Mechatronics integrates mechanical and electrical systems to create innovative solutions. This interdisciplinary field combines the principles of mechanical and electrical engineering design to develop intelligent products.

By merging mechanics and electronics, mechatronics engineers create complex systems that are more efficient and reliable. This fusion of technologies has led to significant advancements in various industries.

Key Takeaways

- Mechatronics combines mechanical and electrical systems.

- It is an interdisciplinary field that requires a broad skill set.

- Mechatronics engineers design and develop innovative products.

- The field has numerous applications across various industries.

- Mechatronics engineering is crucial for creating intelligent systems.

What is Mechatronics Engineering?

Mechatronics engineering represents a synergistic fusion of mechanical engineering, electronics, and computer science. This multidisciplinary field focuses on designing and developing intelligent systems that integrate mechanical, electrical, and software components.

Definition and Core Concepts

Mechatronics engineering is defined as the integration of mechanics, electronics, and computing to create sophisticated systems that can perform complex tasks. The core concepts include understanding control systems, mechanical systems, and electronic systems. Mechatronic engineers design and develop products that range from simple household appliances to complex industrial automation systems.

| Component | Description | Examples |

|---|---|---|

| Mechanical Systems | Physical structures and mechanisms | Gears, motors, linkages |

| Electronic Systems | Circuits and electronic components | Microcontrollers, sensors, actuators |

| Control Systems | Systems that control and regulate behavior | Feedback control, PID controllers |

The Interdisciplinary Nature of Mechatronics

The interdisciplinary nature of mechatronics engineering allows it to tackle complex problems by combining insights from multiple fields. Mechatronic systems are designed to be intelligent, flexible, and adaptable, often incorporating elements of robotics and automation. By merging mechanics, electronics, and computing, mechatronics engineers can create innovative solutions that transform industries.

The Evolution of Mechatronics Engineering

The evolution of mechatronics engineering is a story of continuous innovation, from its early beginnings to the current state-of-the-art technologies. This multidisciplinary field has grown significantly, influenced by advancements in mechanics, electronics, and computing.

Historical Development

Mechatronics engineering has its roots in the early 20th century when the first automated systems were introduced. The term “mechatronics” was coined in the 1960s by a Japanese engineer, Tetsuro Mori, who worked at Yaskawa Electric Corporation. Initially, it referred to the integration of mechanical and electrical systems. Over time, the field expanded to include aspects of computing and software engineering, leading to the sophisticated mechatronic systems we see today.

The historical development of mechatronics is closely tied to advancements in industrial automation and robotics technology. As manufacturing processes became more complex, the need for integrated systems that could perform multiple tasks efficiently grew. This led to the development of more sophisticated mechatronic systems capable of precision and flexibility.

Key Milestones in the Field

Several key milestones have marked the evolution of mechatronics engineering. The introduction of microprocessors in the 1970s revolutionized the field by enabling more complex control systems. The 1980s saw the advent of robotics in manufacturing, further accelerating the development of mechatronics. In recent years, advancements in artificial intelligence and the Internet of Things (IoT) have opened new avenues for mechatronics innovations.

Today, mechatronics engineering continues to play a crucial role in shaping various industries, from automotive and aerospace to healthcare and consumer electronics. The field is expected to evolve further with ongoing research and technological advancements, leading to even more integrated and intelligent systems.

Core Components of Mechatronics Systems

At the heart of mechatronics engineering are four primary systems that enable its functionality: mechanical systems, electronic systems, control systems, and computer systems. These components work together seamlessly to create sophisticated mechatronic systems.

Mechanical Systems

Mechanical systems form the backbone of mechatronics, providing the physical structure and motion required for various applications. They include actuators, motion control mechanisms, and carefully designed structural elements.

Actuators and Motion Control

Actuators are crucial for converting energy into motion. They are used in various mechatronic systems, from simple robotic arms to complex manufacturing machinery. Motion control involves regulating the movement of these actuators to achieve precise operations.

Structural Design Considerations

The structural design of mechanical systems is vital for ensuring durability and performance. Factors such as material selection, stress analysis, and thermal management are considered to optimize the system’s overall efficiency.

Electronic Systems

Electronic systems are integral to mechatronics, providing the necessary control and power management. They encompass circuit design, power electronics, and signal processing.

