Can modern architecture achieve both sustainability and aesthetic appeal without compromising on structural integrity? The answer lies in glass engineering, a field that has revolutionized the way we design and construct buildings.

Glass materials have become a cornerstone in contemporary construction, offering unparalleled versatility and innovation. From the history of glassmaking to the latest advancements in structural glass design, understanding the principles of glass engineering is crucial for architects, engineers, and builders alike.

Key Takeaways

- Understanding the history and evolution of glass engineering.

- Exploring the different types of glass materials used in construction.

- Learning about the manufacturing processes that make structural glass design possible.

- Discovering the latest innovations in glass engineering.

- Applying best practices for incorporating glass into architectural designs.

Introduction to Glass Engineering

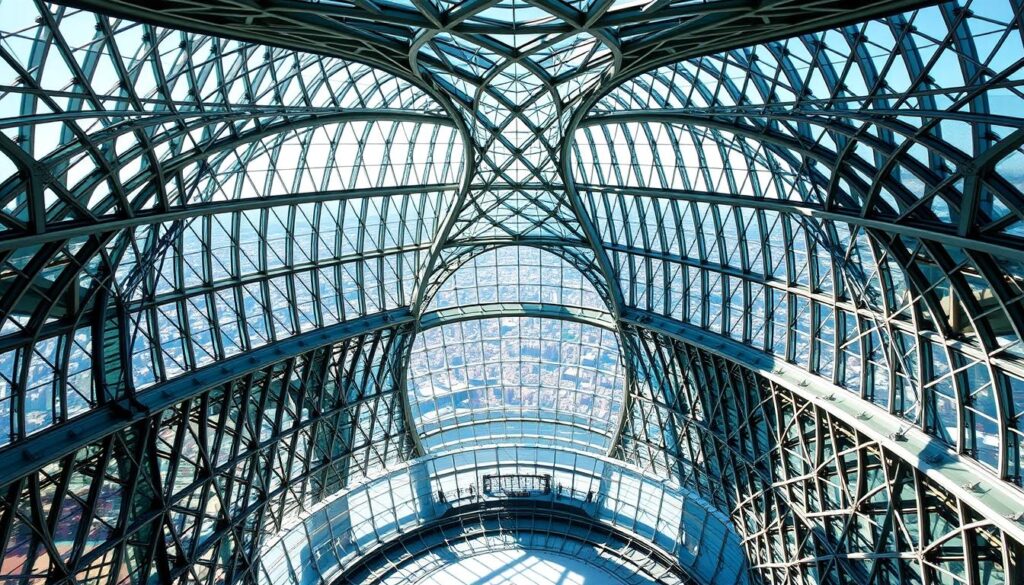

As a field that merges technology and aesthetics, glass engineering plays a vital role in creating sustainable and visually appealing structures. This discipline has become increasingly important in modern architecture, where the demand for innovative and functional glass solutions is on the rise.

What is Glass Engineering?

Glass engineering is a specialized field that involves the design, fabrication, and installation of glass components. It requires a deep understanding of the physical and chemical properties of glass, as well as the ability to apply this knowledge to create complex glass systems. The field is closely related to other engineering disciplines, such as materials science and civil engineering.

At its core, glass engineering is about balancing aesthetics with functionality. It involves selecting the appropriate type of glass for a specific application, considering factors such as strength, durability, and energy efficiency. For instance, glass engineering programs teach students how to analyze these factors and design glass systems that meet both functional and aesthetic requirements.

Importance in Modern Architecture

In modern architecture, glass engineering is crucial for creating buildings that are not only visually striking but also sustainable and energy-efficient. Glass facades, for example, can significantly impact a building’s energy consumption by controlling the amount of sunlight that enters the building. Moreover, advancements in glass technology have led to the development of smart glass, which can change its tint or opacity in response to environmental conditions, further enhancing energy efficiency.

| Benefits of Glass Engineering | Description |

|---|---|

| Aesthetic Appeal | Glass engineering allows for the creation of visually appealing structures that can enhance the architectural design of buildings. |

| Sustainability | By optimizing glass facades and using advanced glass technologies, glass engineering contributes to more sustainable and energy-efficient buildings. |

| Functional Versatility | Glass can be engineered to have various properties, such as self-cleaning or temperature control, making it a versatile material for different applications. |

The importance of glass engineering in modern architecture cannot be overstated. As buildings become more complex and the demand for sustainability increases, the role of glass engineers will continue to grow. By combining technical expertise with creative vision, glass engineers can create structures that are not only functional but also beautiful and sustainable.

