Are you aware that an optimized logistics facility layout can significantly boost your supply chain’s efficiency?

In today’s fast-paced logistics environment, maximizing space and productivity is crucial for businesses to stay competitive. According to recent trends, optimizing cargo facilities is key to achieving this goal.

Effective cargo facility design involves more than just arranging storage and shipping areas; it’s about creating a streamlined process that enhances overall productivity.

Key Takeaways

- Efficient logistics facility layout is crucial for supply chain efficiency.

- Optimizing cargo facilities can significantly boost productivity.

- A well-planned facility design enhances overall business competitiveness.

- Maximizing space is key to reducing operational costs.

- Streamlined processes in cargo facilities improve delivery times.

Understanding Cargo Facility Design

The air cargo industry’s significant growth, fueled by e-commerce and global trade, necessitates a deeper understanding of cargo facility design. Effective design is not just about constructing a building; it’s about creating an efficient, productive, and safe environment that meets the demands of a rapidly evolving industry.

Definition and Importance

Cargo facility design refers to the planning and construction of facilities used for handling, storing, and distributing cargo. The importance of well-designed cargo facilities cannot be overstated, as they directly impact the efficiency of logistics operations, warehouse design solutions play a critical role in this aspect.

A well-designed cargo facility can lead to reduced operational costs, improved safety, and enhanced customer satisfaction. It involves careful planning of the layout, selection of appropriate equipment, and implementation of efficient processes.

Key Components of a Cargo Facility

The key components of a cargo facility include:

- Warehouse space for storing cargo

- Office areas for administrative tasks

- Equipment such as forklifts and conveyor systems for handling cargo

- Security features to protect against theft and damage

For more detailed information on designing cargo facilities, refer to the IATA’s cargo facility design guidelines, which provide comprehensive insights into best practices.

Trends in Cargo Facility Design

Current trends in cargo facility design are influenced by the need for greater efficiency, sustainability, and adaptability. Some of the key trends include:

| Trend | Description |

|---|---|

| Automation | Incorporating automated systems for handling and storing cargo to improve efficiency and reduce labor costs. |

| Sustainability | Designing facilities with energy-efficient systems and sustainable materials to minimize environmental impact. |

| Flexibility | Creating adaptable spaces that can be easily reconfigured to meet changing operational needs. |

As the air cargo industry continues to evolve, understanding these trends and incorporating them into transportation facility planning will be crucial for stakeholders.

Factors Influencing Cargo Facility Design

Effective cargo facility design requires careful consideration of several key factors. The complexity of designing a cargo facility lies in balancing industrial space optimization with the need for advanced technology and adherence to regulatory requirements.

Space Efficiency

Maximizing space efficiency is crucial in distribution center architecture. This involves not only the physical layout but also the strategic use of storage solutions and material handling equipment to minimize waste and enhance productivity.

As noted by industry experts, “Optimizing warehouse space is not just about fitting more inventory into a facility; it’s about creating a seamless flow of goods that enhances overall operational efficiency.”

“The layout of a warehouse or distribution center should be designed to facilitate easy movement of goods, reduce handling times, and improve picking and packing processes.”

Technology Integration

The integration of technology in cargo facilities is transforming the way goods are handled and stored. From warehouse management systems (WMS) to automated storage and retrieval systems (AS/RS), technology plays a vital role in enhancing efficiency and reducing costs.

Implementing the right technology requires a thorough analysis of the facility’s operational needs. As John Smith, a logistics expert, notes, “The right technology can significantly improve the efficiency of cargo handling operations, but it must be carefully selected to meet the specific needs of the facility.”

Local Regulations and Compliance

Cargo facilities must comply with a myriad of local regulations, including those related to safety, security, and environmental impact. Ensuring compliance is not only a legal requirement but also essential for maintaining a facility’s operational integrity.

- Understanding local zoning laws and building codes

- Adhering to safety and security standards

- Implementing environmental sustainability practices

By carefully considering these factors, cargo facility designers can create spaces that are not only efficient and technologically advanced but also compliant with local regulations.