Circuit Design and Power Management

Circuit design involves creating electronic circuits that can efficiently manage power and control signals. Power management is critical for ensuring that mechatronic systems operate reliably and efficiently.

Signal Processing

Signal processing is essential for interpreting and manipulating signals within mechatronic systems. It enables the systems to respond appropriately to various inputs and conditions.

Control Systems

Control systems play a pivotal role in mechatronics by regulating the behavior of mechanical and electronic components. They use feedback loops to maintain desired performance and stability.

- Feedback control mechanisms

- Stability analysis

- Controller design

Computer Systems and Programming

Computer systems and programming are vital for the operation and control of mechatronic systems. They enable the implementation of complex algorithms and data processing.

- Software development for mechatronics

- Microcontroller programming

- Data acquisition and processing

Fundamental Technologies in Mechatronics

The backbone of mechatronics lies in its fundamental technologies, which enable the creation of sophisticated automated systems. Mechatronics engineering combines various disciplines to develop innovative products and systems.

Sensors and Actuators

Sensors and actuators are crucial components in mechatronic systems. Sensors detect changes in the environment, such as temperature, pressure, or light, and convert these changes into electrical signals. Actuators, on the other hand, execute actions based on these signals, enabling the system to interact with its environment. Together, they form a feedback loop that is essential for system control and automation.

The advancement in sensor technology has led to more precise and reliable data acquisition, which is vital for the performance of mechatronic systems. For instance, in robotics, sensors enable the robot to perceive its environment, while actuators allow it to perform tasks.

Microcontrollers and Embedded Systems

Microcontrollers and embedded systems are the brain behind mechatronic systems, providing the necessary computational power to process data and execute commands. Microcontrollers integrate a processor, memory, and input/output peripherals on a single chip, making them ideal for controlling mechatronic systems.

Embedded systems, which include microcontrollers, are designed to perform specific tasks within a larger system. They are optimized for low power consumption and high reliability, making them suitable for a wide range of applications, from consumer electronics to industrial automation.

Signal Processing and Data Acquisition

Signal processing and data acquisition are critical in mechatronics for interpreting sensor data and making informed decisions. Signal processing involves filtering, amplifying, and converting signals to extract meaningful information. Data acquisition systems capture and process data from sensors, enabling real-time monitoring and control.

Effective signal processing and data acquisition are essential for the optimal performance of mechatronic systems. They enable precise control, improve system reliability, and facilitate the development of more sophisticated automated systems.

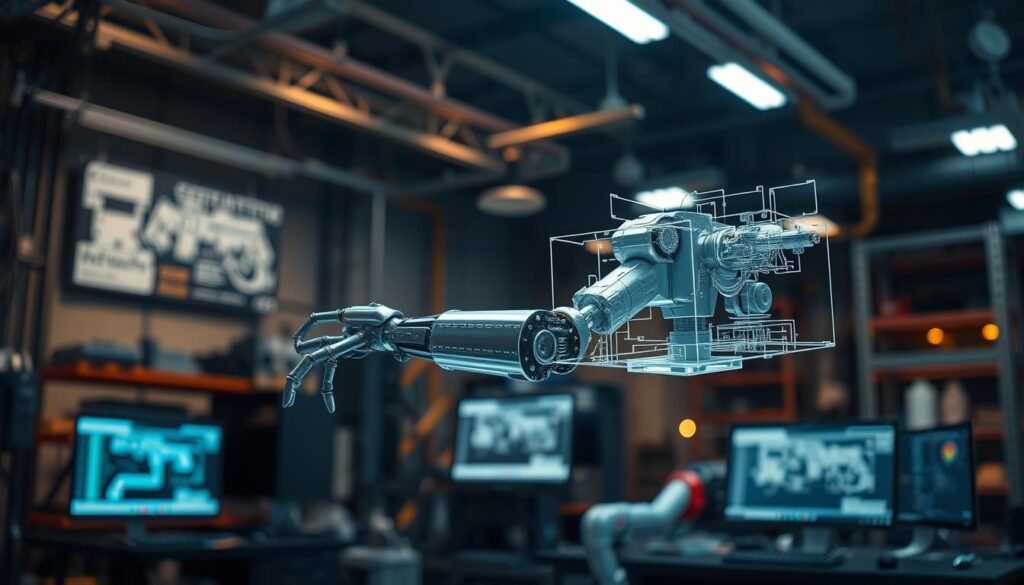

Applications of Mechatronics Engineering

Mechatronics engineering is revolutionizing industries through its innovative applications. The integration of mechanical, electronic, and software components has led to the development of intelligent systems that are transforming various sectors.