History of Glass Engineering

From ancient Mesopotamia to modern-day skyscrapers, the evolution of glass engineering has been a remarkable journey. The history of glass engineering is replete with innovations that have transformed the way glass is used in construction and other fields.

Early Innovations in Glass

The earliest evidence of glass production dates back to around 2500 BCE in Mesopotamia. Initially, glass was used for making beads and other small objects. The Romans significantly advanced glassmaking techniques by discovering that by blowing air into molten glass, they could create a variety of shapes and forms.

Early innovations in glass were not limited to production techniques. The discovery of new glass materials and the development of glass processing technologies played a crucial role in expanding its applications. For instance, the addition of metallic oxides to glass allowed for the creation of colored glass, which became a hallmark of stained glass windows in medieval Europe.

The Evolution of Glass Techniques

Over the centuries, glass engineering has continued to evolve, driven by advances in glass manufacturing techniques. The Industrial Revolution marked a significant turning point with the introduction of mechanized glass production, enabling mass production and the development of new glass types.

| Period | Major Innovations | Impact on Glass Engineering |

|---|---|---|

| Ancient Mesopotamia | First glass production | Initial use of glass for beads and small objects |

| Roman Era | Glassblowing techniques | Creation of various glass shapes and forms |

| Industrial Revolution | Mechanized glass production | Mass production of glass, new glass types |

The evolution of glass techniques has also been influenced by advancements in other fields, such as materials science and nanotechnology. Today, glass engineering encompasses a wide range of disciplines, from smart glass technology to complex structural glazing systems.

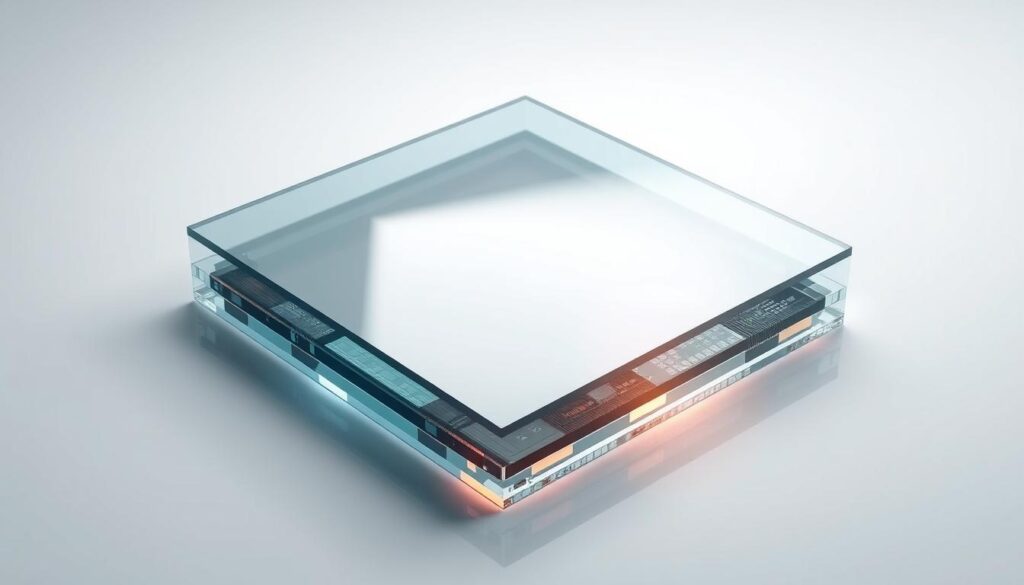

Types of Glass Used in Engineering

Glass engineering encompasses a variety of glass types, each with distinct properties and applications. The selection of glass type is crucial for the success of a project, as it affects the structure’s durability, safety, and aesthetic appeal.

Tempered Glass

Tempered glass, also known as toughened glass, is processed by heat treatment to increase its strength and durability. This type of glass is ideal for applications where safety is a concern, such as in architectural facades and vehicle windshields. Tempered glass can withstand significant stress and is less likely to break; however, when it does break, it shatters into small, blunt pieces to minimize injury.

