As countries worldwide expand their high-speed rail networks to address transportation challenges, the demand for specialized knowledge in track construction continues to grow. This article explores the critical components, engineering challenges, and technological innovations that make high-speed rail tracks possible, with insights valuable for civil engineers and infrastructure planners working in this specialized field.

The Global Importance of High-Speed Rail Systems

High-speed rail has transformed transportation landscapes across Europe and Asia, with China leading global development with over 38,000 km of operational high-speed rail lines. Japan’s Shinkansen, Europe’s extensive cross-border networks, and emerging systems in the United States demonstrate the worldwide recognition of HSR’s value.

The significance of high-speed rail track construction extends beyond mere transportation efficiency. These systems deliver substantial environmental benefits by reducing carbon emissions compared to air and road travel. According to the International Union of Railways (UIC), high-speed rail is more than four times as energy-efficient as car travel and nearly nine times more efficient than flying.

Want to learn more about global high-speed rail standards?

Download our comprehensive guide to international high-speed rail construction standards and specifications.

For infrastructure planners and engineers, high-speed rail track construction presents unique challenges that demand specialized knowledge and innovative approaches. The safety and efficiency requirements are significantly more stringent than conventional rail, with track geometry tolerances measured in millimeters rather than centimeters.

Safety Demands

- Precise track alignment with minimal deviations

- Structural integrity at extreme speeds

- Resistance to thermal expansion and contraction

- Minimal settlement over decades of operation

- Resilience against environmental factors

Efficiency Requirements

- Optimized energy consumption through smooth transitions

- Minimized maintenance requirements

- Extended service life of components

- Reduced noise and vibration generation

- Integration with existing infrastructure

Key Components of High-Speed Rail Track Construction

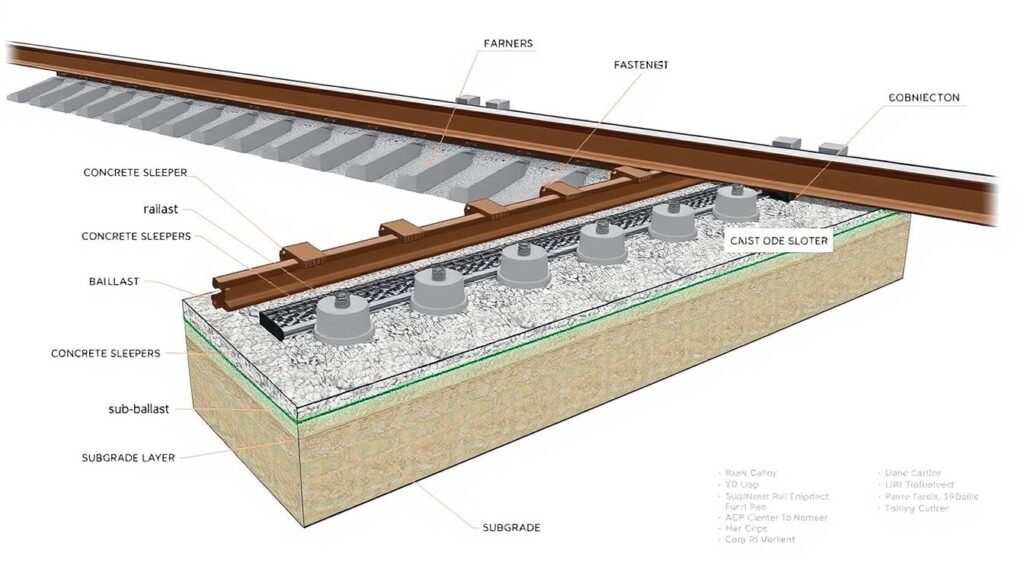

The exceptional performance of high-speed rail systems depends on specialized track components engineered to withstand extreme forces while maintaining precise geometry. These components work together as an integrated system, with each element designed to exacting specifications.

