Are you aware of the critical factors that can make or break a glazing project? A successful glazing system installation requires precision, expertise, and a thorough understanding of the key components involved.

At Tough Glass, experts emphasize the importance of being educated and certified in glazing system installation best practices. This article will provide expert tips for a successful installation, covering site preparation, measuring techniques, and common installation issues.

Key Takeaways

- Understanding the importance of precision in glazing system installation

- Key components involved in a successful glazing project

- Expert tips for site preparation and measuring techniques

- Common installation issues and how to avoid them

- The significance of being educated and certified in glazing system installation

Understanding Glazing Systems

Glazing systems play a pivotal role in modern construction, combining style with functional benefits. According to Roble Glass & Railings, glass plays a crucial role in adding elegance and functionality to various spaces, emphasizing the importance of proper glass installation to avoid common pitfalls.

What is a Glazing System?

A glazing system refers to the assembly of components that work together to provide a transparent or translucent barrier, typically made of glass, in buildings. These systems are designed to provide natural light, insulation, and weather resistance while enhancing the aesthetic appeal of a structure.

“The right glazing solution can significantly impact the overall energy efficiency and ambiance of a building,” says experts in the field of glass installation techniques.

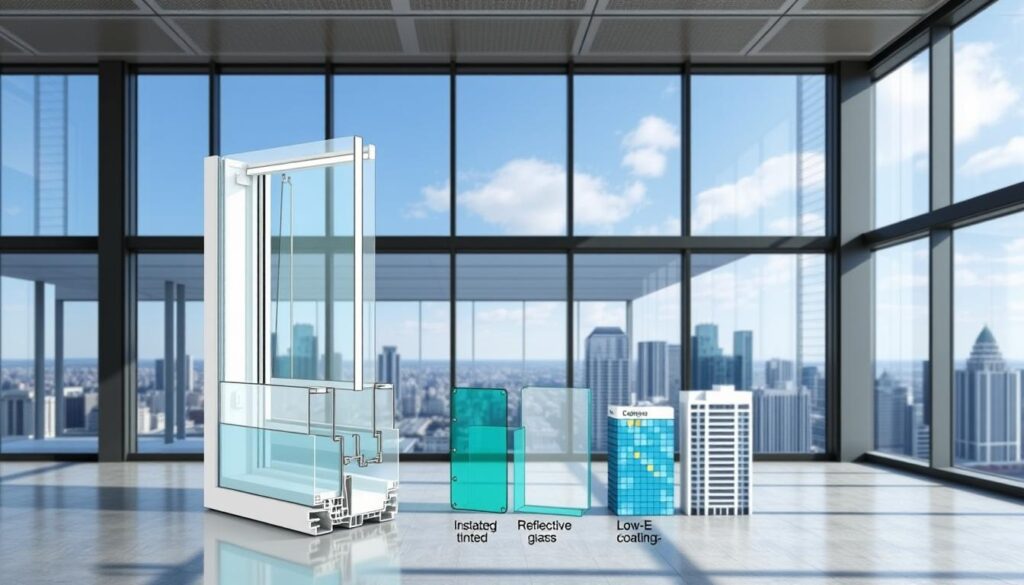

Types of Glazing Systems

There are various types of glazing systems, including:

- Single glazing: Uses a single pane of glass.

- Double glazing: Employs two panes of glass with a gap in between for improved insulation.

- Triple glazing: Utilizes three panes of glass for enhanced thermal performance.

- Structural glazing: Involves the use of glass as a structural element.

Each type has its advantages and is suited to different applications, from residential windows to commercial facades.

Benefits of Effective Glazing

Effective glazing solutions offer numerous benefits, including:

- Improved energy efficiency through reduced heat transfer.

- Enhanced natural lighting, reducing the need for artificial lighting.

- Increased security and safety through the use of laminated or tempered glass.

- Aesthetic appeal, with a wide range of glass types and framing options available.

By choosing the right glazing system, builders and architects can create spaces that are not only visually appealing but also functional and sustainable.