Laminated Glass

Laminated glass is manufactured by sandwiching a layer of plastic, typically polyvinyl butyral (PVB), between two layers of glass. This construction enhances the glass’s security and sound insulation properties. Laminated glass is commonly used in skylights, glass floors, and windshields due to its ability to hold together even when broken, thus providing additional safety.

For more information on the different types of glass and their applications, you can visit https://waspecialprojects.com.au/types-of-glass/.

Insulated Glass

Insulated glass units (IGUs) consist of two or more glass panes separated by a spacer, creating a gap that is filled with air or gas. This design significantly improves the thermal insulation of the glass, reducing heat transfer and energy loss. Insulated glass is widely used in energy-efficient building designs to minimize heating and cooling costs.

The choice of glass type in engineering depends on various factors, including the intended application, environmental conditions, and required performance characteristics. Advances in glass innovation research continue to expand the possibilities for glass materials in construction and other fields, enhancing their strength, functionality, and sustainability.

Properties of Glass

Glass is a versatile material that exhibits a range of properties making it suitable for various engineering applications. The unique combination of properties in glass materials makes them an ideal choice for a wide range of projects, from construction to electronics.

Optical Properties

Glass is known for its excellent optical properties, including transparency, reflectivity, and the ability to transmit light with minimal distortion. These properties make glass an essential material in the manufacture of windows, lenses, and optical fibers. For instance, glass used in optical fibers is designed to have specific optical properties that enable efficient data transmission over long distances.

The optical properties of glass can be tailored through various glass processing technologies, such as doping with other materials or applying special coatings. This allows for the creation of glass with specific optical characteristics, such as filters or mirrors.

Mechanical Properties

The mechanical properties of glass, including its strength, hardness, and resistance to deformation, are critical in determining its suitability for different applications. While glass is often perceived as brittle, advancements in glass engineering have led to the development of stronger and more durable glass materials.

- Tempering: A process that increases the strength of glass by inducing compressive stresses on its surface.

- Laminating: A technique that involves sandwiching a layer of material, usually PVB, between two glass panes to enhance safety and durability.

These mechanical properties are crucial in applications where glass is subjected to stress, such as in structural glass engineering projects.

Thermal Properties

Glass also exhibits unique thermal properties, including its ability to withstand extreme temperatures and its resistance to thermal shock. The thermal properties of glass are influenced by its composition and processing history.

In sustainable glass engineering, the thermal properties of glass are leveraged to create energy-efficient buildings. For example, double-glazed windows reduce heat transfer between the inside and outside of a building, thereby reducing energy consumption.

Understanding the properties of glass is essential for engineers to harness its potential in various applications. By tailoring the properties of glass through advanced processing technologies, engineers can create materials that meet specific requirements for optical, mechanical, and thermal performance.

Manufacturing Processes in Glass Engineering

The art of glass manufacturing encompasses several critical steps, from the initial melting of raw materials to the final annealing process. Understanding these processes is essential for producing high-quality glass that meets the demands of modern architecture and engineering.

Glass Melting

Glass melting is the first step in the manufacturing process, where raw materials such as silica sand, soda ash, and limestone are heated to extremely high temperatures until they melt and form a molten glass. This process is crucial as it determines the chemical composition and clarity of the final product.

Key factors in glass melting include:

- Temperature control: Maintaining the optimal temperature is vital for achieving the desired glass properties.

- Raw material quality: The purity and consistency of raw materials directly impact the quality of the molten glass.

- Fuel efficiency: Modern glass manufacturing facilities are focusing on energy-efficient melting processes to reduce production costs and environmental impact.

Forming Techniques

Once the glass is molten, it is formed into the desired shape using various techniques. Common forming methods include float glass production, blowing, and pressing. Each method has its advantages and is suited for different types of glass products.

The float glass process, for instance, involves floating the molten glass on a bath of molten tin, where it spreads out and forms a flat, smooth surface. This method is widely used for producing large, flat glass sheets for architectural and automotive applications.

Annealing Process

The annealing process is a critical step that involves slowly cooling the glass over a controlled period to prevent stresses and breakage. Annealing furnaces are used to heat the glass to a specific temperature and then gradually cool it down.