Track Materials: Engineering for Speed and Durability

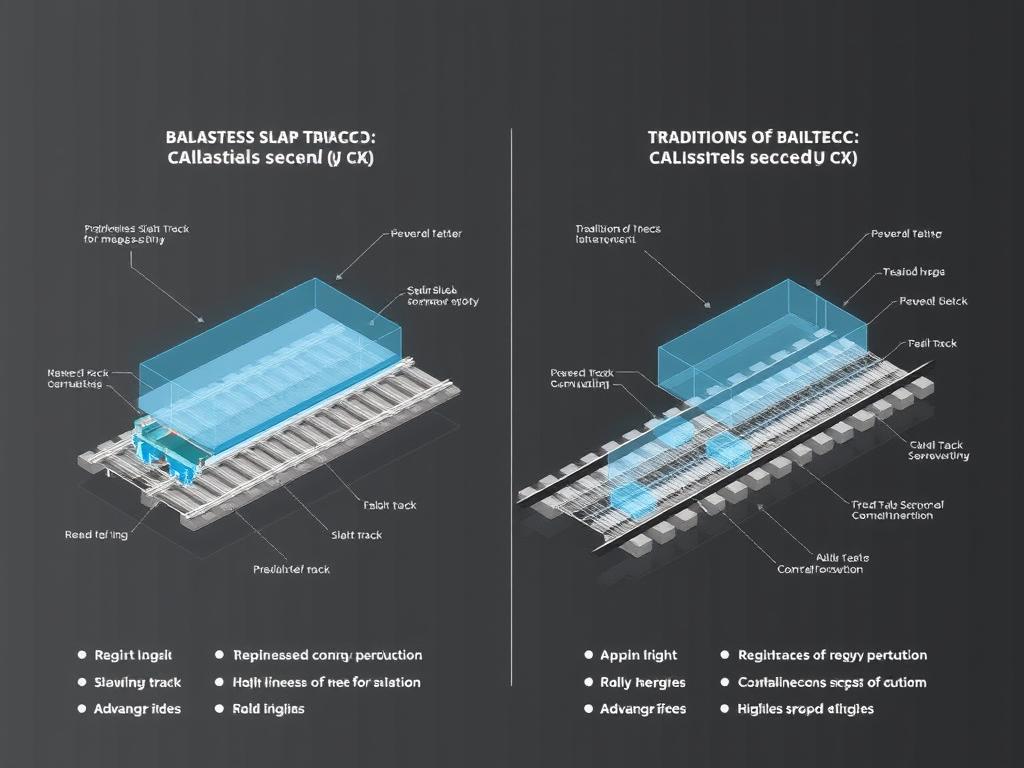

High-speed rail tracks utilize continuous welded rails (CWR) that eliminate the traditional joints found in conventional tracks. These seamless rails, often manufactured to the EN 13674 standard, minimize vibration and provide a smoother ride at high speeds.

| Component | Specification | Function | Advantage for HSR |

| Continuous Welded Rails | 60E1/UIC60 profile, R350HT grade steel | Primary running surface | Eliminates joints, reduces vibration and maintenance |

| Concrete Sleepers | Prestressed monoblock, 2.6m length | Rail support and load distribution | Greater stability and resistance to lateral movement |

| Fastening Systems | Elastic clip systems with rubber pads | Secure rails to sleepers | Absorbs vibration, maintains gauge |

| Ballast | Hard stone, 31.5-50mm, 30cm depth | Load distribution, drainage | Maintains track geometry, dampens vibration |

| Ballastless Slab Track | Reinforced concrete with embedded rail supports | Alternative to ballasted track | Minimal maintenance, precise geometry |

Concrete sleepers (or ties) for high-speed rail are typically prestressed monoblock designs that provide greater stability and resistance to lateral movement than traditional wooden sleepers. These are spaced more closely together—often at 60cm intervals rather than the 70-75cm spacing used in conventional tracks—to provide additional support for the higher loads and speeds.