Industrial Automation and Robotics

Mechatronics plays a crucial role in industrial automation and robotics. Automated manufacturing systems and robotic arms are used in production lines to improve efficiency and precision. These systems are equipped with sensors and actuators that enable them to perform complex tasks.

- Improved productivity

- Enhanced precision

- Reduced labor costs

Consumer Electronics and Smart Devices

The consumer electronics industry has seen significant advancements due to mechatronics. Smart devices such as smartphones, smart home appliances, and wearable technology rely on mechatronic systems to provide advanced functionality and user interfaces.

“The integration of mechatronics in consumer electronics has led to the development of more intuitive and interactive products.” – Industry Expert

Automotive Mechatronics

Automotive mechatronics has become increasingly important in modern vehicles. Systems such as anti-lock braking (ABS), traction control, and electronic stability control are all mechatronic applications that enhance vehicle safety and performance.

- Improved safety features

- Enhanced vehicle performance

- Increased driver comfort

Medical and Biomedical Applications

Mechatronics has made significant contributions to medical and biomedical applications. Medical devices such as robotic surgical systems, prosthetic limbs, and diagnostic equipment rely on mechatronic systems to provide precise and reliable performance.

The use of mechatronics in medical applications has led to improved patient outcomes and enhanced healthcare services.

Robotics: The Pinnacle of Mechatronics

Robotics represents the culmination of mechatronics engineering, integrating mechanical, electronic, and computational systems. This field has seen significant advancements, leading to the development of various robotic systems that are transforming industries and daily life.

Types of Robotic Systems

Robotic systems can be categorized into several types based on their application and functionality. These include:

- Industrial Robots

- Service and Collaborative Robots

- Autonomous Systems

Industrial Robots

Industrial robots are widely used in manufacturing for tasks such as assembly, welding, and material handling. They are known for their precision and efficiency, significantly improving production processes.

Service and Collaborative Robots

Service robots are designed to assist humans in various settings, including healthcare and domestic environments. Collaborative robots, or cobots, work alongside human workers, enhancing productivity and safety.

Autonomous Systems

Autonomous systems operate independently, making decisions based on their programming and sensor data. They are used in applications such as self-driving vehicles and drones.

Challenges in Robotics Design

Despite the advancements in robotics, several challenges remain in the design and development of robotic systems. These challenges include:

- Ensuring reliability and robustness

- Improving human-robot interaction

- Addressing ethical and safety concerns

Designing robotic systems that are both efficient and safe requires careful consideration of these challenges. By overcoming these hurdles, robotics can continue to evolve and benefit society.

Industry4.0 and Mechatronics Integration

As Industry4.0 continues to evolve, its integration with Mechatronics Engineering is becoming increasingly vital for modern manufacturing. The fusion of these technologies is driving significant advancements in production processes, making them more efficient, flexible, and responsive to changing demands.

Smart Manufacturing Systems

Smart manufacturing systems represent a key aspect of Industry4.0, leveraging advanced technologies such as Artificial Intelligence (AI) and Internet of Things (IoT) to optimize production. These systems enable real-time monitoring, predictive maintenance, and adaptive control, leading to improved product quality and reduced operational costs.

Industrial IoT and Digital Twins

The Industrial IoT (IIoT) is a critical component of Industry4.0, connecting machines, sensors, and devices to facilitate data exchange and analysis. Digital Twins, virtual replicas of physical assets, play a crucial role in IIoT by enabling simulation, prediction, and optimization of complex systems. This integration enhances decision-making and operational efficiency.

| Technology | Description | Benefits |

|---|---|---|

| Industrial IoT | Network of connected devices and sensors | Real-time monitoring, predictive maintenance |

| Digital Twins | Virtual replicas of physical assets | Simulation, prediction, optimization |

| Cyber-Physical Systems | Integration of physical and computational systems | Enhanced control, adaptability, and efficiency |

Cyber-Physical Systems

Cyber-physical systems (CPS) are engineered systems that integrate physical and computational components, enabling advanced control and adaptability. In the context of Industry4.0, CPS facilitate the interaction between the physical and digital worlds, driving innovations in manufacturing and beyond.