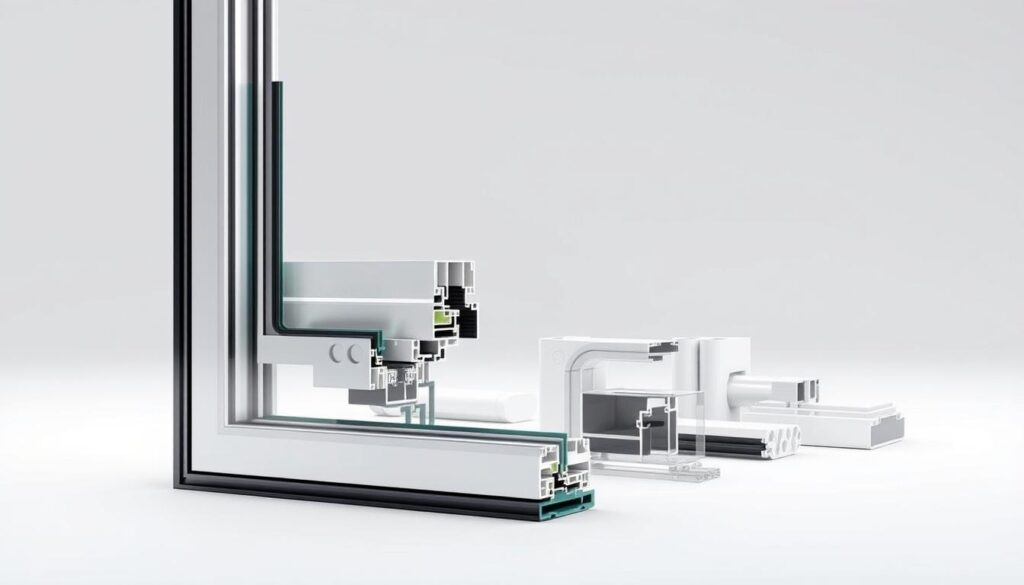

Key Components of Glazing Systems

To ensure a glazing system functions optimally, it’s essential to understand its core components. The effectiveness of a glazing system depends on the quality and compatibility of its key elements.

Frame Materials

The frame is the backbone of any glazing system, providing structural support and determining the system’s overall durability and aesthetic appeal. Common frame materials include aluminum, vinyl, wood, and fiberglass, each with its unique benefits and drawbacks.

Aluminum frames are popular in commercial glazing due to their strength, durability, and resistance to corrosion. They can be anodized or powder-coated to enhance their appearance and performance.

Vinyl frames offer excellent thermal insulation and are often used in residential window installation guidelines. They are low maintenance and can be more cost-effective than other materials.

Glazing Inserts

Glazing inserts, typically made of glass or plastic, are the transparent or translucent components that provide daylight and visibility. The choice of glazing insert depends on factors such as energy efficiency, noise reduction, and safety requirements.

- Single glazing is the most basic form, suitable for certain non-residential applications.

- Double or triple glazing offers improved thermal insulation and is commonly used in both residential and commercial glazing projects.

Sealants and Gaskets

Sealants and gaskets play a critical role in ensuring the glazing system’s weatherproofing and structural integrity. They prevent water infiltration and air leakage, reducing the risk of damage and energy loss.

Silicone sealants are widely used due to their flexibility, durability, and resistance to weathering. They are suitable for a variety of applications, including curtain wall installations.

When selecting sealants and gaskets, it’s crucial to consider factors such as compatibility with other materials, exposure to weather conditions, and the specific requirements of the glazing system.

By understanding and selecting the right key components for a glazing system, professionals can ensure a successful installation that meets both functional and aesthetic requirements, following best practices for window installation guidelines and commercial glazing tips.

Site Preparation for Installation

The foundation of a successful glazing installation lies in thorough site preparation. This critical phase ensures that the installation process is smooth, efficient, and safe.

Assessing the Installation Area

Before commencing the installation, it’s crucial to assess the installation area thoroughly. This involves checking for any debris, obstructions, or structural issues that could impede the installation process. A thorough assessment helps in identifying potential challenges early on, allowing for timely adjustments to be made.

Key factors to consider during the assessment include:

- The condition and integrity of the surrounding structure

- Availability of necessary utilities and services

- Accessibility to the installation site

Gathering Tools and Materials

Gathering all necessary tools and materials before starting the installation is a best practice that enhances efficiency and reduces downtime. This includes ensuring that all components of the glazing system are on site and that the necessary installation tools are available and in good condition.