Precision Alignment Techniques

The geometric precision required for high-speed rail tracks far exceeds that of conventional railways. Vertical alignment tolerances are typically limited to ±2mm over a 20m chord length, while horizontal alignment must be maintained within ±3mm. These exacting standards necessitate specialized surveying and construction methods.

Modern high-speed rail construction employs computer-guided alignment systems that use GPS and robotic total stations to achieve millimeter-level precision. These systems continuously monitor track position during installation and make real-time adjustments to ensure compliance with design specifications.

Master Precision Track Alignment

Access our technical whitepaper on advanced surveying and alignment techniques for high-speed rail construction projects.

Vibration-Dampening Substructures

Controlling vibration is critical in high-speed rail track construction. Excessive vibration not only creates passenger discomfort but also accelerates component degradation and increases maintenance requirements. Advanced substructure designs incorporate multiple layers of materials with specific vibration-dampening properties.

The foundation of high-speed rail tracks typically consists of:

- Subgrade: Compacted to 95-98% of maximum dry density

- Frost protection layer: Prevents frost heave in cold climates

- Sub-ballast: Granular material that distributes loads and provides drainage

- Geotextiles: Prevent migration of fine particles between layers

- Ballast or concrete slab: Primary support structure

In urban areas or on bridges, additional vibration mitigation measures may include under-sleeper pads, ballast mats, or floating slab systems that use rubber or steel spring isolators to minimize the transmission of vibration to surrounding structures.

Engineering Challenges in High-Speed Rail Track Construction

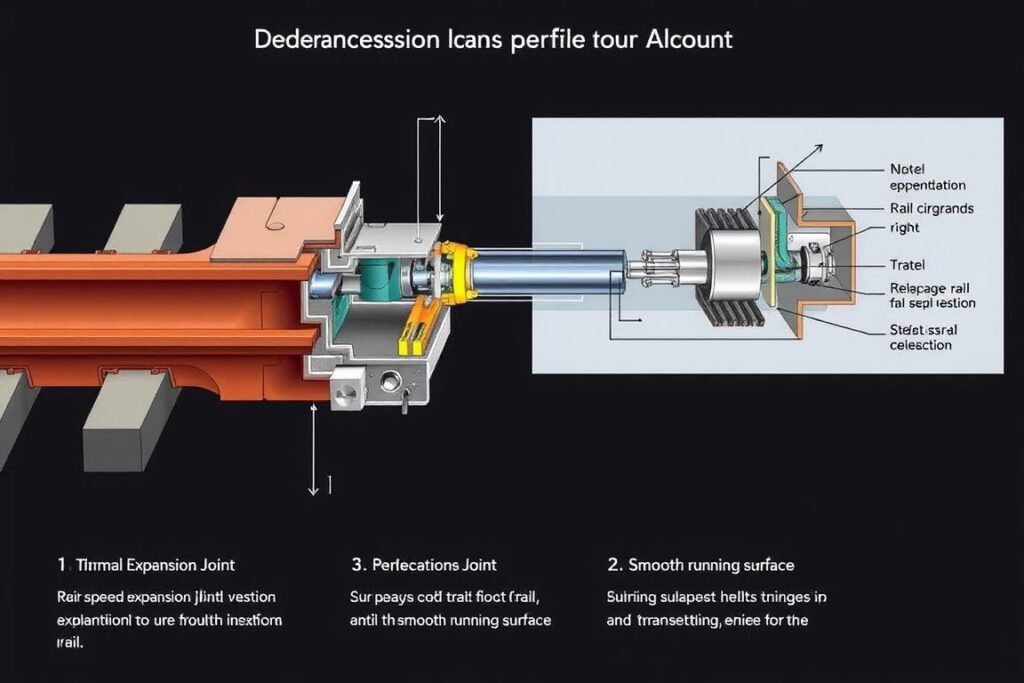

Thermal Expansion Management

High-speed rail tracks experience significant thermal forces due to temperature variations. Steel rails can expand or contract by up to 2.5cm per 100m with a 45°C temperature change. Without proper management, these forces can cause track buckling (sun kinks) in hot weather or rail breaks in cold conditions.

