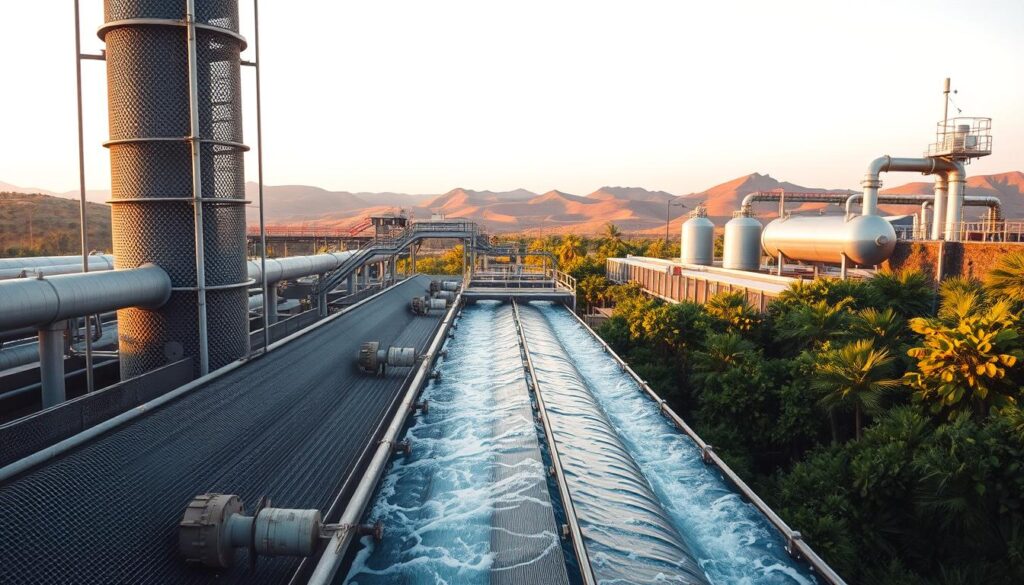

Can we turn the world’s most abundant resource into a reliable source of fresh water? As the global demand for fresh water continues to rise, water desalination technology is emerging as a vital solution to address the pressing issue of water scarcity.

The process of seawater desalination involves several complex steps, from intake to post-treatment. For those looking to understand the intricacies of designing a desalination system, it’s crucial to grasp the engineering essentials that make it all work.

This article aims to provide a comprehensive guide on the key components involved in designing an efficient desalination system, highlighting the importance of each stage in the process.

Key Takeaways

- Understanding the global need for fresh water and the role of desalination.

- The essential components involved in the seawater desalination process.

- The importance of pretreatment and post-treatment systems.

- The role of energy recovery devices in reducing operational costs.

- Best practices for designing an efficient desalination system.

Introduction to Desalination Plant Engineering

As the world grapples with water scarcity, desalination plant engineering emerges as a key solution. Desalination, the process of removing salt and other minerals from seawater or brackish water, is crucial for providing fresh water in many regions around the globe.

Importance of Desalination

Desalination is vital for addressing water scarcity, especially in coastal areas where access to traditional freshwater sources is limited. The process helps in augmenting the available water resources, supporting both domestic needs and industrial applications.

The significance of desalination can be seen in several areas:

- Providing drinking water for communities in arid regions

- Supporting agricultural needs by supplying water for irrigation

- Enabling industrial processes that require large volumes of water

Overview of Desalination Technologies

There are several desalination technologies employed worldwide, each with its unique advantages and applications. The primary methods include:

- Reverse Osmosis (RO): This is one of the most common methods, involving the forced passage of seawater through semi-permeable membranes to filter out salt and other impurities.

- Multi-Stage Flash Distillation (MSF): This process involves heating seawater under pressure to produce steam, which is then condensed into fresh water. It’s a widely used method in the Middle East.

- Electrodialysis (ED): This technique uses electrical currents to remove salt from water, passing it through ion-selective membranes.

The choice of desalination technology depends on various factors including energy availability, feed water quality, and local environmental conditions.

Types of Desalination Processes

With the increasing demand for fresh water, understanding the different types of desalination processes has become crucial. Desalination, the process of removing salt and other minerals from seawater or brackish water, is achieved through various technologies. Each method has its operational principles, advantages, and limitations, making some more suitable for specific applications than others.