The integration of Mechatronics Engineering with Industry4.0 technologies like smart manufacturing, IIoT, digital twins, and CPS is transforming the manufacturing landscape. As these technologies continue to evolve, we can expect even more sophisticated and efficient production systems.

Artificial Intelligence in Mechatronics

The integration of Artificial Intelligence (AI) in Mechatronics is revolutionizing the field by enhancing system efficiency and autonomy. AI technologies are being increasingly adopted to improve the performance, adaptability, and decision-making capabilities of mechatronic systems.

Machine Learning Applications

Machine learning is a subset of AI that is being utilized in Mechatronics to enable systems to learn from data and improve their operations over time. This involves various applications, including:

Predictive Maintenance

Predictive maintenance uses machine learning algorithms to predict when maintenance should be performed, reducing downtime and increasing overall system reliability.

Adaptive Control Systems

Adaptive control systems adjust their parameters in real-time to optimize performance, even in changing conditions, thanks to machine learning.

Optimization Algorithms

Machine learning-based optimization algorithms are used to find the most efficient solutions for complex problems in mechatronic systems.

Computer Vision and Intelligent Systems

Computer vision, another critical aspect of AI, is being integrated into mechatronic systems to enable them to interpret and understand visual data from the environment. This is particularly useful in applications such as robotics, where intelligent systems can perform tasks that require visual perception and decision-making.

The combination of AI and Mechatronics is leading to the development of more sophisticated and capable systems. As AI technologies continue to evolve, we can expect to see even more innovative applications in the field of Mechatronics.

Education Pathways for Mechatronics Engineers

Educational pathways for Mechatronics Engineers are diverse, encompassing various academic programs and technical skills. As the field continues to evolve, it’s crucial for aspiring engineers to have a comprehensive education that prepares them for the interdisciplinary demands of mechatronics.

Academic Programs and Degrees

Mechatronics Engineering programs are offered at various academic levels, including undergraduate and graduate degrees. These programs typically combine coursework in mechanical engineering, electrical engineering, computer science, and control systems. Some institutions also offer specialized courses in robotics, automation, and mechatronics systems design.

A survey of top engineering schools reveals that many offer Bachelor’s and Master’s degrees in Mechatronics or related fields. For instance, the University of Michigan and the University of California, Berkeley, have well-regarded Mechatronics programs that include hands-on training and project-based learning.

| Degree Level | Typical Curriculum | Institutions |

|---|---|---|

| Bachelor’s | Mechanics, Electronics, Programming, Control Systems | University of Michigan, University of California, Berkeley |

| Master’s | Advanced Mechatronics, Robotics, Automation, Systems Design | Stanford University, MIT |

Essential Technical Skills

Mechatronics Engineers require a broad range of technical skills, including proficiency in programming languages such as C++, Python, and MATLAB. They must also be familiar with computer-aided design (CAD) software, microcontrollers, and sensor technologies.

“The integration of mechanical, electrical, and software engineering is what makes Mechatronics so unique and challenging. Engineers in this field must be adept at working with a variety of technologies and systems.” – Dr. John Smith, Mechatronics Professor

Other essential skills include data analysis, problem-solving, and collaboration. Mechatronics Engineers often work in teams, so the ability to communicate effectively and manage projects is crucial.

- Programming languages: C++, Python, MATLAB

- CAD software: SolidWorks, Autodesk Inventor

- Microcontrollers and sensors

- Data analysis and problem-solving

Hands-on Learning and Projects

Hands-on learning is a critical component of Mechatronics education. Students benefit from working on real-world projects that involve designing, building, and testing mechatronic systems. This practical experience helps to reinforce theoretical knowledge and develop problem-solving skills.

Many academic programs incorporate project-based learning, internships, or co-op programs to provide students with industry experience. For example, some universities partner with companies to offer students the opportunity to work on actual projects, applying their skills in a professional setting.

