The engineering industry is undergoing a significant transformation, thanks to the advent of additive manufacturing. With the ability to create complex prototypes and production-ready parts quickly and cost-effectively, 3D printing is revolutionizing the way engineers design and develop new products.

By leveraging rapid prototyping, engineers can test and refine their designs faster, reducing the time-to-market and improving overall product quality. This technology is not only enhancing the design process but also opening up new possibilities for innovation and creativity.

Key Takeaways

- Rapid prototyping enables faster design testing and refinement.

- Additive manufacturing reduces production time and costs.

- 3D printing enhances design flexibility and innovation.

- Improved product quality through iterative design testing.

- Increased efficiency in the product development process.

Introduction to 3D Printing in Engineering

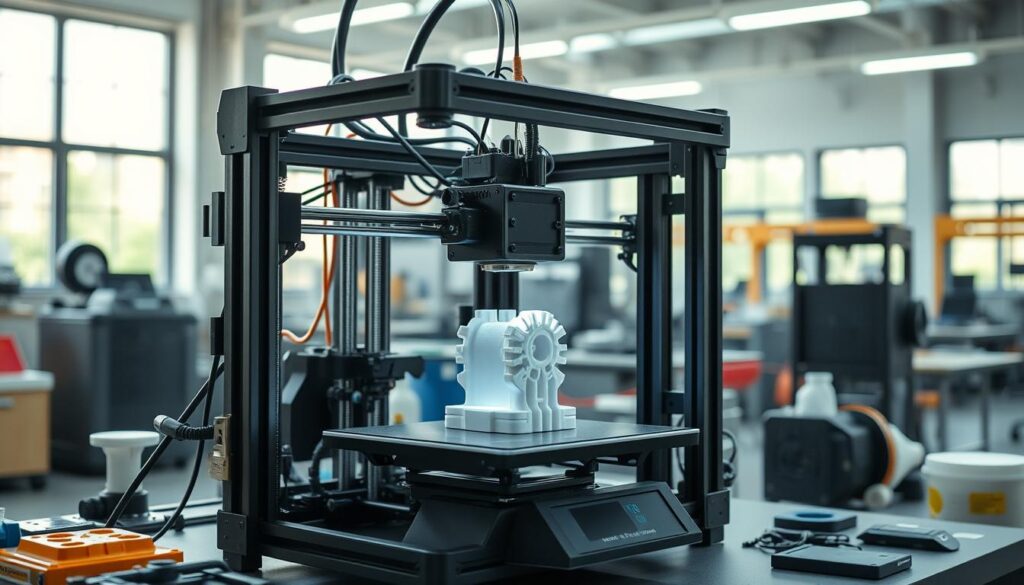

In recent years, 3D printing has emerged as a pivotal force in engineering innovation. This technology, also known as additive manufacturing, is revolutionizing the way products are designed, prototyped, and produced.

3D printing is a process of creating three-dimensional objects from digital files. It involves layering materials such as metals, plastics, and ceramics to form the desired object. As Forbes states, “3D printing is not just about making prototypes; it’s about manufacturing end-products with complex geometries that cannot be produced through traditional methods.”

What is 3D Printing?

At its core, 3D printing technology involves the deposition of material layers to create a three-dimensional object. This process is controlled by sophisticated software that ensures precision and accuracy. Industrial 3D printing has become a critical component in various engineering fields, enabling the production of complex parts with high precision.

A Brief History of 3D Printing

The history of 3D printing dates back to the 1980s when the first additive manufacturing technologies were developed. Since then, the technology has evolved significantly, with advancements in printer resolution, material science, and software. Today, 3D printing services are available globally, offering a range of solutions from prototyping to full-scale production.

As noted by industry experts, “The evolution of 3D printing has been remarkable, transforming from a rapid prototyping tool to a viable manufacturing technology.” This transformation underscores the potential of 3D printing to revolutionize engineering practices.

How 3D Printing Works

3D printing, also known as additive manufacturing, is a process that creates objects layer by layer. This technology has revolutionized the way we design and manufacture products, offering unprecedented flexibility and precision.