Reverse Osmosis

Reverse osmosis (RO) is one of the most widely used desalination methods. It involves forcing seawater through a semi-permeable membrane, which filters out salts and other impurities, producing fresh water. The process is energy-intensive but has become more efficient with advancements in membrane technology. For more information on reverse osmosis and its applications, visit IDE Technologies, a leading provider of seawater desalination solutions.

Multi-Stage Flash Distillation

Multi-stage flash distillation (MSF) is another prominent desalination technology. It involves heating seawater under pressure to produce steam, which is then condensed into fresh water. This process is repeated across multiple stages, hence the name. MSF is particularly effective for large-scale desalination plants due to its ability to handle high volumes of seawater.

Electrodialysis

Electrodialysis (ED) is a desalination process that uses electrical currents to remove salt from water. It involves the use of ion-selective membranes that allow either positively or negatively charged ions to pass through, effectively separating salt from water. ED is particularly useful for treating brackish water and has the advantage of being more energy-efficient for certain types of feed water.

Understanding these different desalination processes is essential for selecting the most appropriate technology for a given application. Whether it’s reverse osmosis desalination, multi-stage flash distillation, or electrodialysis, each method has its place in addressing the global need for fresh water through saline water treatment.

Key Components of a Desalination Plant

Understanding the key components of a desalination plant is crucial for its successful operation. A desalination plant’s effectiveness relies on the integration of several critical systems that work together to produce clean water.

Pre-treatment Systems

Pre-treatment systems are a vital part of any desalination plant. These systems are designed to remove larger particles and contaminants from the seawater before it undergoes desalination, protecting the plant’s equipment and improving overall efficiency.

- Removal of larger debris and sediments

- Adjustment of pH levels to prevent scaling

- Addition of chemicals to prevent biological growth

Pre-treatment is essential for maintaining the longevity of the desalination equipment and ensuring the quality of the water produced.

Desalination Units

The desalination units are the core of the plant, where the actual process of removing salt and other minerals from the seawater takes place. Technologies such as reverse osmosis and multi-stage flash distillation are commonly used.

The choice of desalination technology depends on various factors, including the size of the plant, the quality of the feed water, and the energy requirements.

Post-treatment Equipment

After desalination, the water may still require additional treatment to meet drinking water standards. Post-treatment equipment is used to adjust the water quality, making it safe for consumption.

- Remineralization to add back beneficial minerals

- Disinfection to kill any remaining bacteria or viruses

- Adjustment of pH levels for palatability

Post-treatment is crucial for ensuring that the water is not only clean but also safe and pleasant to drink.

In conclusion, the key components of a desalination plant work together to produce clean, safe drinking water. By understanding and optimizing these components, operators can improve the efficiency and effectiveness of their desalination plants.

Site Selection and Environmental Considerations

Desalination plant site selection is a complex process that requires careful consideration of multiple factors to ensure minimal environmental impact. The location of a desalination plant can significantly affect its operational efficiency, environmental sustainability, and overall cost.

Understanding Site Assessments

Site assessments are vital for understanding the environmental conditions and potential impacts of a desalination plant. These assessments involve evaluating the local ecosystem, water intake and discharge locations, and potential effects on marine life. A thorough site assessment helps in identifying potential risks and opportunities for mitigating environmental impacts.

For instance, a study on the impacts of desalination plants highlights the importance of careful site selection. According to a report by Roberts et al., the environmental impact of desalination can be significant if not properly managed the effects of desalination on marine.

Evaluating Environmental Impact

Evaluating the environmental impact of a desalination plant involves assessing its effects on local ecosystems, including marine life and water quality. This evaluation is crucial for developing strategies to mitigate adverse effects, such as implementing advanced water treatment technologies or designing intake and discharge systems that minimize harm to marine organisms.

The environmental impact assessment should also consider the energy consumption of the desalination process and its carbon footprint. By understanding these factors, plant operators can explore options for reducing energy use and greenhouse gas emissions, thereby enhancing the sustainability of the desalination plant.

Efficient site selection and environmental impact assessment are critical for the successful operation of a desalination plant. By carefully evaluating these factors, developers can ensure that their projects are both economically viable and environmentally sustainable.

Regulatory Standards and Compliance

Regulatory compliance is a critical aspect of desalination plant engineering, involving adherence to a myriad of standards that govern operational safety and environmental stewardship. Desalination plants, being complex industrial facilities, are subject to a wide range of regulations that vary by country and region.