Engineers address thermal expansion through several strategies:

Stress-Free Temperature

Rails are installed at a “neutral” temperature (typically 25°C) to balance expansion and contraction potential throughout the year.

Expansion Joints

Strategic placement of specialized expansion devices at bridges and other fixed structures accommodates movement without compromising track integrity.

Continuous Monitoring

Advanced sensor systems track rail temperature and stress levels, alerting maintenance teams to potential issues before failures occur.

Maintenance of Geometric Precision

Maintaining the precise geometry of high-speed rail tracks presents significant challenges over the operational life of the system. Even minor deviations can lead to increased dynamic forces, passenger discomfort, and accelerated component wear.

Modern high-speed rail systems employ continuous monitoring systems that use inertial measurement units, laser scanners, and computer vision to detect geometric irregularities before they become problematic. These systems enable predictive maintenance approaches that address issues before they affect operations.

“The difference between conventional and high-speed rail track maintenance is not just quantitative but qualitative. We’re not just maintaining to tighter tolerances—we’re fundamentally changing how we approach track geometry management.”

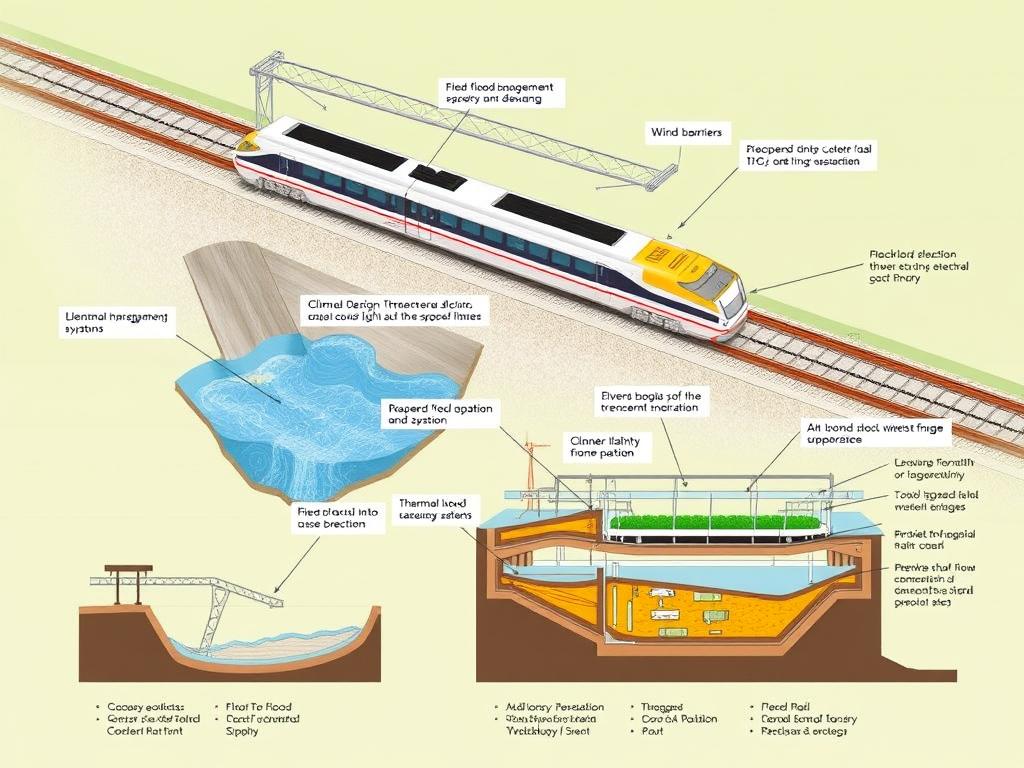

Weather Resistance Strategies

High-speed rail tracks must withstand diverse environmental conditions while maintaining operational safety. Weather-related challenges include:

Weather Challenges

- Heavy rainfall causing ballast washout

- Snow and ice accumulation

- Extreme heat causing rail expansion

- High winds affecting stability

- Flooding of track sections

Engineering Solutions

- Enhanced drainage systems with increased capacity

- Heating elements embedded in critical switches

- Specialized rail stress management systems

- Windbreaks and aerodynamic design features

- Elevated track sections in flood-prone areas

In regions with extreme weather conditions, additional protective measures may include snow sheds in mountainous areas, specialized drainage systems in high-rainfall regions, or heat-resistant materials in desert environments.

Overcome Environmental Challenges

Get our comprehensive guide to weather-resistant high-speed rail track construction techniques for challenging environments.

Technological Innovations in Track Construction

The evolution of high-speed rail track construction has been accelerated by technological innovations that improve efficiency, quality, and sustainability. These advancements are transforming how tracks are designed, built, and maintained.

Automated Track-Laying Machines

Modern high-speed rail construction utilizes sophisticated track-laying machines that can install up to 1.5 kilometers of track per day—significantly faster than conventional methods. These machines perform multiple operations simultaneously, including:

- Precise positioning of sleepers at exact intervals

- Placement and alignment of rails

- Installation of fastening systems

- Distribution and compaction of ballast

- Initial track tamping and alignment

These automated systems not only increase construction speed but also improve quality by eliminating human variability and ensuring consistent adherence to design specifications.

AI-Powered Quality Control Systems

Artificial intelligence and machine learning technologies are revolutionizing quality control in high-speed rail track construction. These systems use multiple data sources to verify compliance with specifications and identify potential issues:

| Technology | Application | Benefit |

| Computer Vision | Automated inspection of rail welds and components | Detects microscopic defects invisible to human inspectors |

| LiDAR Scanning | High-precision measurement of track geometry | Creates digital twin of track for ongoing comparison |

| Ground Penetrating Radar | Substructure inspection and void detection | Identifies hidden issues before they affect track performance |

| Predictive Analytics | Analysis of construction data to predict potential failures | Enables preventive interventions before problems develop |

These AI systems continuously learn from each project, improving their accuracy and effectiveness over time. The result is a significant reduction in construction defects and long-term maintenance requirements.

Sustainable Construction Materials

Environmental sustainability has become a key consideration in high-speed rail track construction. Innovative materials are reducing the carbon footprint and environmental impact of these massive infrastructure projects:

- Carbon-sequestering concrete that absorbs CO₂ during curing

- Recycled plastic composite sleepers with longer service life than concrete

- Ballast made from recycled construction waste

- Bio-based polymers for vibration dampening components

- Solar-powered track monitoring systems

These sustainable materials not only reduce environmental impact but often offer performance advantages such as improved durability, reduced weight, or enhanced vibration dampening properties.

Implement Sustainable Track Solutions

Discover how sustainable materials can improve performance while reducing environmental impact in your high-speed rail project.

Case Studies in High-Speed Rail Track Construction

Japan’s Shinkansen Track Network

Japan’s Shinkansen system, operational since 1964, represents one of the most successful implementations of high-speed rail track technology. The system has achieved an extraordinary safety record with zero passenger fatalities due to derailments or collisions in over 50 years of operation.

Key engineering features of the Shinkansen track system include:

- Dedicated tracks separated from conventional rail and road crossings

- Slab track construction on approximately 80% of the network

- Advanced earthquake early warning systems and derailment prevention

- Continuous welded rails with specialized expansion joints

- Minimal curvature with large radius turns (minimum 4,000m radius)

The Shinkansen’s track maintenance regime is equally impressive, with specialized maintenance vehicles that conduct comprehensive inspections at speeds up to 270 km/h. These “Doctor Yellow” trains use multiple sensing technologies to detect even minor deviations in track geometry, enabling preventive maintenance before issues affect service.