The Basic Process Explained

The 3D printing process begins with a digital model of the object to be printed, typically created using computer-aided design (CAD) software. This digital file is then sliced into thin layers, which the 3D printer uses as a guide to deposit 3D printing materials such as plastics, metals, and ceramics.

The printer lays down the material layer by layer, following the design specifications, until the object is complete. This process allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing techniques.

Key Technologies in 3D Printing

Several key technologies are driving the advancements in 3D printing. One of the most significant is the development of new 3D printing materials, which are expanding the range of applications for this technology. For instance, the use of metal and ceramic materials is enabling the production of parts for aerospace and medical industries.

According to a guide on 3D printing, the choice of technology depends on the specific requirements of the project, including the desired material properties and the complexity of the design.

“The future of manufacturing is not just about making things; it’s about making things better, faster, and more efficiently.” –

The collaboration between 3D printing companies and industries is fostering innovation and pushing the boundaries of what is possible with additive manufacturing.

- Fused Deposition Modeling (FDM) is a common technique used for creating prototypes and production parts.

- Stereolithography (SLA) is known for its high resolution and is often used for detailed models and prototypes.

- Selective Laser Sintering (SLS) is a versatile method that can produce durable parts from a variety of materials.

As 3D printing technology continues to evolve, we can expect to see even more innovative applications across various industries.

Advantages of 3D Printing

With its ability to rapidly prototype and produce complex designs, 3D printing is changing the face of engineering. This technology offers several advantages that are transforming the way engineers work, from speeding up production to enabling intricate designs.

Speed of Production

One of the most significant benefits of 3D printing is its ability to accelerate production. Traditional manufacturing methods often involve lengthy processes, including tooling and molding, which can delay product development. In contrast, 3D printing allows for rapid prototyping, enabling engineers to quickly test and iterate their designs.

For instance, companies like Boeing and General Electric have utilized 3D printing to produce parts in a fraction of the time required by conventional methods. This acceleration in production not only speeds up the development process but also allows companies to bring products to market faster.

“3D printing has the potential to revolutionize the way we design and manufacture products, enabling us to create complex geometries and structures that were previously impossible to produce.”

Cost Efficiency

3D printing also offers significant cost advantages. By eliminating the need for tooling and molds, companies can reduce their upfront costs and minimize waste. Additionally, 3D printing enables the production of complex parts in a single step, reducing the need for assembly and minimizing labor costs.

| Cost Factor | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Tooling Costs | High | Low to None |

| Material Waste | Significant | Minimal |

| Labor Costs | High | Lower |

Design Flexibility

Perhaps one of the most exciting advantages of 3D printing is its ability to enable complex designs that would be impossible or impractical with traditional manufacturing methods. Engineers can now design parts with intricate geometries and internal structures that enhance performance and reduce weight.

For example, in the aerospace industry, 3D printing is used to create lightweight components with complex internal structures, improving fuel efficiency and reducing overall weight. This level of design flexibility is opening up new possibilities for innovation in various fields.

In conclusion, the advantages of 3D printing in engineering are multifaceted, offering benefits in speed, cost, and design flexibility. As this technology continues to evolve, it is likely to have an even more significant impact on the engineering landscape.

Applications of 3D Printing in Engineering

Industrial 3D printing is opening new avenues in engineering, enabling the creation of complex components with unprecedented precision. This technology is being increasingly adopted across various engineering disciplines, transforming the way products are designed, prototyped, and manufactured.

Aerospace Engineering

In aerospace engineering, 3D printing technology is being used to manufacture lightweight, high-strength components for aircraft and spacecraft. This not only reduces the overall weight of the vehicles but also enhances their fuel efficiency and performance.

The ability to produce complex geometries allows for the creation of innovative designs that were previously impossible or too costly to produce using traditional manufacturing methods.

Automotive Engineering

The automotive industry is leveraging 3D printing services to accelerate the production of car parts, from prototypes to end-use components. This technology enables the rapid iteration of designs, reducing the time-to-market for new vehicles and components.