Overview of Regulatory Bodies

Regulatory bodies play a crucial role in overseeing the operation of desalination plants. These organizations are responsible for setting and enforcing standards related to water quality, environmental impact, and operational safety. In the United States, for example, the Environmental Protection Agency (EPA) is a key regulatory body that sets national standards for drinking water quality, including water produced by desalination plants.

Key Regulatory Bodies:

- Environmental Protection Agency (EPA)

- World Health Organization (WHO)

- Local and State Environmental Agencies

Key Standards to Follow

Desalination plants must comply with a variety of standards to ensure they operate safely and with minimal environmental impact. These standards cover aspects such as water quality, waste management, and energy consumption.

Key Standards for Desalination Plants:

| Standard | Description | Regulatory Body |

|---|---|---|

| Drinking Water Quality Standards | Sets limits on contaminants in drinking water | EPA |

| Effluent Guidelines | Regulates the discharge of wastewater | EPA, Local Agencies |

| Environmental Impact Assessments | Requires assessment of potential environmental impacts | WHO, Local Agencies |

Compliance with these standards is not only a legal requirement but also essential for ensuring the long-term sustainability of desalination as a source of freshwater.

Water Quality and Testing Requirements

Water quality monitoring is a vital component of desalination plant operation, guaranteeing the water is safe for consumption. Effective monitoring ensures that the water produced meets or exceeds the required standards for drinking water.

The process involves regular testing for various parameters to ensure the water is safe for public consumption. According to guidelines from regulatory bodies such as the Texas Commission on Environmental Quality, comprehensive water quality testing is crucial. For detailed information, refer to the guidance document on water quality standards.

Importance of Water Quality Monitoring

Monitoring water quality is essential for identifying potential contaminants and ensuring that the treatment process is functioning correctly. It helps in detecting issues early, allowing for prompt corrective actions to be taken.

Regular water quality monitoring also aids in maintaining compliance with regulatory standards, thereby avoiding legal and financial repercussions. Moreover, it enhances public trust in the water supply by demonstrating a commitment to providing safe drinking water.

Key Testing Parameters

Key parameters for water quality testing in desalination plants include salinity, pH levels, presence of heavy metals, and microbial contaminants. These parameters are critical in assessing the effectiveness of the desalination process and the quality of the produced water.

- Salinity: Ensuring that the water is not too saline for consumption.

- pH Levels: Verifying that the water’s pH is within the acceptable range for drinking water.

- Presence of Contaminants: Testing for heavy metals, bacteria, and other potential contaminants.

By focusing on these key parameters, desalination plants can ensure that the water they produce is safe and meets the required standards. Regular testing and monitoring are indispensable components of a robust water quality management system.

Energy Consumption and Efficiency

Energy consumption is a critical factor in the operation of desalination plants worldwide. Desalination is an energy-intensive process, and the choice of energy source can significantly impact the plant’s carbon footprint.

Energy Sources for Desalination

Desalination plants can be powered by various energy sources, including fossil fuels, nuclear energy, and renewable energy sources like solar and wind power. The choice of energy source affects not only the operational costs but also the environmental impact of the plant.

Traditionally, many desalination plants have relied on fossil fuels, which are abundant but contribute to greenhouse gas emissions. However, there’s a growing shift towards renewable energy sources to power desalination plants, reducing their carbon footprint.

Innovations in Energy Efficiency

Innovations in energy recovery devices and more efficient membranes are significantly improving the energy efficiency of desalination plants. Energy recovery devices can recover up to 90% of the energy used in the desalination process, substantially reducing the overall energy consumption.

| Energy Source | Carbon Footprint | Cost |

|---|---|---|

| Fossil Fuels | High | Variable |

| Renewable Energy | Low | Decreasing |

| Nuclear Energy | Low | High |

The shift towards more energy-efficient technologies and renewable energy sources is crucial for reducing the environmental impact of desalination plants. As the demand for freshwater continues to grow, innovations in energy efficiency will play a vital role in making desalination a more sustainable option.

Economic Feasibility and Cost Analysis

Desalination projects require thorough economic analysis to ensure feasibility. The construction and operation of desalination plants involve significant financial investments, making it essential to assess the economic viability of such projects.

Cost Components of Desalination Plants

The cost of establishing and operating a desalination plant can be broken down into several key components. These include:

- Capital Costs: Initial investment in infrastructure, equipment, and technology.

- Operational Costs: Expenses related to energy consumption, labor, and maintenance.