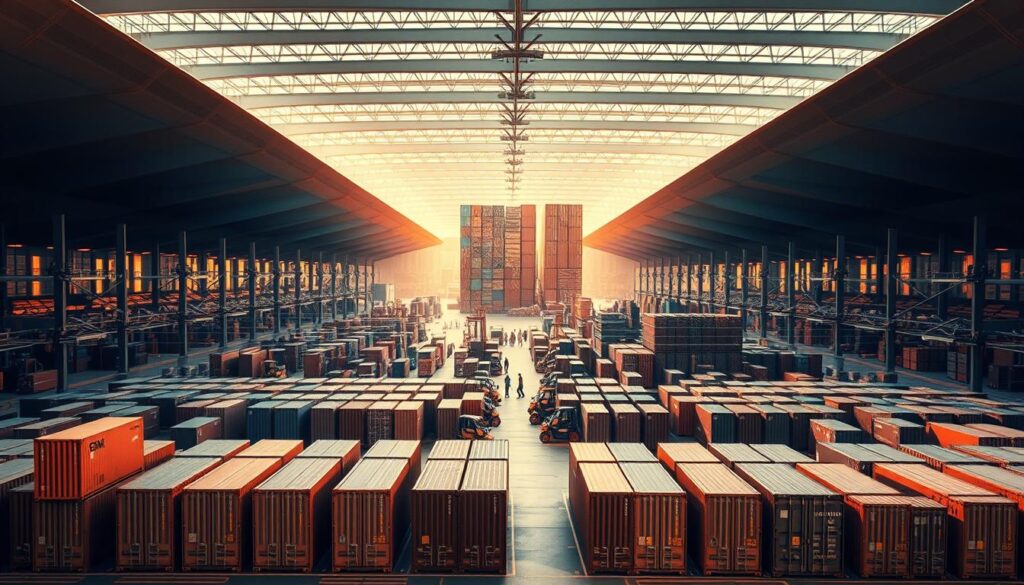

Types of Cargo Facilities

Cargo facilities play a crucial role in the supply chain, with different types catering to specific requirements. The design and functionality of these facilities are tailored to their intended use, ensuring efficient cargo handling building design.

There are several types of cargo facilities, each with unique characteristics. The main types include warehouses, distribution centers, and air cargo terminals.

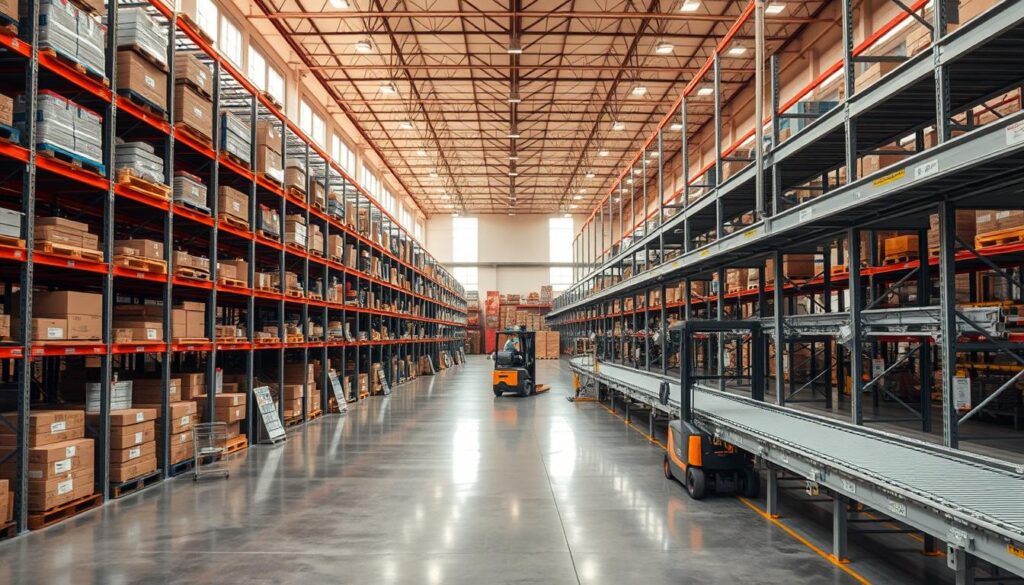

Warehouses

Warehouses are facilities used primarily for the storage of goods. They are a critical component of the supply chain, providing a secure environment for inventory management. Modern warehouses often incorporate advanced technology, such as automated storage and retrieval systems, to enhance efficiency. According to industry experts, “the integration of technology in warehouses is revolutionizing the way goods are stored and managed”

“The future of warehousing lies in its ability to adapt to changing consumer demands and technological advancements.”