Annealing is important because it:

| Benefits | Description |

|---|---|

| Reduces Stress | Prevents internal stresses that could lead to cracking or shattering. |

| Improves Durability | Enhances the overall durability and longevity of the glass. |

| Increases Safety | Makes the glass safer for use in construction and other applications. |

In conclusion, the manufacturing process of glass involves intricate steps that require precision and control. By understanding and optimizing these processes, manufacturers can produce high-quality glass that meets the evolving needs of the construction and engineering industries.

Design Principles for Glass Structures

Effective glass structure design hinges on a thorough understanding of the interplay between aesthetics, structural requirements, and environmental considerations. As architects and engineers strive to create innovative glass structures, they must balance these competing demands to produce buildings that are both visually striking and functionally sound.

Aesthetic Considerations

The aesthetic appeal of glass structures is a significant factor in their popularity. Glass can be used to create sleek, modern facades that reflect light and surroundings, adding to the visual appeal of a building. Structural glass design involves not just selecting the right type of glass, but also considering how it will be used to create the desired visual effect.

For instance, the use of laminated glass can provide a sense of continuity and transparency, while also offering enhanced safety features. Architects can also experiment with different glass colors and textures to achieve the desired aesthetic. As noted in a study on glass engineering, “the aesthetic potential of glass is vast, and its use can significantly enhance the visual appeal of a structure” Report 1025.

Structural Integrity

While aesthetics are crucial, the structural integrity of glass structures is equally important. Glass facade engineering requires a deep understanding of how glass behaves under various loads and stresses. Engineers must consider factors such as wind resistance, thermal stress, and impact resistance when designing glass facades.

- Ensure that the glass is properly supported and framed to withstand external forces.

- Use advanced software to simulate and analyze the behavior of glass under different conditions.

- Conduct rigorous testing to validate the design and ensure compliance with relevant standards.

Sustainability in Design

Sustainable glass engineering is becoming increasingly important as architects and builders seek to reduce the environmental impact of their projects. This involves not just selecting eco-friendly materials, but also designing structures that maximize natural light and minimize energy consumption.

“Sustainable design is not just about using sustainable materials, but also about creating buildings that are energy-efficient and minimize environmental impact.”

To achieve sustainability in glass design, architects can use techniques such as:

- Using recycled glass or glass with a high recycled content.

- Designing buildings that maximize natural daylight, reducing the need for artificial lighting.

- Specifying glass with low-e coatings to improve thermal performance.

By integrating these principles, architects and engineers can create glass structures that are not only visually stunning but also structurally sound and environmentally friendly.

Applications of Glass in Construction

In contemporary architecture, glass plays a crucial role in enhancing both functionality and aesthetics. Its versatility and the advancements in glass processing technologies have made it a staple in modern construction projects.

Facades and Curtain Walls

Glass facades and curtain walls are among the most prominent applications of glass in construction. They not only provide a sleek, modern appearance but also offer energy efficiency and natural lighting. The use of advanced glass materials and coatings can significantly improve a building’s thermal performance.

Windows and Skylights

Windows and skylights are critical elements where glass is used extensively. They allow natural light to penetrate deep into buildings, reducing the need for artificial lighting. Modern glass technologies, such as double or triple glazing, enhance thermal insulation, contributing to energy savings.

Interior Partitions

Glass is also widely used for interior partitions, offering a sense of openness while maintaining separation between spaces. It can be used to create private areas without compromising on natural light. The use of tempered glass or laminated glass for interior partitions adds an extra layer of safety.

The applications of glass in construction are vast and varied, driven by advancements in glass engineering and processing technologies. As architects and builders continue to push the boundaries of design and functionality, the role of glass is likely to become even more significant.

Innovations in Glass Engineering

The glass engineering field is on the cusp of a revolution, driven by innovations such as smart glass technology, nanotechnology, and 3D printing. These advancements are not only enhancing the properties of glass but also expanding its applications across various industries.

Smart Glass Technology

Smart glass technology is a significant innovation that allows glass to change its properties in response to environmental conditions. This technology can switch from transparent to opaque, control light transmission, and even generate energy. Electrochromic glass is a type of smart glass that changes its tint in response to an electric current, making it ideal for energy-efficient buildings.

Nanotechnology in Glass

Nanotechnology is being used to enhance the properties of glass by incorporating nanoparticles that improve its strength, durability, and optical properties. For instance, nanoscale coatings can be applied to glass to make it self-cleaning or to improve its thermal insulation properties.