California High-Speed Rail Project Challenges

The California High-Speed Rail project represents America’s most ambitious high-speed rail initiative, designed to connect Los Angeles and San Francisco with trains operating at speeds up to 350 km/h (220 mph). The project has faced numerous engineering challenges, providing valuable lessons for future high-speed rail developments.

Key Construction Challenges:

- Seismic design requirements in an active earthquake zone

- Complex tunneling through the Pacheco Pass in the Coast Ranges

- Integration with existing urban infrastructure

- Varied terrain from flat Central Valley to mountainous regions

- Environmental mitigation requirements

The project has pioneered innovative solutions, including advanced seismic isolation systems for viaducts and bridges, and specialized track designs that can accommodate the significant temperature variations between the Central Valley and coastal regions. These engineering solutions will inform future high-speed rail projects in seismically active regions worldwide.

China’s CR450 Track Advancements

China has developed the world’s most extensive high-speed rail network in just over a decade, with more than 38,000 kilometers in operation. The country’s latest innovation is the CR450 track standard, designed to support operational speeds of 450 km/h (280 mph).

The CR450 track system incorporates several advanced features:

Structural Innovations

- Enhanced slab track with improved vibration dampening

- Specialized rail profiles with optimized aerodynamics

- Increased curve radii (minimum 7,000m for full speed)

- Advanced fastening systems with greater lateral stability

Monitoring Technologies

- Fiber optic sensors embedded throughout the track structure

- Real-time stress and temperature monitoring

- Automated inspection using machine vision systems

- Digital twin technology for predictive maintenance

China’s experience with the CR450 system demonstrates that speeds well beyond current international norms are technically feasible with appropriate track construction techniques. The knowledge gained from this system is likely to influence high-speed rail development globally in the coming decades.

Explore Global Case Studies in Detail

Access our comprehensive collection of high-speed rail track construction case studies from projects around the world.

Future Trends in High-Speed Rail Track Construction

The evolution of high-speed rail track technology continues to accelerate, with several emerging trends poised to shape the next generation of systems. These innovations promise to increase speeds, reduce costs, and enhance sustainability.

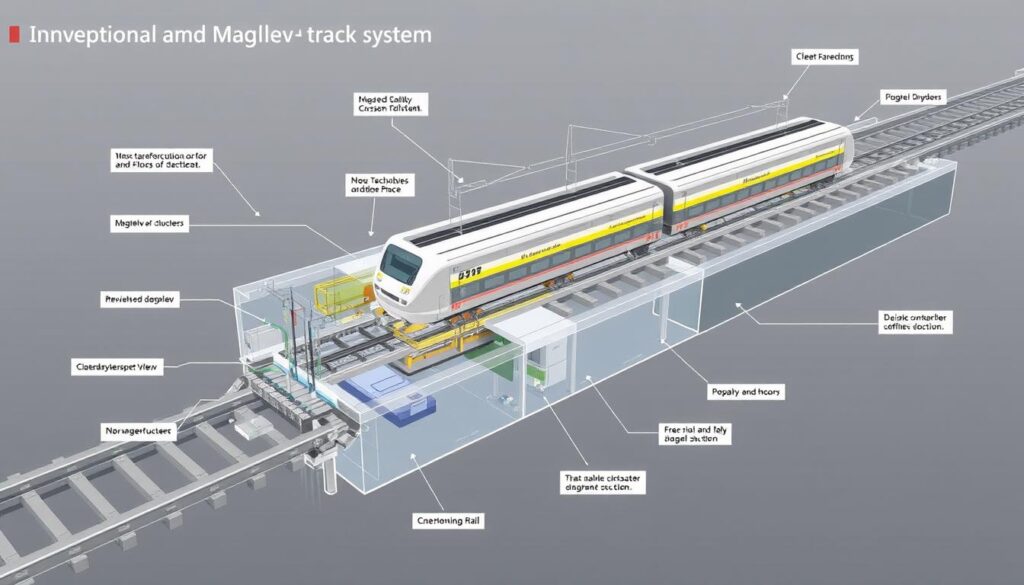

Maglev Track Integration Possibilities

Magnetic levitation (maglev) technology eliminates the traditional wheel-rail interface, allowing for significantly higher speeds—up to 600 km/h (373 mph) in commercial service. While current maglev systems require completely separate infrastructure from conventional rail, research is exploring hybrid approaches that could allow for more flexible implementation.