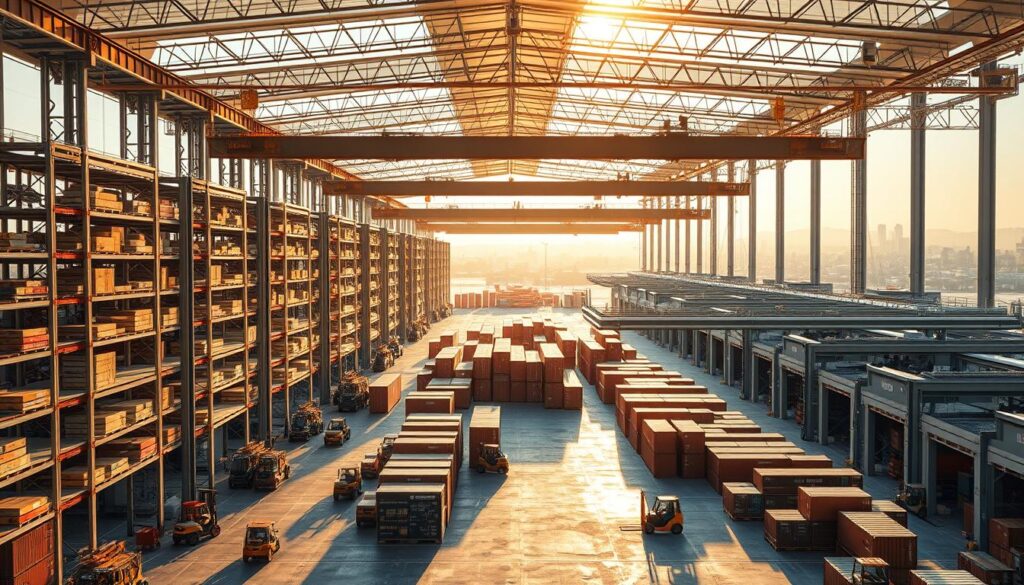

Distribution Centers

Distribution centers are specialized facilities designed for the rapid movement of goods. They are typically located near transportation hubs to facilitate quick and efficient distribution. Distribution centers play a vital role in supply chain facility development, ensuring that products reach their destinations promptly. For more information on distribution centers and their role in the supply chain, you can refer to resources such as transportation network engineering.

Air Cargo Terminals

Air cargo terminals are critical infrastructure for the handling of air freight. These facilities are designed to process cargo quickly and securely, with features such as climate-controlled storage and advanced security systems. Air cargo terminals are essential for international trade, facilitating the rapid movement of goods across borders. For a detailed analysis of air cargo facilities, you can consult documents like the Air Cargo Facility Analysis report.

In conclusion, the various types of cargo facilities are designed to meet specific needs within the supply chain. Understanding these differences is crucial for effective supply chain facility development and cargo handling building design.

Site Selection for Cargo Facilities

Effective site selection for cargo facilities is pivotal in enhancing the overall efficiency of freight terminal construction planning and logistics facility layout. The process involves a comprehensive evaluation of various factors to ensure that the chosen site supports the operational needs of the facility.

Proximity to Transportation

One of the critical factors in site selection is proximity to transportation networks. Being close to highways, ports, or airports can significantly reduce transportation costs and enhance the speed of logistics operations. For instance, a cargo facility near a major port can streamline international trade by reducing transit times.

Land Use Considerations

Land use considerations are another vital aspect of site selection. The availability of sufficient land area is necessary to accommodate not only the current operational needs but also potential future expansions. Additionally, the land should be zoned for industrial use and comply with local land use regulations.

- Assessing the topography of the land to ensure it can support the weight and infrastructure of a cargo facility.

- Evaluating the accessibility of the site for employees and transportation vehicles.

- Considering the availability of utilities such as water, electricity, and telecommunications.

Environmental Impact

The environmental impact of a cargo facility is a significant consideration in the site selection process. Facilities should be designed and located to minimize their ecological footprint. This includes assessing the potential for noise pollution, air quality impacts, and the effect on local ecosystems.

By carefully evaluating these factors, developers and operators can select sites that not only enhance operational efficiency but also comply with environmental regulations and community standards.

Ultimately, the right site selection can lead to cost savings, improved customer satisfaction, and a competitive edge in the logistics market.

Layout and Flow Optimization

The layout and flow of cargo facilities play a pivotal role in determining their overall productivity. An optimized layout not only streamlines operations but also enhances the safety and efficiency of the facility.