3D Printed Glass

The advent of 3D printing technology has opened new avenues for glass engineering. 3D printed glass allows for the creation of complex geometries and customized designs that were previously impossible to achieve with traditional manufacturing techniques. This technology is particularly useful for creating bespoke architectural features and artistic installations.

These innovations in glass engineering are poised to transform the industry by providing new functionalities, improving sustainability, and enabling the creation of complex designs. As research continues to advance, we can expect to see even more exciting developments in the field.

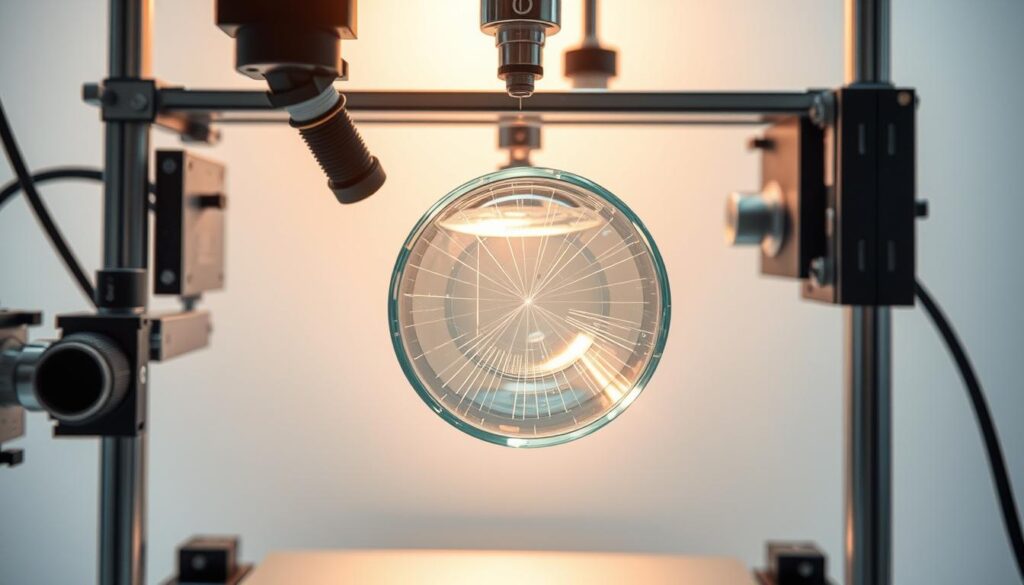

Testing and Quality Control

The reliability and performance of glass materials depend heavily on rigorous testing and quality control. Ensuring that glass products meet the required standards is crucial for their application in various industries, particularly in construction where safety and durability are paramount.

Importance of Quality Assurance

Quality assurance in glass engineering involves a series of processes designed to verify that the glass products conform to specified requirements. This includes glass strength analysis, which is critical for understanding how glass will perform under different conditions. For more information on quality assurance in commercial glazing, visit Giroux Glass.

Common Testing Methods

Several testing methods are employed to evaluate the properties of glass, including:

- Impact resistance testing

- Thermal stress testing

- Optical property testing

These tests help in assessing the suitability of glass for various applications, from facades and curtain walls to windows and skylights. The data obtained from these tests are crucial for manufacturers and engineers to ensure that the glass products will perform as expected under real-world conditions.

Standards and Certifications

Adherence to industry standards and obtaining relevant certifications are vital for glass manufacturers. Standards such as those provided by the American Society for Testing and Materials (ASTM) offer guidelines for testing and evaluating glass products. For instance, project management in civil engineering, which often involves glass installation, requires adherence to these standards to ensure quality and safety, as discussed on World Civil Society.

Certifications like those from the Glass Association of North America (GANA) further validate a manufacturer’s commitment to quality. These standards and certifications play a significant role in maintaining the integrity of glass processing technologies and ensuring that the final products meet the necessary quality benchmarks.

Challenges in Glass Engineering

As glass continues to be a pivotal material in modern architecture and construction, engineers are tasked with overcoming significant challenges related to its durability, environmental sustainability, and cost-effectiveness. The multifaceted nature of these challenges necessitates a comprehensive approach to ensure the successful application of glass in various projects.

Fragility vs. Strength

One of the primary challenges in glass engineering is balancing the material’s inherent fragility with the need for strength. Glass is prone to cracking and shattering under impact, which can compromise the structural integrity of a building or structure. To address this, engineers employ various techniques, such as glass strength analysis, to enhance the durability of glass components.

