressing emerging challenges and improving treatment efficiency. Advances in technologies such as membrane filtration, advanced oxidation processes, and smart water management solutions are enhancing the effectiveness of wastewater treatment plant design.

Future of Industrial Wastewater Engineering

As industries continue to evolve, the importance of industrial wastewater engineering will only grow. By adopting sustainable practices, investing in research and development, and collaborating with regulatory bodies, industries can ensure a healthier environment and comply with increasingly stringent regulations.