Modular Design Concepts

Modular design concepts offer a flexible and scalable approach to cargo facility layout. By incorporating modular elements, facilities can be easily reconfigured to adapt to changing operational needs. This approach is particularly beneficial in warehouse design solutions, where the ability to scale up or down quickly can be a significant advantage.

Some key benefits of modular design include:

- Flexibility in layout configuration

- Ease of expansion or reconfiguration

- Reduced downtime during modifications

For more insights on optimizing warehouse layouts, visit AutoStore System’s guide on warehouse layout.

Workflow Analysis Techniques

Workflow analysis is critical in identifying bottlenecks and inefficiencies within cargo facilities. Techniques such as process mapping and time studies can help in understanding the flow of operations and pinpointing areas for improvement.

In distribution center architecture, workflow analysis can lead to significant gains in productivity. By analyzing the workflow, facilities can identify opportunities to reduce waste, improve throughput, and enhance overall operational efficiency.

Effective workflow analysis involves:

- Mapping out current processes

- Identifying inefficiencies and bottlenecks

- Implementing changes to improve workflow

By adopting these strategies, cargo facilities can achieve a more streamlined and efficient operation, ultimately leading to cost savings and improved customer satisfaction.

Storage Solutions in Cargo Facilities

Optimizing storage solutions is key to enhancing the functionality of cargo facilities. Effective storage is vital for maximizing space and ensuring that operations run smoothly.

One of the primary methods for achieving efficient storage is through the use of racking systems. These systems are designed to maximize vertical space, allowing for more goods to be stored in a smaller footprint. Racking systems come in various configurations, including selective racking, drive-in racking, and push-back racking, each catering to different storage needs and operational requirements.

Racking Systems

Racking systems are a cornerstone of industrial space optimization. By utilizing vertical space, these systems help reduce the need for additional floor space, thus optimizing the use of available area. For instance, selective racking is ideal for operations that require frequent access to a wide range of products.

“The right racking system can significantly improve the efficiency of a cargo facility,” says an industry expert. “It’s about choosing a system that aligns with your operational needs and enhances your storage capacity.”

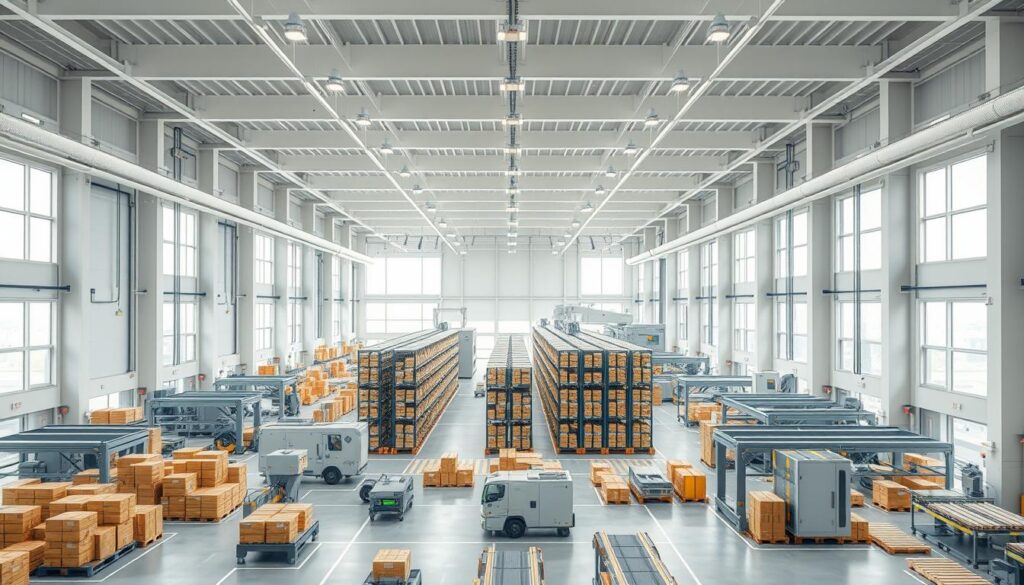

Automated Storage Systems

Another innovative solution is automated storage systems. These systems use technology to store and retrieve items automatically, minimizing the need for manual labor and reducing the risk of errors. Automated storage systems are particularly beneficial for large cargo facilities handling high volumes of goods.

Automated storage systems not only enhance storage capacity but also improve the overall efficiency of cargo handling building design. By integrating automation, facilities can streamline their operations, reduce labor costs, and increase productivity.