- Maintenance Costs: Ongoing expenditures for upkeep and replacement of parts.

Understanding these cost components is crucial for accurate budgeting and financial planning. The table below provides a breakdown of typical costs associated with desalination plants.

| Cost Component | Description | Estimated Cost Range |

|---|---|---|

| Capital Costs | Infrastructure, equipment, technology | $500 million – $1 billion |

| Operational Costs | Energy, labor, maintenance | $0.50 – $1.50 per cubic meter of water |

| Maintenance Costs | Upkeep, replacement parts | 5% – 10% of capital costs annually |

Financing Options for Projects

Financing desalination projects can be achieved through various channels. These include:

- Private Investment: Funding from private investors and companies.

- Government Funding: Grants and subsidies provided by government agencies.

- Public-Private Partnerships (PPPs): Collaborative financing models between public and private entities.

Each financing option has its advantages and challenges. A combination of these options can be used to secure the necessary funding for desalination projects.

Advances in Desalination Technology

Advances in desalination technology are paving the way for more efficient, cost-effective, and environmentally friendly water production methods. The industry is continually evolving, driven by the need for sustainable solutions to global water scarcity.

Innovative Materials and Membranes

The development of new materials and membranes is crucial for improving the efficiency of desalination processes. Innovative membrane technologies, such as graphene-based membranes and biomimetic membranes, offer enhanced permeability, selectivity, and durability. These advancements are reducing energy consumption and increasing the overall efficiency of desalination plants.

- Graphene-based membranes provide improved permeability and selectivity.

- Biomimetic membranes mimic natural processes to enhance desalination efficiency.

- Nanocomposite membranes offer enhanced durability and resistance to fouling.

Smart Desalination Systems

The integration of smart technologies such as IoT and AI is transforming desalination plants into highly efficient and optimized systems. Smart desalination systems can monitor and adjust operations in real-time, predict maintenance needs, and optimize energy consumption.

- IoT sensors enable real-time monitoring of plant operations.

- AI algorithms predict maintenance needs and optimize performance.

- Data analytics improve decision-making and operational efficiency.

These advancements are not only improving the efficiency and sustainability of desalination plants but also reducing operational costs. As the industry continues to evolve, we can expect to see even more innovative solutions emerge.

Maintenance and Operational Considerations

To ensure the smooth operation of a desalination plant, maintenance and operational considerations are paramount. The longevity and efficiency of the plant depend on a well-planned maintenance schedule and the ability to troubleshoot common issues promptly.

Routine Maintenance Practices

Regular maintenance is essential to prevent equipment wear and tear, ensuring the plant operates at optimal levels. This includes:

- Daily inspections of equipment and membranes

- Regular cleaning and replacement of filters

- Periodic checks on pumps and valves

- Monitoring of system performance and water quality

Membrane maintenance is particularly critical, as membranes are prone to fouling. Regular cleaning and monitoring can help prevent this issue.

Troubleshooting Common Issues

Despite regular maintenance, issues can still arise. Common problems include membrane fouling, equipment failure, and system downtime. Effective troubleshooting involves:

- Identifying the root cause of the issue

- Implementing corrective actions

- Conducting follow-up inspections to ensure the issue is resolved

A comprehensive understanding of the plant’s systems and equipment is crucial for efficient troubleshooting. Training personnel on troubleshooting techniques can significantly reduce downtime.

| Maintenance Activity | Frequency | Purpose |

|---|---|---|

| Equipment Inspection | Daily | Identify potential issues early |

| Filter Cleaning/Replacement | Weekly/Monthly | Ensure water quality and system efficiency |

| Membrane Cleaning | Quarterly | Prevent membrane fouling |

Public Perception and Community Engagement

Desalination projects require not only technological advancements but also strong public support. The success of such projects heavily relies on how they are perceived by the public and the level of community engagement.

Educating the Community

Educating the community about the benefits and processes of desalination is crucial. This involves transparent communication about the project’s goals, environmental impact, and economic benefits. By doing so, communities are more likely to support desalination initiatives.

According to a study on social issues and public acceptance of seawater desalination plants, public acceptance is influenced by factors such as trust in the operating company and perceived environmental. Therefore, fostering trust through education and transparency is key.

Addressing Public Concerns

Addressing public concerns is another vital aspect of community engagement. Common concerns include the environmental impact, energy consumption, and cost of desalinated water. By providing clear, factual information and demonstrating a commitment to mitigating these issues, projects can gain broader acceptance.