The use of advanced glass materials, including tempered and laminated glass, has become a standard practice to improve strength. For instance, tempered glass undergoes a thermal treatment process that increases its resistance to thermal stress and impact. Laminated glass, on the other hand, involves sandwiching a layer of plastic between glass layers, enhancing its ability to withstand impact without shattering.

Environmental Factors

Environmental factors pose another significant challenge in glass engineering. Glass structures are exposed to various environmental conditions, including temperature fluctuations, wind, and seismic activity. These factors can affect the performance and longevity of glass components. For example, thermal stress caused by temperature variations can lead to glass breakage if not properly managed.

To mitigate these effects, engineers must consider the environmental conditions of the project’s location during the design phase. This includes selecting appropriate glass types and designing structures that can accommodate movements and stresses caused by environmental factors. The integration of sustainable glass engineering practices also plays a crucial role in minimizing the environmental footprint of glass production and application.

Cost Considerations

Cost is a critical factor in glass engineering, as the material and manufacturing processes can be expensive. The cost of advanced glass technologies, such as smart glass and insulated glass units, can be particularly high. However, these technologies often provide long-term benefits, including energy savings and reduced maintenance costs.

A detailed analysis of the cost-benefit ratio is essential for determining the feasibility of various glass solutions. The following table provides a comparative analysis of different glass types and their associated costs:

| Glass Type | Cost per Square Foot | Energy Efficiency | Durability |

|---|---|---|---|

| Tempered Glass | $5-$10 | Medium | High |

| Laminated Glass | $10-$20 | High | Very High |

| Insulated Glass | $15-$30 | Very High | High |

For more information on innovative glass applications, visit architectural vision with structural glass.

Health and Safety in Glass Engineering

Health and safety protocols are crucial in the realm of glass engineering. Ensuring a safe working environment not only protects the workforce but also enhances the overall quality of the glass products.

Handling Glass Safely

Handling glass safely is a critical aspect of health and safety in glass engineering. Workers must be trained to handle glass materials with care to prevent injuries. This includes using appropriate personal protective equipment (PPE) such as gloves and goggles.

The use of tempered glass and laminated glass requires special handling techniques due to their unique properties. For instance, tempered glass is more prone to shattering, while laminated glass can be more challenging to cut without causing damage.

| Glass Type | Handling Precautions | Safety Measures |

|---|---|---|

| Tempered Glass | Handle with care to avoid shattering | Use gloves and goggles |

| Laminated Glass | Avoid cutting without proper tools | Use cutting mats and safety glasses |

| Insulated Glass | Prevent moisture exposure | Store in dry conditions |

Fire Safety Standards

Fire safety is another vital aspect of health and safety in glass engineering. Glass materials can behave differently under high temperatures, and understanding these behaviors is crucial for maintaining fire safety standards.

Fire-resistant glass is often used in applications where fire safety is a concern. This type of glass is designed to withstand high temperatures without shattering, thereby preventing the spread of fire.

Compliance with Regulations

Compliance with health and safety regulations is mandatory in the glass engineering industry. This includes adhering to standards set by regulatory bodies such as OSHA (Occupational Safety and Health Administration) in the United States.

Regular audits and training programs are essential to ensure that all employees are aware of and comply with these regulations. This not only ensures a safe working environment but also helps in avoiding legal repercussions.

- Conduct regular safety audits

- Provide ongoing training to employees

- Maintain records of compliance

By prioritizing health and safety, the glass engineering industry can continue to innovate while protecting its workforce and the environment.

Future Trends in Glass Engineering

Sustainable practices, technological advancements, and material integration are expected to shape the future of glass engineering. As the industry continues to evolve, these trends will play a crucial role in determining the direction of glass engineering.

Sustainable Practices

The adoption of sustainable glass engineering practices is becoming increasingly important. This includes the use of recycled glass, reducing waste, and implementing energy-efficient manufacturing processes. For instance, some manufacturers are now using solar-powered furnaces to melt glass, significantly reducing their carbon footprint.

Moreover, research into structural glass design is leading to more efficient use of materials, minimizing waste and maximizing structural integrity.

Technological Advancements

Glass innovation research is driving technological advancements in the field. One significant area of development is in smart glass technology, which can change its opacity or color in response to environmental conditions. This technology has numerous applications, from energy-efficient windows to privacy glass for interior partitions.