Career Opportunities in Mechatronics Engineering

Career opportunities in mechatronics engineering are diverse and continue to grow. As technology advances, the demand for professionals who can integrate mechanical, electrical, and software engineering is on the rise.

Job Roles and Responsibilities

Mechatronics engineers can take on various roles, including design engineer, control systems engineer, robotics engineer, and automation engineer. Their responsibilities often involve designing, developing, and maintaining complex systems that combine mechanical and electronic components.

Key Responsibilities:

- Designing and testing mechatronic systems

- Developing control algorithms and software

- Integrating mechanical and electronic components

- Troubleshooting and maintaining systems

Industry Sectors and Employers

Mechatronics engineers are sought after by various industries, including automotive, aerospace, healthcare, and consumer electronics. Top employers often include leading technology companies, research institutions, and manufacturing firms.

Notable Employers:

- Automotive manufacturers like Tesla and General Motors

- Aerospace companies such as Boeing and Lockheed Martin

- Healthcare technology firms like Medtronic

Salary Expectations and Growth Potential

The salary for mechatronics engineers can vary based on factors like location, industry, and experience. However, the field is known for offering competitive salaries and strong growth potential.

Average Salary Ranges:

| Experience Level | Average Salary |

|---|---|

| Entry-Level | $65,000 – $80,000 |

| Mid-Level | $90,000 – $120,000 |

| Senior-Level | $140,000 – $170,000 |

As technology continues to evolve, the demand for skilled mechatronics engineers is expected to grow, offering a promising career path for those in the field.

Tools and Software in Mechatronics Design

Effective mechatronics design requires a range of specialized software and tools. Mechatronics engineers rely on these tools to create, simulate, and optimize complex systems that integrate mechanical, electrical, and software components.

CAD/CAM Systems

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems are fundamental in mechatronics engineering. CAD software, such as SolidWorks and Autodesk Inventor, allows engineers to create detailed 3D models of their designs. CAM software, on the other hand, uses these models to generate manufacturing instructions for machines like CNC mills and lathes. The integration of CAD and CAM streamlines the design-to-manufacturing process, reducing production time and improving accuracy.

Simulation and Modeling Tools

Simulation and modeling tools are crucial for testing and validating mechatronics designs before physical prototypes are built. Software like MATLAB/Simulink and ANSYS enables engineers to simulate the behavior of complex systems under various conditions. These tools help identify potential issues early in the design process, saving time and resources. For instance, simulation can be used to optimize the control algorithms for a robotic arm or to analyze the thermal performance of an electronic system.

“Simulation is a powerful tool that allows engineers to explore the behavior of complex systems in a controlled environment, reducing the need for physical prototypes and accelerating the development process.” – Expert in Mechatronics Engineering

Programming Languages and Environments

Mechatronics engineers use a variety of programming languages and environments to develop software for their designs. Languages such as C++, Python, and MATLAB are commonly used, along with development environments like Arduino and Raspberry Pi. These tools enable engineers to create sophisticated control systems, interface with sensors and actuators, and implement advanced algorithms for tasks like machine learning and computer vision.

| Tool/Software | Application |

|---|---|

| SolidWorks | CAD design |

| MATLAB/Simulink | Simulation and modeling |

| Arduino | Prototyping and development |

In conclusion, the design of mechatronics systems relies on a diverse set of tools and software. From CAD/CAM systems to simulation and modeling tools, and programming languages, each plays a critical role in the development process. By leveraging these tools effectively, mechatronics engineers can create innovative solutions that integrate mechanical, electrical, and software components seamlessly.

Current Challenges in the Field of Mechatronics

Mechatronics engineering, a field that combines mechanics and electronics, faces numerous challenges in its pursuit of innovation. As the field continues to evolve, it encounters various technical, integration, and ethical hurdles.

Technical Limitations

One of the primary challenges in mechatronics is overcoming technical limitations. These include the development of more efficient actuators, improving sensor accuracy, and enhancing the processing power of microcontrollers. For instance, advancements in MEMS (Micro-Electro-Mechanical Systems) technology have been crucial in addressing some of these technical limitations.

| Technical Challenge | Description | Potential Solution |

|---|---|---|

| Actuator Efficiency | Limited efficiency in converting energy into motion | Advanced materials and designs |

| Sensor Accuracy | Inaccuracy in sensor readings due to noise or calibration issues | Improved calibration techniques and noise reduction algorithms |

Integration Complexities

Mechatronics systems integrate mechanical, electrical, and software components, which can lead to complexities in design and implementation. Ensuring seamless interaction between these components is a significant challenge. Effective integration requires a deep understanding of each component’s functionality and how they interact within the system.