Moreover, 3D printing allows for the production of customized parts, enhancing the overall driving experience for consumers.

Medical Devices

In the medical field, 3D printing technology is revolutionizing the production of customized medical devices, implants, and prosthetics. The ability to create patient-specific devices improves the fit, comfort, and functionality of these medical solutions.

Furthermore, the use of biocompatible materials in 3D printing is paving the way for innovative medical applications, including tissue engineering and regenerative medicine.

3D Printing vs. Traditional Manufacturing

3D printing has emerged as a viable alternative to traditional manufacturing, offering several benefits. As industries continue to evolve, understanding the differences between these two methods is crucial for making informed decisions.

When comparing 3D printing and traditional manufacturing, several key factors come into play. These include costs, production timeframes, and material usage. Let’s delve into each of these aspects to understand how they compare.

Comparing Costs

The cost of production is a significant factor in choosing between 3D printing and traditional manufacturing. 3D printing often reduces the need for expensive tooling and molds, making it a cost-effective option for small to medium-sized production runs. According to a study by Xometry, 3D printing can be more economical for complex parts due to its ability to produce them without additional tooling costs.

Here are some key cost-related differences:

- Lower Tooling Costs: 3D printing eliminates the need for expensive molds and tooling.

- Reduced Material Waste: Additive manufacturing processes like 3D printing use material only as needed, reducing waste.

- Efficient Production: For small batches, 3D printing can be more cost-effective due to its ability to produce parts without the need for large-scale production setups.

Comparing Timeframes

Production speed is another critical aspect where 3D printing and traditional manufacturing differ. Traditional manufacturing often involves longer lead times due to the need for tooling and setup. In contrast, 3D printing can significantly reduce production timeframes by allowing for rapid prototyping and production.

Some key timeframe-related differences include:

- Rapid Prototyping: 3D printing enables the quick creation of prototypes, speeding up the development process.

- Faster Production for Complex Parts: 3D printing can produce complex geometries without the need for additional setup, reducing overall production time.

- Just-in-Time Production: With 3D printing, companies can adopt just-in-time production strategies, reducing inventory needs.

Evaluation of Material Use

The choice of material is crucial in both 3D printing and traditional manufacturing. 3D printing materials have evolved significantly, offering a range of options from plastics to metals. The material usage in 3D printing is often more efficient, as it is an additive process that builds parts layer by layer, reducing waste.

In conclusion, while both 3D printing and traditional manufacturing have their strengths and weaknesses, 3D printing offers advantages in terms of cost, speed, and material efficiency for certain applications. As technology continues to advance, the role of 3D printing in manufacturing is likely to expand.

Design Considerations for 3D Printing

When diving into the world of 3D printing, it’s crucial to understand the design considerations that can make or break your project’s success. Designing for 3D printing involves a unique set of considerations that are crucial for engineers and designers to grasp.

One of the primary factors to consider is the material properties. Different materials have varying levels of strength, flexibility, and thermal resistance, which can significantly impact the final product’s performance. For instance, metal 3D printing offers high strength and durability, making it suitable for aerospace and automotive applications.

Optimizing Designs for Additive Manufacturing

Optimizing designs for additive manufacturing involves understanding the capabilities and limitations of 3D printing technology. This includes considering factors such as layer adhesion, support structures, and the potential for complex geometries. By optimizing designs, manufacturers can reduce material waste, improve product performance, and decrease production time.

For example, topology optimization is a design technique that uses algorithms to optimize the internal structure of a part, reducing material usage while maintaining its strength. This technique is particularly useful in industries where weight reduction is critical, such as in aerospace engineering.

| Design Consideration | Impact on 3D Printing | Benefit |

|---|---|---|

| Material Properties | Affects final product performance | Ensures desired product characteristics |

| Layer Adhesion | Influences product strength and durability | Enhances product reliability |

| Support Structures | Impacts printability and post-processing | Simplifies production and reduces costs |

For more insights on design considerations for 3D printing, you can refer to this article on LinkedIn, which provides a detailed analysis of the topic.