Another area of innovation is in glass processing technologies, where advancements are being made in techniques such as 3D printing and nanotechnology. These technologies enable the creation of complex glass structures and components with unique properties.

Integration with Other Materials

The integration of glass with other materials is opening up new possibilities for glass engineering. By combining glass with materials like metals, polymers, or ceramics, engineers can create composite materials with enhanced properties. For example, laminating glass with polymers can improve its impact resistance and safety.

This integration is not only limited to material properties but also extends to aesthetic and functional applications, enabling the creation of innovative designs that were previously not possible.

Case Studies in Glass Engineering

Examining successful glass engineering projects provides valuable insights into its practices. By analyzing both the successes and failures in the field, we can better understand the complexities and innovations that define modern glass engineering.

Notable Glass Structures

Several glass structures around the world have become icons of architectural innovation. For instance, the Apple Store in New York City features a stunning glass cube that has become a landmark. This structure showcases advancements in glass facade engineering and structural glass design.

- The Guggenheim Museum in Bilbao, Spain, with its undulating glass facade.

- The Crystal Palace in London, a historic example of innovative glass construction.

- The Louvre Pyramid in Paris, featuring a striking glass structure.

Lessons Learned from Failures

Failures in glass engineering projects often provide critical lessons that improve future designs. For example, the collapse of a glass roof in a public building can highlight the importance of proper structural glass design and safety protocols.

- Inadequate testing procedures can lead to structural failures.

- Poor material selection can compromise the integrity of glass structures.

- Insufficient maintenance can lead to premature degradation.

Innovative Designs

Innovation is at the heart of glass engineering, with new technologies and materials continually being developed. Smart glass technology and nanotechnology in glass are areas that are seeing significant research and development, enabling the creation of more efficient, sustainable, and functional glass structures.

Some of the key areas of glass innovation research include:

- Improving the thermal properties of glass.

- Developing more durable and resistant glass materials.

- Integrating technology into glass for smart applications.

By examining these case studies and the lessons they provide, we can gain a deeper understanding of the current state and future potential of glass engineering.

Educational Pathways in Glass Engineering

A career in glass engineering is built on a foundation of relevant academic programs, specialized training, and active participation in professional organizations. As the field continues to evolve, it is essential for aspiring glass engineers to have access to comprehensive educational resources.

Academic Programs in Glass Engineering

Several academic programs cater to the needs of students interested in glass engineering. These include:

- Materials Science and Engineering programs that focus on the properties and applications of glass.

- Mechanical Engineering programs with a specialization in materials processing and manufacturing.

- Architecture and Civil Engineering programs that cover the use of glass in construction.

These programs provide a solid foundation in the principles of glass engineering, including glass materials and glass processing technologies.

Certifications and Training

Beyond academic degrees, certifications and specialized training programs play a crucial role in the professional development of glass engineers. These programs offer hands-on experience and in-depth knowledge of specific aspects of glass engineering, such as:

- Glass fabrication and processing techniques.

- Safety protocols and standards in glass handling.

- Advanced technologies in glass manufacturing.

Certifications from recognized bodies can significantly enhance a professional’s credibility and career prospects in the field.

Professional Organizations

Active participation in professional organizations is vital for glass engineers to stay updated on the latest developments and network with peers. Organizations such as the Glass Association and the International Association of Glass Engineers provide valuable resources, including conferences, workshops, and publications.

These organizations not only support the professional growth of their members but also contribute to the advancement of glass engineering as a discipline.

Conclusion and Future Outlook

The field of glass engineering is on the cusp of a revolution, driven by advances in glass innovation research and the adoption of sustainable glass engineering practices. As we have explored in this comprehensive guide, the integration of new technologies and methodologies is transforming the way glass is designed, manufactured, and applied in various industries.

Innovation in Glass Processing

Continuous innovation in glass processing technologies is crucial for the development of new glass products and applications. The evolving role of glass engineers will be shaped by their ability to harness these innovations, ensuring that glass continues to play a vital role in modern architecture and construction.

Evolving Role of Glass Engineers

As the field continues to evolve, glass engineers will need to stay abreast of the latest developments in sustainable glass engineering and glass processing technologies. By doing so, they will be able to drive the creation of innovative, efficient, and sustainable glass solutions that meet the demands of a rapidly changing world.