For more detailed information on best practices for glazing installation, you can refer to resources such as best practices for applying commercial IGU.

Ensuring a Safe Work Environment

Ensuring a safe work environment is paramount during the installation of glazing systems. This involves implementing safety protocols such as wearing protective gear, securing the workspace, and training personnel on safety procedures. Companies like Roble Glass & Railings emphasize the importance of safety protocols during glass installation.

Safety measures to implement include:

- Wearing personal protective equipment (PPE)

- Securing the workspace to prevent unauthorized access

- Regularly inspecting equipment and tools

By following these steps and adhering to industrial glass best practices, installers can ensure a successful and safe glazing installation process.

Best Practices for Measuring

Accurate measurements are the cornerstone of a successful glazing system installation. According to Roble Glass & Railings, incorrect measurements are a common mistake in glass installation, emphasizing the need for precision. Ensuring that measurements are accurate is crucial for avoiding costly rework and ensuring the structural integrity of the glazing system.

Importance of Accurate Measurements

Accurate measurements are vital for the proper fitting of glazing systems. Inaccurate measurements can lead to significant issues, including compromised structural integrity and increased installation costs. The importance of precision cannot be overstated, as it directly affects the overall quality and performance of the glazing system. As industry experts emphasize, “Precision in measurement is key to a successful glazing installation.”

“Precision in measurement is key to a successful glazing installation.” – Industry Expert

Techniques for Measuring Glass Panels

To achieve accurate measurements, professionals employ various techniques. Using calibrated measuring tools and verifying measurements multiple times are essential practices. Additionally, considering the architectural glazing standards and professional glass fitting methods is crucial for ensuring compliance and quality.

- Use of digital measuring devices for precision

- Double-checking measurements to avoid errors

- Accounting for any irregularities in the installation area

Common Measurement Pitfalls to Avoid

Avoiding common pitfalls is as important as employing the right measuring techniques. Failing to account for the expansion and contraction of materials due to temperature changes can lead to measurement errors. Being aware of these potential issues can help professionals take necessary precautions.

Some common pitfalls include:

- Not considering the glazing system’s frame material and its properties

- Ignoring the impact of environmental factors on measurements

- Using inappropriate measuring tools for the task

By understanding the importance of accurate measurements, employing the right techniques, and avoiding common pitfalls, professionals can ensure a successful glazing system installation that meets architectural glazing standards and adheres to professional glass fitting methods.

Installation Techniques for Glazing Systems

Installing glazing systems demands a comprehensive understanding of the techniques and best practices involved. Effective glazing solutions not only enhance the aesthetic appeal of a building but also contribute to its energy efficiency and structural integrity.

Step-by-Step Installation Guide

A successful glazing system installation involves several key steps. First, it’s essential to prepare the site by ensuring it is clean and free from debris. Next, the frames are assembled and installed according to the manufacturer’s instructions. The glazing inserts are then carefully placed within the frames, followed by the application of sealants and gaskets to ensure a watertight seal.

For more detailed insights into glass installation techniques, you can refer to resources such as https://esnaglass.com/glass/glass-installation-techniques/, which provides comprehensive guidance on various installation methods.

Common Installation Methods

There are several common installation methods used for glazing systems, including stick-built, unitized, and semi-unitized systems. Each method has its advantages and is suited to different project requirements. For instance, unitized systems are often preferred for high-rise buildings due to their efficiency and quality control benefits.

Stick-built systems, on the other hand, offer flexibility and are typically used in lower-rise buildings or projects with complex geometries.

Tools for Efficient Installation

Efficient installation of glazing systems requires the right tools and equipment. This includes precision measuring tools, specialized glazing tools, and appropriate safety gear. Using the correct tools not only speeds up the installation process but also ensures that the glazing system is installed to the highest standards.

- Precision measuring tools for accurate measurements

- Specialized glazing tools for handling and placing glazing inserts

- Safety gear to protect workers during the installation process

Handling Glass Safely

Effective glass handling is crucial for successful glazing system installations. Roble Glass & Railings emphasizes the importance of safety protocols during glass handling and installation. This not only prevents injuries but also ensures that the glass is installed correctly, maintaining the integrity of the glazing system.