Software Tools for 3D Design

The choice of software tools for 3D design is critical in optimizing designs for 3D printing. Various software solutions are available, ranging from CAD software like SolidWorks and Fusion 360 to specialized 3D printing software that can simulate the printing process and identify potential issues.

Using the right software can significantly streamline the design process, improve product quality, and reduce the need for physical prototypes. For instance, rapid prototyping software allows designers to quickly test and iterate on their designs, accelerating the development process.

In conclusion, designing for 3D printing requires a thoughtful approach that considers material properties, layer adhesion, support structures, and the use of appropriate software tools. By understanding these design considerations, engineers and designers can unlock the full potential of 3D printing technology and create innovative products that meet the demands of various industries.

Materials Used in 3D Printing

The versatility of 3D printing is largely attributed to the variety of materials available. 3D printing materials include plastics, metals, ceramics, and composites, each with its own properties and applications. This diversity enables engineers to select the most appropriate material for their specific needs, enhancing the functionality and durability of the final product.

Common Materials in Engineering Applications

In engineering, the choice of material is critical. Plastics are widely used due to their flexibility, durability, and cost-effectiveness. They are ideal for prototypes and models. Metals, on the other hand, offer high strength and thermal resistance, making them suitable for aerospace and automotive applications.

For more detailed information on 3D printing materials, you can visit Formlabs’ blog on 3D printing materials. This resource provides insights into the various materials available and their applications in industrial 3D printing.

| Material | Properties | Applications |

|---|---|---|

| Plastics | Flexible, durable, cost-effective | Prototypes, models, consumer products |

| Metals | High strength, thermal resistance | Aerospace, automotive, industrial machinery |

| Ceramics | High temperature resistance, electrical insulation | Electrical components, aerospace, biomedical devices |

| Composites | High strength-to-weight ratio, customizable properties | Aerospace, automotive, sports equipment |

Future Material Innovations

The future of 3D printing in engineering looks promising, with ongoing research into new materials and technologies. Innovations such as smart materials, nanomaterials, and bio-based materials are expected to further expand the capabilities of 3D printing. These advancements will enable the creation of more complex structures, improve material properties, and open up new possibilities for engineering applications.

Case Studies of 3D Printing Success

3D printing has emerged as a game-changer in engineering, with numerous success stories highlighting its benefits. Companies across various sectors have adopted 3D printing technology to revolutionize their production processes.

Notable Projects

Several notable projects demonstrate the potential of 3D printing applications in engineering. For instance, aerospace companies have utilized rapid prototyping to create complex components with reduced material waste.

- The production of lightweight aircraft parts using 3D printing has resulted in significant fuel efficiency improvements.

- Automotive manufacturers have adopted 3D printing for rapid prototyping, enabling faster design iterations and reduced time-to-market.

- In the medical field, 3D printing has been used to create customized prosthetics and implants, improving patient outcomes.

Key Takeaways

The success stories from various industries highlight key benefits of adopting 3D printing technology. These include:

- Increased efficiency: 3D printing allows for the rapid production of complex parts, reducing lead times.

- Cost savings: By minimizing material waste and reducing the need for assembly, 3D printing can significantly lower production costs.

- Enhanced innovation: The ability to create complex geometries enables the development of innovative products that were previously impossible to manufacture.

As 3D printing applications continue to expand, it is clear that this technology will play a crucial role in shaping the future of engineering.

Sustainability and 3D Printing

3D printing, or additive manufacturing, is not only transforming production lines but also contributing to a more sustainable future. By its very nature, 3D printing is a more environmentally friendly process compared to traditional manufacturing methods.

One of the significant advantages of 3D printing is its ability to reduce waste. Traditional manufacturing often involves subtractive processes, where material is cut away to create the desired product, leading to considerable waste. In contrast, 3D printing adds material layer by layer, precisely as needed, minimizing waste.