In conclusion, the implementation of effective storage solutions such as racking systems and automated storage systems is crucial for the success of cargo facilities. By optimizing storage, facilities can improve their operational efficiency, reduce costs, and enhance their overall competitiveness in the market.

Material Handling Equipment

Cargo facilities rely heavily on material handling equipment to streamline their operations and improve efficiency. The right equipment can significantly reduce labor costs, increase productivity, and enhance the overall safety of the facility.

Forklifts and Pallet Jacks

Forklifts and pallet jacks are among the most commonly used material handling equipment in cargo facilities. Forklifts are versatile and can be used for a variety of tasks, including lifting and moving heavy pallets. Pallet jacks, on the other hand, are ideal for shorter distances and are often used in warehouses and distribution centers.

For more information on warehouse material handling equipment, you can visit https://www.yellowgate.com/blog/warehouse-material-handling-equipment.

Conveyor Systems

Conveyor systems are another crucial component of material handling equipment. They are used to transport goods over long distances within the facility, reducing the need for manual labor and increasing efficiency. There are various types of conveyor systems, including belt conveyors, roller conveyors, and chain conveyors, each with its own unique benefits.

| Equipment Type | Primary Use | Benefits |

|---|---|---|

| Forklifts | Lifting and moving heavy pallets | Versatile, efficient, and reduces labor costs |

| Pallet Jacks | Moving pallets over short distances | Ideal for warehouses and distribution centers, easy to maneuver |

| Conveyor Systems | Transporting goods over long distances | Increases efficiency, reduces manual labor, and enhances safety |

In conclusion, material handling equipment is essential for the efficient operation of cargo facilities. By choosing the right equipment, facilities can improve productivity, reduce costs, and enhance safety.

Sustainable Design Practices

Incorporating sustainable design practices into cargo facilities is no longer a trend, but a necessity for modern supply chain facility development. As the world grapples with environmental challenges, the importance of sustainable practices in cargo facility design has become increasingly evident.

Sustainable design practices not only contribute to reducing the environmental footprint of cargo facilities but also enhance their operational efficiency. By integrating energy-efficient systems and adopting green building certifications, cargo facilities can significantly reduce their energy consumption and operational costs.

Energy Efficiency Strategies

Energy efficiency is a critical component of sustainable design in cargo facilities. Strategies include the use of LED lighting, solar panels, and energy-efficient HVAC systems. These measures not only reduce energy consumption but also lower operational costs, making cargo facilities more competitive.

For instance, a study on energy efficiency in warehouses revealed that the adoption of LED lighting can reduce energy consumption by up to 50%. Similarly, the integration of solar panels can provide a significant portion of a facility’s energy needs, further reducing reliance on non-renewable energy sources.

| Energy Efficiency Measure | Potential Savings | Implementation Cost |

|---|---|---|

| LED Lighting | Up to 50% | Moderate |

| Solar Panels | Up to 70% | High |

| Energy-Efficient HVAC | Up to 30% | High |

Green Building Certifications

Green building certifications, such as LEED (Leadership in Energy and Environmental Design), play a crucial role in promoting sustainable design practices in cargo facility development. These certifications provide a framework for designing and operating buildings in an environmentally friendly manner.

“LEED certification is a recognized standard for sustainable building practices, and its adoption in cargo facility design is a step towards a more sustainable future.”

For more information on sustainable design practices in transport packaging, visit TPM. Additionally, exploring sustainable building materials can provide further insights into green building practices.

Safety Considerations in Design

Effective cargo facility design integrates safety measures to safeguard personnel and prevent potential hazards. Safety is a paramount concern in the design of cargo facilities, as it directly impacts the well-being of employees and the efficiency of operations.

When designing a cargo facility, it is essential to consider various safety aspects to create a secure working environment. This involves not only complying with regulatory requirements but also implementing best practices to minimize risks.

Fire Safety Protocols

Fire safety is a critical component of cargo facility design. Implementing robust fire safety protocols is vital to prevent and mitigate fire hazards. This includes:

- Installing advanced fire detection and suppression systems.

- Ensuring adequate access for firefighting vehicles and personnel.

- Using fire-resistant materials in construction.

- Conducting regular fire safety drills and training for employees.

Fire safety protocols should be integrated into the overall design and operational plans of the cargo facility to ensure a comprehensive safety strategy.