Safety Gear Required

When handling glass, it’s essential to wear the appropriate safety gear. This includes gloves to prevent cuts, safety glasses to protect the eyes from shards, and steel-toed boots to safeguard against heavy objects. For more information on safety practices, visit Glass Magazine’s article on glass handling.

Additionally, using protective clothing like long sleeves and pants can provide extra protection against cuts and abrasions. Ensuring that all safety gear is in good condition before starting work is crucial.

Safe Lifting Techniques

Lifting glass panels requires careful technique to avoid injury and damage. It’s recommended to use mechanical lifting aids whenever possible to reduce the risk of manual handling injuries. When manual lifting is necessary, using proper lifting techniques, such as bending at the knees and lifting with the legs, can help prevent strain.

For larger or heavier glass panels, having a team of people to assist with lifting can help distribute the weight more evenly and reduce the risk of accidents.

Transporting Glass Panels

Transporting glass panels from the storage area to the installation site requires careful planning. Using glass handling suction cups or A-frames can help secure the glass during transport, reducing the risk of breakage. It’s also important to ensure that the path is clear of obstacles and that the transport route is stable and even.

Following window installation guidelines and commercial glazing tips can further enhance safety and efficiency during the transportation and installation of glass panels. By prioritizing safety, glazing professionals can ensure a successful installation process.

Sealing and Waterproofing

Effective sealing and waterproofing are crucial for the longevity and performance of glazing systems. A well-sealed system prevents water infiltration, reduces air leakage, and maintains energy efficiency.

Importance of Proper Sealing

Proper sealing is essential to prevent damage from water ingress and to maintain the structural integrity of the building. According to Sika’s window installation solutions, weatherproofing is a critical aspect of curtain wall installations.

Sealing prevents:

- Water damage

- Air leakage

- Energy loss

- Reduced maintenance costs

Types of Sealants

There are various types of sealants used in glazing systems, each with its own advantages and applications.

| Type of Sealant | Characteristics | Applications |

|---|---|---|

| Silicone | Flexible, UV resistant | Exterior glazing, curtain walls |

| Polyurethane | High adhesion, durable | Structural glazing, heavy-duty applications |

| Acrylic | Easy to paint, flexible | Interior applications, general sealing |

Application Techniques

The application of sealants requires careful planning and execution. Best practices include ensuring clean surfaces, using the correct amount of sealant, and allowing adequate curing time.

By following these guidelines and using the appropriate sealants, builders can ensure a durable and energy-efficient glazing system.

Maintaining Structural Integrity

Maintaining structural integrity is crucial for the longevity and safety of glazing systems. According to Advantage Drafting, this aspect is particularly important in curtain wall installations, where any compromise can lead to significant issues.

Checking for Level and Plumb

Ensuring that the glazing system is properly aligned is fundamental. Checking for level and plumb involves verifying that the installation area is perfectly horizontal and vertical. This step is critical in adhering to architectural glazing standards.

Reinforcing Frames

The frames of glazing systems must be robust enough to support the weight and stress of the glass panels. Professional glass fitting methods dictate that frames should be reinforced, especially in large or complex installations.

Addressing Structural Issues

Any structural issues identified during the installation process must be addressed promptly. This includes correcting any misalignments or weaknesses in the frame. Utilizing professional glass fitting methods ensures that the glazing system performs optimally and safely.

| Structural Integrity Aspect | Description | Importance Level |

|---|---|---|

| Checking for Level and Plumb | Ensuring the installation area is perfectly horizontal and vertical. | High |

| Reinforcing Frames | Strengthening frames to support glass panels. | High |

| Addressing Structural Issues | Correcting misalignments or weaknesses in the frame. | Critical |

Troubleshooting Common Installation Issues

Even with the best glass installation techniques, issues can still occur, making troubleshooting an essential skill for ensuring the longevity and integrity of glazing solutions.

Installation problems can arise from various sources, including incorrect measurements, improper use of tools, and inadequate sealing. According to Roble Glass & Railings, common installation mistakes often stem from these areas, highlighting the need for vigilant troubleshooting practices.

Identifying Common Problems

One of the first steps in troubleshooting is identifying common problems that may occur during glazing installation. These can include:

- Misalignment of glass panels

- Inadequate sealing leading to water infiltration

- Incorrect frame assembly

Recognizing these issues early on can significantly reduce the complexity and cost of repairs.