Effective community engagement strategies include public forums, informational campaigns, and collaborative decision-making processes. These approaches help in building a positive relationship between the project developers and the community.

By focusing on education and addressing concerns, desalination projects can improve their public image and increase their chances of success. It’s about creating a dialogue and ensuring that the community feels involved and informed throughout the process.

Future Trends in Desalination

The desalination industry is on the cusp of a revolution, driven by emerging technologies that promise to enhance efficiency and reduce environmental impact. As we look to the future, it’s clear that desalination will play an increasingly important role in addressing global water scarcity.

Emerging Technologies in the Field

One of the most significant emerging technologies in desalination is the development of advanced membrane materials. These new membranes offer improved permeability, durability, and resistance to fouling, which can significantly reduce the energy required for desalination and increase the overall efficiency of the process.

Renewable energy integration is another key trend shaping the future of desalination. By harnessing solar, wind, and other forms of renewable energy, desalination plants can reduce their reliance on fossil fuels, lowering their carbon footprint and operational costs.

Predictions for the Industry

Industry predictions suggest that the desalination market will experience significant growth in the coming years, driven by increasing water demand and the need for sustainable solutions. As technology continues to evolve, we can expect to see more efficient, cost-effective, and environmentally friendly desalination solutions.

The adoption of smart desalination systems is expected to become more widespread, leveraging data analytics, IoT sensors, and AI to optimize plant operations and maintenance. This will not only improve the efficiency of desalination plants but also enhance their reliability and reduce downtime.

As the industry continues to innovate, we can anticipate a future where desalination plays a vital role in ensuring global water security, supporting economic development, and protecting the environment.

Case Studies of Successful Desalination Plants

Examining case studies of operational desalination plants reveals key factors in their success. These examples not only demonstrate the effectiveness of desalination technology but also provide valuable insights into the challenges faced and overcome by these projects.

Notable Example: Carlsbad Desalination Plant

The Carlsbad Desalination Plant in California is a notable example of a successful desalination project. Opened in 2015, it was the largest seawater desalination plant in the United States at the time, producing 50 million gallons of drinking water per day. This project showcases the potential of desalination to contribute significantly to a region’s water supply.

The success of the Carlsbad Desalination Plant can be attributed to its advanced technology and careful planning. The plant utilizes reverse osmosis technology, which is a key factor in its efficiency and effectiveness. Additionally, the project’s environmental considerations, such as the intake system’s design to minimize harm to marine life, have been noteworthy.

Lessons Learned from International Projects

International desalination projects offer a wealth of knowledge on overcoming the challenges associated with desalination. For instance, projects in the Middle East have developed innovative solutions to deal with high-salinity waters and extreme temperatures. These projects demonstrate the importance of adapting technology to local conditions.

One of the key lessons from international projects is the need for comprehensive planning and community engagement. Successful projects often involve extensive environmental impact assessments and public outreach programs. This not only helps in addressing public concerns but also in ensuring the project’s compliance with regulatory standards.

Furthermore, international projects highlight the importance of energy efficiency and the integration of renewable energy sources. As the world moves towards more sustainable practices, desalination plants are incorporating solar and other renewable energy sources to reduce their carbon footprint.

Conclusion: Bridging the Water Scarcity Gap

As the global demand for clean water continues to rise, desalination emerges as a vital solution to address water scarcity. The design and operation of desalination plants involve complex engineering processes that require careful consideration of various factors, including technology selection, environmental impact, and energy efficiency.

Key Takeaways from Desalination Plant Design

Effective desalination plant design hinges on understanding the different types of desalination processes, such as reverse osmosis and multi-stage flash distillation. Site selection, pre-treatment systems, and energy consumption are also crucial elements that influence the overall efficiency and sustainability of the plant.

Collaborative Efforts for a Water-Secure Future

To bridge the water scarcity gap, stakeholders must work together to develop sustainable and efficient desalination projects. This involves not only leveraging advances in desalination technology but also fostering collaboration among governments, private investors, and local communities to ensure the long-term viability of these projects. By doing so, we can effectively address the pressing issue of water scarcity and create a more water-secure future.

By summarizing the key takeaways and issuing a call to action, we can move towards a more sustainable solution for water scarcity, ultimately reaching a successful conclusion in our efforts to provide clean water for all.