Ethical and Social Considerations

Mechatronics engineering also raises ethical and social considerations. For example, the development of autonomous systems and robotics raises questions about job displacement and safety. It is essential to consider these factors when designing and implementing mechatronics systems to ensure they are socially responsible and ethically sound.

Future Trends in Mechatronics Engineering

Mechatronics engineering is on the cusp of a revolution, driven by emerging trends and technologies. The integration of advanced computational methods, artificial intelligence, and the Internet of Things (IoT) is transforming the field.

Emerging Technologies

Several emerging technologies are poised to significantly impact mechatronics engineering. Artificial intelligence (AI) and machine learning (ML) are being integrated into mechatronic systems to enhance their autonomy and decision-making capabilities. The use of advanced sensors and IoT devices is also becoming more prevalent, allowing for real-time data collection and analysis.

The development of cyber-physical systems is another key trend, where physical and computational components are deeply intertwined. This integration enables more efficient and adaptive systems.

Research Directions and Innovations

Research in mechatronics is focusing on several key areas, including the development of more sophisticated robotic systems and autonomous vehicles. Innovations in energy harvesting and power management are also crucial, enabling more sustainable and efficient mechatronic systems.

Furthermore, advancements in materials science and nanotechnology are opening new avenues for mechatronics engineering, allowing for the creation of smaller, more efficient, and more capable systems.

Real-World Mechatronics Projects and Case Studies

Real-world mechatronics projects are a testament to the field’s ability to innovate and solve complex problems. These projects span various industries, from industrial automation to consumer electronics, and demonstrate the versatility of mechatronics engineering.

Innovative Applications

Mechatronics has led to the development of numerous innovative applications. For instance, in the automotive industry, mechatronics is used in the development of advanced driver-assistance systems (ADAS) and autonomous vehicles. These systems integrate mechanical, electrical, and software components to enhance vehicle safety and performance.

In consumer electronics, mechatronics is pivotal in the design of smart devices, such as smartphones and smart home appliances. These devices rely on mechatronic systems to integrate sensors, actuators, and control systems, providing users with sophisticated functionalities.

Lessons from Successful Implementations

Successful mechatronics projects offer valuable lessons for engineers and researchers. One key takeaway is the importance of interdisciplinary collaboration. Mechatronics projects often involve teams with diverse expertise, including mechanical engineers, electrical engineers, and software developers. This collaboration is crucial for developing integrated systems that meet complex performance criteria.

Another lesson is the need for robust testing and validation. Mechatronics systems, which combine hardware and software components, require comprehensive testing to ensure reliability and performance. This involves both simulation-based testing and physical prototyping.

Student and Professional Projects

Both students and professionals are involved in mechatronics projects, each contributing unique perspectives. Student projects, often conducted as part of academic programs, focus on applying theoretical knowledge to practical problems. These projects help students develop hands-on experience with mechatronics technologies.

Professional projects, on the other hand, are typically driven by industry needs and involve the development of commercial products or systems. These projects showcase the application of mechatronics in real-world settings and often result in innovative solutions that transform industries.

Conclusion

Mechatronics Engineering has emerged as a pivotal field, combining the principles of mechanics and electronics to create innovative solutions. As discussed throughout this article, the interdisciplinary nature of mechatronics has led to significant advancements in various sectors, including industrial automation, consumer electronics, and automotive systems.

The integration of artificial intelligence, machine learning, and the Internet of Things (IoT) has further enhanced the capabilities of mechatronics systems. As we look to the future, it is clear that mechatronics will play a crucial role in shaping the technological landscape. The mechatronics conclusion is that this field will continue to evolve, driving innovation and transforming industries.

In summary, the mechatronics summary highlights the importance of this field in driving technological advancements. With its strong foundation in mechanical and electronic systems, mechatronics is poised to address the complex challenges of the future. The future of mechatronics holds much promise, with potential applications in emerging technologies and industries.