Employee Safety Measures

Protecting employees is a top priority in cargo facility design. Employee safety measures include:

- Designing clear and safe pathways for pedestrian and vehicular traffic.

- Implementing safety signage and warning systems.

- Providing personal protective equipment (PPE) and ensuring its proper use.

- Training employees on safety procedures and emergency response plans.

Effective safety measures not only protect employees but also contribute to a more efficient and productive work environment.

Incorporating safety considerations into the design of cargo facilities is crucial for creating a secure and efficient operational environment. By prioritizing safety, facilities can reduce the risk of accidents, enhance productivity, and ensure compliance with regulatory standards.

Technology in Cargo Facilities

Technology plays a crucial role in modern cargo facilities, streamlining processes and improving productivity. The integration of advanced technologies is transforming the way cargo facilities operate, making them more efficient and competitive.

The use of technology in cargo facilities is not limited to a single aspect; it encompasses a wide range of systems and tools designed to optimize operations. Two key areas where technology has made a significant impact are warehouse management systems and RFID/barcode integration.

Warehouse Management Systems

Warehouse Management Systems (WMS) are software applications that help manage and control the day-to-day operations within a warehouse or distribution center. A robust WMS can significantly enhance warehouse design solutions by optimizing storage capacity, streamlining picking and packing processes, and improving overall operational efficiency.

Some of the key features of a WMS include:

- Inventory management

- Order management

- Labor management

- Reporting and analytics

By implementing a WMS, cargo facilities can achieve better distribution center architecture by ensuring that the layout and operations are optimized for maximum efficiency.

RFID and Barcode Integration

RFID (Radio Frequency Identification) and barcode technology are used to track and manage inventory within cargo facilities. These technologies provide real-time data on inventory levels, location, and status, enabling more accurate and efficient operations.

The benefits of RFID and barcode integration include:

| Technology | Benefits |

|---|---|

| RFID | Real-time tracking, improved accuracy, reduced labor costs |

| Barcode | Cost-effective, easy to implement, accurate inventory tracking |

For more insights on the future of air cargo facilities and the role of technology, refer to the IATA’s 2025 Vision for the Future of Air Cargo.

Cost Management in Cargo Facility Design

To achieve financial success, cargo facility projects must prioritize cost management. Effective cost management is crucial for the financial viability of these projects, ensuring that they are completed on budget and operate efficiently.

Budgeting for Construction

Budgeting for construction is a critical aspect of cost management in cargo facility design. It involves detailed planning and estimation of costs for land acquisition, construction materials, labor, and equipment. A well-planned budget helps in avoiding cost overruns and ensures that the project stays financially viable.

According to industry experts, “A detailed budget that accounts for all aspects of construction is essential for the successful completion of cargo facility projects.”

“The key to successful budgeting is accurate forecasting and continuous monitoring of expenses.”

| Cost Component | Estimated Cost | Actual Cost |

|---|---|---|

| Land Acquisition | $1,000,000 | $1,050,000 |

| Construction Materials | $2,000,000 | $1,950,000 |

| Labor | $1,500,000 | $1,550,000 |

Operational Cost Efficiency

Achieving operational cost efficiency is vital for the long-term success of cargo facilities. This involves optimizing the use of resources, reducing waste, and implementing efficient operational practices. Strategies such as industrial space optimization can significantly reduce operational costs by maximizing the use of available space.

Implementing freight terminal construction planning best practices can also contribute to operational cost efficiency. This includes designing facilities with efficient workflow layouts and utilizing technology to streamline operations.

- Optimize storage solutions to reduce handling costs.

- Implement energy-efficient systems to lower utility bills.

- Use technology to automate processes and reduce labor costs.

By focusing on both budgeting for construction and achieving operational cost efficiency, cargo facility operators can ensure the financial viability and long-term success of their projects.

Enhancing Productivity in Cargo Facilities

To stay ahead in the logistics market, cargo facilities need to focus on enhancing their productivity. This involves streamlining operations, reducing costs, and improving customer satisfaction.

One effective way to achieve this is by applying lean management principles. Lean management is a methodology that aims to minimize waste and maximize value-added activities. In the context of cargo facilities, this could mean optimizing storage solutions, improving workflow efficiency, and reducing unnecessary movements.

Lean Management Principles

Lean management principles can be applied in various ways within cargo facilities. For instance, implementing a modular design concept can help in creating a flexible and efficient layout. This allows for easier adaptation to changing operational needs.