Solutions for Misalignment

Misalignment is a common issue that can lead to both functional and aesthetic problems. To address misalignment:

- Check the frame for level and plumb, ensuring it is properly aligned before proceeding with glass installation.

- Use shims to adjust the position of the glass panels if necessary, ensuring they are correctly aligned within the frame.

- Verify that the glazing beads or retaining clips are securely in place, holding the glass firmly in its correct position.

Fixing Sealant Failures

Sealant failure can lead to water infiltration and reduced energy efficiency. To fix sealant failures:

- Inspect the sealant for signs of deterioration or damage, such as cracking or detachment.

- Clean the area thoroughly before applying new sealant, ensuring a strong bond.

- Apply the appropriate type of sealant for the specific application, following manufacturer instructions.

By addressing these common installation issues proactively, installers can ensure that glazing solutions perform optimally and last longer.

Compliance and Standards

Understanding and adhering to compliance and standards is vital in the glazing industry. Ensuring that glazing systems are installed according to relevant codes and standards is not only a legal requirement but also crucial for safety, durability, and performance.

Building Codes and Regulations

Building codes and regulations vary by jurisdiction but are essential for ensuring that glazing installations meet minimum safety standards. For instance, glazing guidelines standard outlines specific requirements that must be followed. Compliance with these regulations is critical to avoid legal issues and ensure the structural integrity of the building.

- Familiarize yourself with local building codes and regulations.

- Ensure all glazing installations meet or exceed these standards.

- Regularly update your knowledge as codes and regulations evolve.

Industry Standards for Glazing

Industry standards for glazing, such as those outlined by AS1288, provide detailed guidelines for the safe installation and performance of glazing systems. Adhering to these standards is crucial for ensuring the quality and safety of glazing installations.

Key industry standards include:

- Standards for glass thickness and type.

- Guidelines for frame materials and construction.

- Specifications for sealing and waterproofing.

Importance of Certification

Certification is a critical aspect of compliance in the glazing industry. It ensures that installers and products meet specific standards, thereby enhancing safety and performance. Certification bodies test products and installers against established standards, providing assurance that they meet required criteria.

The benefits of certification include:

- Enhanced credibility and trust among clients.

- Compliance with legal and regulatory requirements.

- Improved safety and performance of glazing systems.

By understanding and adhering to compliance and standards, professionals in the glazing industry can ensure that their installations are safe, durable, and meet the required regulations. This not only protects the installers and building occupants but also enhances the overall quality of the glazing system.

Preventative Maintenance after Installation

After installing a glazing system, it’s crucial to implement a preventative maintenance routine to ensure longevity and performance. Proper maintenance not only extends the life of the glazing system but also maintains its aesthetic appeal and functionality.

Regular Inspections

Regular inspections are vital to identify potential issues before they become major problems. It is recommended to inspect the glazing system at least twice a year, checking for signs of wear, damage, or deterioration. According to Roble Glass & Railings, proper maintenance is key to ensuring the longevity of glass installations.

During inspections, pay particular attention to the seals, frames, and glass panels. Look for any signs of leakage, rust, or cracks. Ensuring that all components are in good condition will help maintain the overall integrity of the glazing system.

Cleaning and Care Tips

Cleaning is an essential part of maintaining a glazing system. Use appropriate cleaning solutions and materials to avoid damaging the glass or frames. For instance, using a mild soap solution with a soft cloth is generally safe for most glazing systems.

Avoid using abrasive materials or harsh chemicals, as they can scratch or corrode the components. Regular cleaning not only keeps the glazing system looking its best but also helps in early detection of potential issues.

Recognizing Signs of Wear

Being able to recognize signs of wear and tear is crucial for maintaining the glazing system. Common signs include fogging between glass panels, rust on metal frames, or cracks in the glass. Addressing these issues promptly can prevent further damage.

For more detailed guidance on preventive maintenance, especially for high-rise windows, you can refer to resources like https://ntpropertycare.com/high-rise-windows-preventive-maintenance/, which provide comprehensive insights into maintaining complex glazing systems.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Inspect Seals and Frames | Twice a Year | High |

| Clean Glass Panels | Quarterly | Medium |

| Check for Damage | Monthly | High |

Cost Considerations for Glazing Systems

Effective budgeting for glazing systems requires a comprehensive understanding of both initial and long-term costs. When planning a glazing project, it’s essential to consider various factors that influence the overall expense, from material selection to installation techniques.