Potential integration strategies include:

- Convertible track sections that can accommodate both conventional and maglev trains

- Shared corridors with parallel conventional and maglev tracks

- Transition zones allowing trains to switch between conventional and maglev operation

- Standardized station interfaces serving both technologies

These integration approaches could enable phased implementation of maglev technology within existing high-speed rail networks, potentially offering a migration path to higher speeds without requiring complete system replacement.

Smart Tracks with Embedded Sensors

The integration of Internet of Things (IoT) technology into high-speed rail tracks is creating “smart infrastructure” capable of self-monitoring and adaptive response. These systems incorporate thousands of sensors throughout the track structure to provide real-time data on conditions and performance.

| Sensor Type | Measurement | Application |

| Fiber Optic Strain Gauges | Microscopic deformation | Detect structural stress and fatigue |

| Accelerometers | Vibration patterns | Identify developing geometric irregularities |

| Temperature Sensors | Rail and ambient temperature | Manage thermal expansion and contraction |

| Moisture Detectors | Water content in substructure | Prevent ballast degradation and subgrade failure |

| Load Cells | Dynamic wheel loads | Identify vehicle defects and track issues |

Advanced analytics platforms process this sensor data to create predictive models that can forecast maintenance needs weeks or months in advance. Some systems are even developing self-healing capabilities, with automated mechanisms that can make minor adjustments to track geometry without human intervention.

Climate-Adaptive Construction Methods

As climate change increases the frequency and severity of extreme weather events, high-speed rail track construction is evolving to incorporate greater resilience and adaptability. These climate-adaptive approaches include:

Elevated Designs

Raising track structures above potential flood levels and incorporating enhanced drainage systems to manage increased precipitation.

Thermal Management

Developing rail materials and expansion systems capable of withstanding wider temperature extremes and more rapid fluctuations.

Wind Protection

Implementing aerodynamic barriers and structural reinforcements to maintain operations during stronger and more frequent high-wind events.

These climate-adaptive designs often incorporate modular components that can be quickly replaced or upgraded as conditions change or new technologies emerge. This approach creates infrastructure that can evolve over its operational lifetime rather than requiring complete reconstruction to address changing environmental conditions.

Stay Ahead with Future Track Technologies

Download our research report on emerging technologies in high-speed rail track construction and their potential applications.

Conclusion: The Future of High-Speed Rail Track Construction

High-speed rail track construction represents one of the most demanding and innovative areas of civil engineering. The exacting requirements for precision, durability, and performance drive continuous advancement in materials, techniques, and technologies. As global high-speed rail networks continue to expand, these innovations will play a crucial role in making these systems faster, more efficient, and more sustainable.

For civil engineers and infrastructure planners, the field offers exciting opportunities to apply cutting-edge technologies and solve complex challenges. The lessons learned from pioneering projects in Japan, Europe, and China provide valuable insights that can inform new developments worldwide, including emerging high-speed rail initiatives in the United States and other regions.

The future of high-speed rail track construction will likely be characterized by greater integration of digital technologies, increased sustainability, and enhanced adaptability to changing environmental conditions. By embracing these trends, the next generation of high-speed rail systems will continue to push the boundaries of what’s possible in transportation infrastructure.

Master High-Speed Rail Track Engineering

Get our complete technical resource package on high-speed rail track construction, including specifications, case studies, and implementation guides.