- Eliminating waste through efficient storage and handling practices

- Optimizing workflows to reduce processing times

- Implementing continuous improvement programs

Performance Metrics to Consider

To measure the effectiveness of productivity enhancements, cargo facilities need to track relevant performance metrics. These can include:

| Metric | Description | Benefit |

|---|---|---|

| Throughput | Measures the amount of cargo processed within a given timeframe | Helps in identifying bottlenecks and optimizing workflows |

| Inventory Turnover | Indicates how often inventory is sold and replaced within a period | Aids in managing inventory levels and reducing storage costs |

By focusing on these metrics and continually improving operations, cargo facilities can significantly enhance their productivity and competitiveness.

Case Studies in Successful Cargo Facility Design

Through the lens of successful case studies, we can understand the principles behind effective cargo facility design. By examining real-world examples, we gain insights into how different design elements contribute to the overall efficiency and productivity of cargo facilities.

Innovative Examples from the Industry

Several companies have made significant strides in cargo facility design, incorporating innovative solutions to enhance their operations. For instance, a leading logistics company implemented a modular design concept in their new warehouse, allowing for easier expansion and flexibility in storage solutions.

“The modular approach to our warehouse design has been a game-changer. It allows us to adapt quickly to changing customer demands without significant overhaul costs.” –

Another example is the use of advanced technology, such as automated storage and retrieval systems (AS/RS), which have significantly improved the efficiency of cargo handling. A case study on a major distribution center revealed that implementing AS/RS reduced labor costs by 30% and increased storage capacity by 25%.

| Feature | Traditional Design | Innovative Design |

|---|---|---|

| Modularity | Limited flexibility | Highly adaptable |

| Technology Integration | Basic mechanization | Advanced automation |

| Space Utilization | Suboptimal storage | Maximized storage capacity |

Lessons Learned from Implementation

Implementing successful cargo facility design requires careful planning and consideration of several factors. One key lesson is the importance of integrating technology from the outset. Facilities that incorporate advanced systems like warehouse management systems (WMS) and RFID tracking from the beginning tend to have smoother operations and better scalability.

Another crucial aspect is the consideration of future needs. Facilities designed with future expansion in mind, such as those using modular designs, are better positioned to adapt to growing demands without requiring costly renovations.

By studying these case studies, businesses can gain valuable insights into designing their own efficient and productive cargo facilities.

The Future of Cargo Facility Design

The future of cargo facility design is being influenced by several key factors, including automation, robotics, and e-commerce. As the logistics industry continues to evolve, the need for efficient, adaptable, and technologically advanced cargo facilities is becoming increasingly important.

Automation and Robotics

Automation and robotics are revolutionizing cargo facility design by enhancing operational efficiency and reducing labor costs. Automated Storage and Retrieval Systems (AS/RS) and robotic picking systems are being integrated into modern warehouses to streamline processes.

- Increased accuracy in order fulfillment

- Improved safety through reduced human intervention

- Enhanced scalability to meet growing demands

The incorporation of robotics in cargo facilities is also leading to innovative warehouse design solutions that maximize space utilization and flexibility.

E-commerce Influence

The rise of e-commerce has significantly impacted cargo facility design, with a growing need for facilities that can handle complex, multi-channel distribution networks. Logistics facility layout is being optimized to accommodate faster order processing and more flexible delivery options.

- Designing facilities with multi-channel distribution in mind

- Incorporating flexible storage solutions to adapt to changing demands

- Implementing advanced technology to enhance operational efficiency

As e-commerce continues to grow, the demand for sophisticated warehouse design solutions that can meet the challenges of modern logistics is expected to increase.

Conclusion: Building the Future of Cargo Facilities

As the industry continues to evolve, effective cargo facility design plays a crucial role in supply chain facility development. By maximizing space and productivity, businesses can stay ahead of the competition.

Best Practices Recap

Key takeaways from our exploration of cargo facility design include the importance of space efficiency, technology integration, and sustainable practices. Implementing modular design concepts, workflow analysis techniques, and lean management principles can significantly enhance operational efficiency.

Call to Action for Stakeholders

To drive innovation and excellence in cargo facility design, stakeholders must prioritize investment in automation, robotics, and energy-efficient solutions. By doing so, the industry can continue to adapt to the growing demands of e-commerce and global trade, ultimately shaping the future of supply chain facility development.