Budgeting for Installation

Budgeting for the installation of a glazing system involves several key considerations. First, the cost of materials, including the type of glass, frame materials, and sealants, must be assessed. High-quality materials may have a higher upfront cost but can provide long-term savings through reduced maintenance and energy efficiency.

Here are some factors to consider when budgeting for installation:

- The complexity of the glazing design

- The size and number of glass panels

- Labor costs and the expertise of the installers

- Any necessary structural modifications to accommodate the glazing system

Cost-Saving Tips

To save on costs without compromising on quality, consider the following strategies:

- Opt for energy-efficient glazing solutions that can reduce heating and cooling costs over time.

- Select materials that are durable and require minimal maintenance.

- Plan the installation during off-peak seasons when contractors may offer discounts.

Additionally, adhering to architectural glazing standards and employing professional glass fitting methods can prevent costly errors and ensure a successful installation.

Long-Term Investment Benefits

Investing in a high-quality glazing system can yield significant long-term benefits, including enhanced energy efficiency, improved building aesthetics, and increased property value. While the initial investment may be substantial, the long-term savings and benefits can far outweigh the costs.

Some of the long-term benefits include:

- Reduced energy consumption through advanced glazing technologies

- Lower maintenance costs due to durable materials and construction

- Potential increases in property value due to the enhanced appearance and functionality of the glazing system

Working with Professionals

Professional glazing installers bring a level of quality and precision that is hard to match with DIY approaches. Their expertise ensures that glazing systems are installed correctly, enhancing both the functionality and aesthetic appeal of the installation.

When to Hire an Expert

Hiring a professional for glazing installation is particularly important for complex projects or when working with large glass panels. Experts have the necessary training and equipment to handle these installations safely and efficiently.

Moreover, professionals can provide valuable insights into the best glazing solutions for specific needs, taking into account factors like energy efficiency, durability, and design preferences.

Finding Qualified Installers

To find a qualified glazing installer, it’s essential to do thorough research. This includes checking for certifications, reading reviews, and asking for references. Companies like Roble Glass & Railings emphasize the importance of hiring professionals with a proven track record in glass installation techniques.

A qualified installer will not only ensure a high-quality installation but also provide guidance on maintenance and care to extend the lifespan of the glazing system.

Questions to Ask Contractors

When engaging with potential contractors, it’s crucial to ask the right questions. These should include inquiries about their experience with similar projects, the materials they use, and their approach to ensuring the structural integrity of the glazing system.

Additionally, discussing warranty options, timelines, and costs upfront can help prevent misunderstandings and ensure a smooth installation process.

| Aspect to Consider | Questions to Ask | Importance Level |

|---|---|---|

| Experience | How many similar projects have you completed? | High |

| Materials | What type of glass and framing materials do you use? | Medium |

| Warranty | What kind of warranty do you offer on your work? | High |

| Timeline | What is the expected completion date for the project? | Medium |

| Cost | What is the total cost of the project, including materials and labor? | High |

Future Trends in Glazing Technology

The glazing industry is on the cusp of a revolution, driven by innovations in materials and technologies. According to Advantage Drafting, there are ongoing advancements in glazing materials and technologies that are transforming the industry.

Advancements in Materials

New glazing materials are being developed to provide improved thermal performance, durability, and sustainability. These advancements are crucial for meeting the demands of modern construction projects, where energy efficiency and environmental considerations are paramount. Following window installation guidelines can help ensure that these new materials are installed correctly.

Smart Glazing Solutions

Smart glazing solutions are becoming increasingly popular, offering enhanced functionality and energy efficiency. These solutions can be integrated into commercial glazing projects, providing building owners with improved control over lighting and temperature. By incorporating commercial glazing tips into the design process, architects and builders can create more sustainable and efficient buildings.

Eco-Friendly Practices

Sustainability is a growing concern in the glazing industry, with a focus on eco-friendly practices and materials. As the industry continues to evolve, we can expect to see more emphasis on sustainable glazing solutions that minimize environmental impact while maintaining performance and aesthetic appeal.