Reducing Waste

The reduction of waste in 3D printing is a significant step towards sustainability. By using 3D printing materials more efficiently, manufacturers can lower their environmental footprint. For instance, certain 3D printing technologies allow for the use of recycled materials, further enhancing sustainability.

| Traditional Manufacturing | 3D Printing |

|---|---|

| Subtractive process, high waste | Additive process, minimal waste |

| Often uses non-recyclable materials | Can use recyclable and recycled materials |

Energy Efficiency

Another critical aspect of sustainability in 3D printing is energy efficiency. While 3D printing can be more energy-intensive than traditional methods in some cases, advancements in technology are continually improving its energy efficiency. For example, some 3D printing services are now powered by renewable energy sources, significantly reducing their carbon footprint.

For more information on how 3D printing contributes to sustainability, visit Sustainly’s guide on 3D printing sustainability.

In conclusion, 3D printing offers a promising path towards more sustainable manufacturing practices. By reducing waste and improving energy efficiency, it has the potential to significantly lower the environmental impact of production processes.

Challenges in 3D Printing

Despite its numerous benefits, 3D printing technology is not without its limitations. As the industry continues to grow, it faces several challenges that need to be addressed to fully leverage its potential.

Limitations of Current Technologies

One of the significant challenges in industrial 3D printing is the limitation of current technologies. While 3D printing has advanced significantly, it still struggles with scalability and speed. For instance, producing large-scale parts can be time-consuming and often requires significant post-processing.

A leading 3D printing company recently highlighted the need for advancements in technology to overcome these challenges. Improving the speed and scalability of 3D printing processes is crucial for its wider adoption in industries such as aerospace and automotive.

Material Constraints

Another challenge facing 3D printing technology is material constraints. The range of materials available for 3D printing is still limited compared to traditional manufacturing methods. This limitation affects the mechanical properties and durability of the printed parts.

Researchers are continually working to develop new materials that can enhance the performance of 3D printed products. Until then, the industry will need to work within these material constraints, potentially limiting the applications of industrial 3D printing.

Future Trends in 3D Printing

Emerging trends in 3D printing are expected to significantly impact the engineering sector, driving innovation and efficiency. As technology continues to advance, we can anticipate significant developments in additive manufacturing and rapid prototyping.

The future of 3D printing is closely tied to the development of emerging technologies. One such technology is the integration of artificial intelligence (AI) in 3D printing processes, which is expected to enhance precision and speed. For more insights on the future of 3D printing, visit Xometry’s resource on the future of 3D.

Emerging Technologies

Several emerging technologies are set to revolutionize the 3D printing landscape. These include:

- Advancements in metal 3D printing, enabling stronger and more durable parts.

- The use of biocompatible materials for medical applications.

- Integration of AI for optimized printing processes.

Potential Industry Shifts

The potential industry shifts due to 3D printing are vast. With the ability to produce complex geometries and customized products, industries such as aerospace and automotive are likely to see significant changes. 3D printing in engineering is expected to lead to more efficient production lines and reduced material waste.

As 3D printing technology continues to evolve, it is crucial for industries to adapt and embrace these changes. By doing so, they can leverage the benefits of additive manufacturing to stay competitive in a rapidly changing market.

Conclusion

As we’ve explored throughout this article, 3D printing technology is revolutionizing the engineering industry by offering rapid prototyping, design flexibility, and cost efficiency. The applications of 3D printing are vast, ranging from aerospace and automotive engineering to medical devices.

By leveraging 3D printing services, engineers can create complex designs that were previously impossible to produce. This technology is not only enhancing production but also contributing to sustainable infrastructure and innovation.

Unlocking New Possibilities

The future of 3D printing applications in engineering looks bright, with emerging technologies and potential industry shifts on the horizon. As this technology continues to evolve, it will be crucial for engineers to stay at the forefront of these developments.

Exploring the Potential

For those passionate about solving problems and working with technology, 3D printing presents a wealth of career opportunities. By exploring 3D printing technology further, engineers can unlock new possibilities and drive innovation in their respective fields.